October 3, 2018

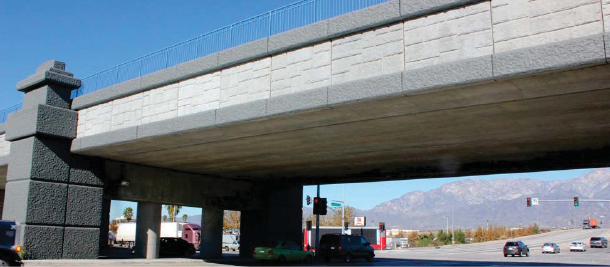

NORTH MILLIKEN AVENUE UNDERPASS

Value Engineering Redesign

Ontario, California

DESIGN & CONSTRUCTION TEAM

General Contractor: CC Myers Inc.

Owner: City of Ontario Design

Engineer: T. Y. Lin International El Cajon, CA

Oldcastle Infrastructure Precast Product(s): Precast Concrete Fascia Beams Prestressed Box Girders

Oldcastle Infrastructure: Perris, CA

2014 DESIGN AWARD WINNER: BEST NONHIGHWAY BRIDGE

Located less than a quarter mile (400 m) south of a major freeway interchange, this busy railroad crossing is at the nexus of a significant freight and commercial truck corridor. Prior to construction, truck traffic exiting the freeway had to back up onto the freeway when a train blocked the grade crossing, causing major delays and a significant safety hazard.

Initially, the design featured a steel plate girder bridge with a steel plate forming the deck, says Jay Holombo of T Y. Lin International, the engineer of record of the redesigned underpass bridge. During the bidding phase an alternate superstructure design using precast prestressed concrete adjacent box girders was evaluated. The new underpass includes a two-span bridge measuring 171 ft long × 52 ft wide (52 × 16 m). A precast concrete T-wall based retaining wall system extends a half a mile (800 m) in either direction on both sides of the tracks to elevate the line while meeting right-of-way requirements.

THE SOLUTION

The redesigned two-span underpass bridge consists of 26 precast, prestressed box girders supporting ballast, waterproofing, and two mainline tracks. Ballast curbs were cast as an integral component of the exterior girders. Each span is transversely post tensioned at the quarter points within each span. Each 4-ft-wide box girder contains fifty-six 0.6-in.-diameter strands and relatively thick bottom and top flanges of 9 and 10 in., respectively, to meet the stringent American Railway Engineering and Maintenance-of-Way Association (AREMA) strength, service, and deflection requirements. A net upward permanent deflection of 3 in. at midspan was anticipated after placement of ballast. A buildup of rubberized asphalt was used to ensure sufficient transverse and longitudinal slope to maintain drainage off of the bridge.

Fascia beams are conventionally, used to support pedestrian walkways and communication conduit. To minimize the amount of formliner needed, the precast fabricator developed an innovative approach where the exterior was cast as 7.5-ft-long panel segments. These precast panel segments were then placed in the forms and cast with the rest of the fascia box girder, resulting in significant savings while meeting the aesthetic requirements of the project.

The benefit of using a precast concrete box-girder superstructure is that bridge maintenance painting operations are not required, as would be necessary for the as-designed steel girder system.

The value-engineering redesign of the North Milliken Avenue Railroad Underpass Bridge demonstrates that high-performance precast concrete is ideal for railroad bridge spans greater than 80 ft, and has better economy and faster production than equivalent steel spans. The City of Ontario and the surrounding community further benefited from an accelerated construction schedule and reduced future maintenance costs.

KEY PROJECT ATTRIBUTES

- Precast box beams demonstrated significant cost savings and reduced fabrication time while compared to steel plate girders

- Designers achieved faster delivery of the project with minimal effects on traffic

- Net savings to the project was approximately $900,000

PROJECT AND PRECAST SCOPE

- Project Cost: $5 million

- Bridge Length: 171 ft (52 m)

- 7 Feet deep (2.1 m) precast concrete fascia beams support maintenance walkways, railings, and communication conduit and precast, prestressed box girders

Find out more about Oldcastle Infrastructure Bridge Solutions.