Oldcastle FRP

The Oldcastle FRP family of enclosures are produced in a unique hybrid process bonding strong, polymer concrete rings with high-impact resistant fiberglass sidewalls, forming a monolithic body. Paired with polymer concrete lid, select units are suitable for light or heavy incidental traffic. Specifiers can meet expected load ratings while installers can handle and modify with ease.

Your Project Deserves Expert Attention

Overview

STRENGTH AND DURABILITY, CAREFULLY CRAFTED.

Oldcastle FRP is manufactured using a spray up method with even layers of fiberglass strands and resin

that are applied onto the mold. After being rolled to remove trapped air, we reinforce the enclosure with

woven cloth applied between layers. This process ensures our high impact resistance and durability.

Features

LIGHT ON WEIGHT, NOT ON PERFORMANCE.

LIGHTWEIGHT

Oldcastle FRP features a lightweight design allowing for easier, safer handling and installation. The unique sprayup fiberglass manufacturing method paired with the polymer ring creates a strong, lightweight product.

STRONG

Strength and durability are key features to the Oldcastle FRP family. The reinforced fiberglass sidewalls are high-impact resistant, providing a superior solution to a common challenge in this market.

EASILY FIELD MODIFIABLE

Oldcastle FRP allows for easy field modification with common power tools. Contractors and installers can modify these enclosures quickly with ease.

ROBUST OFFERING

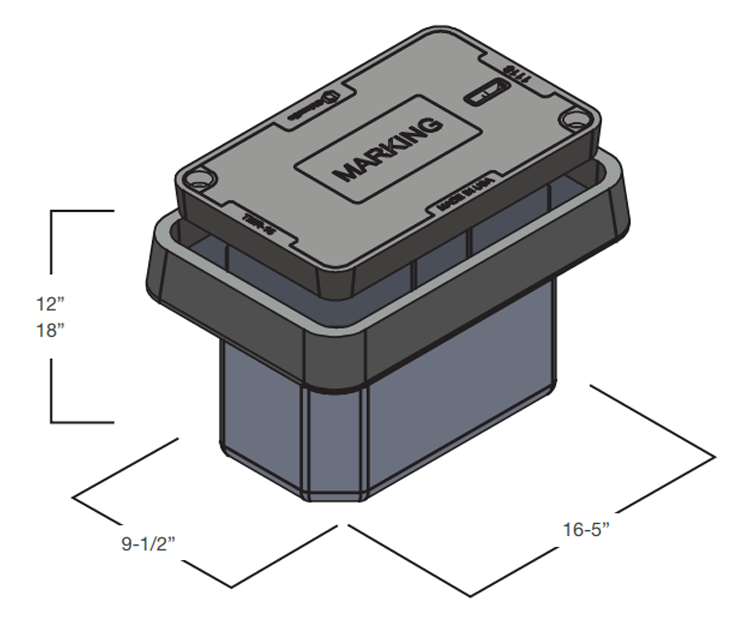

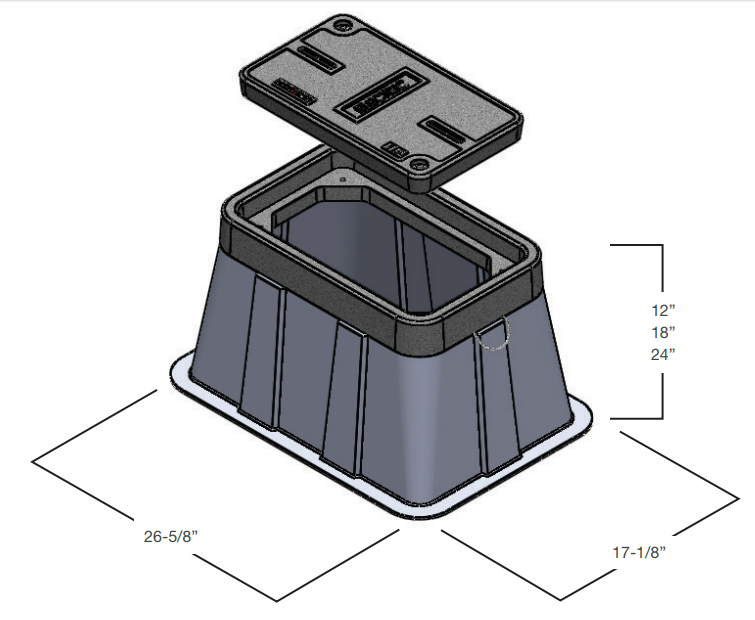

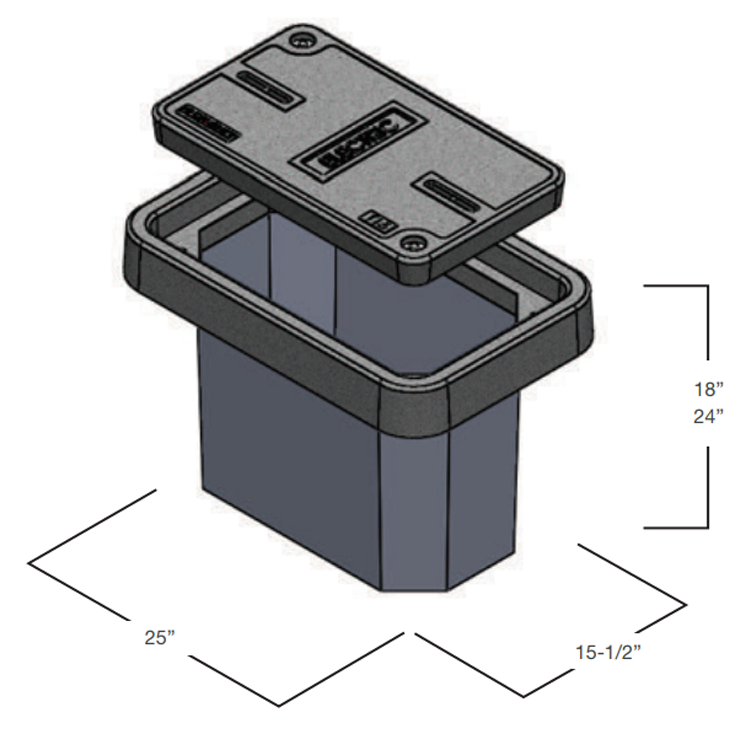

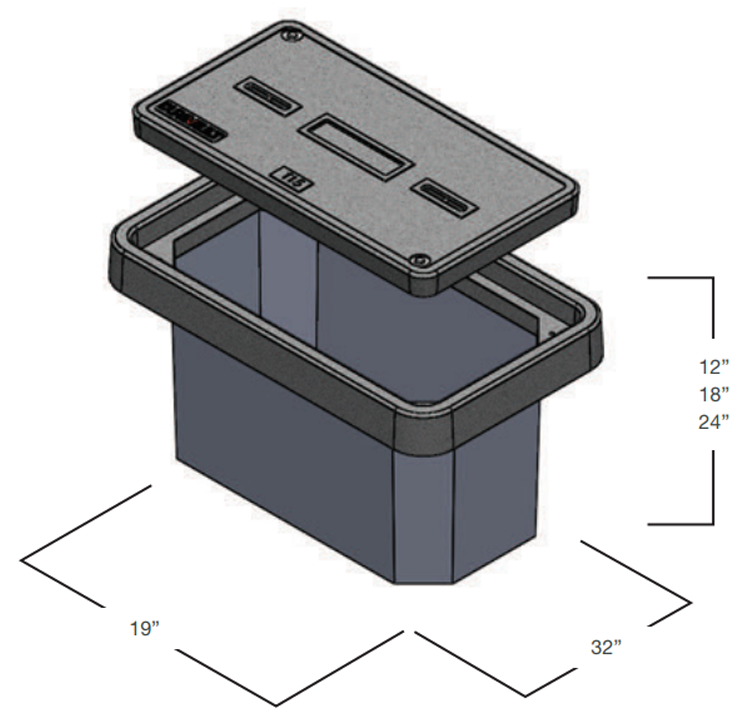

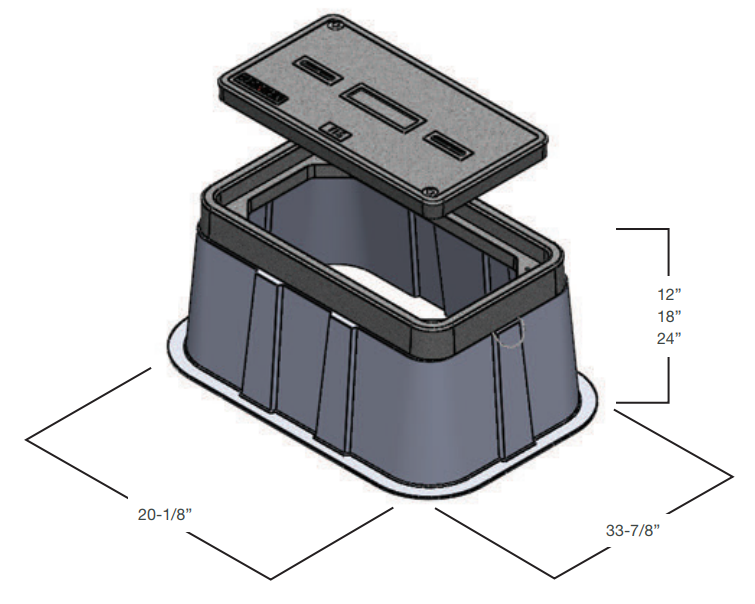

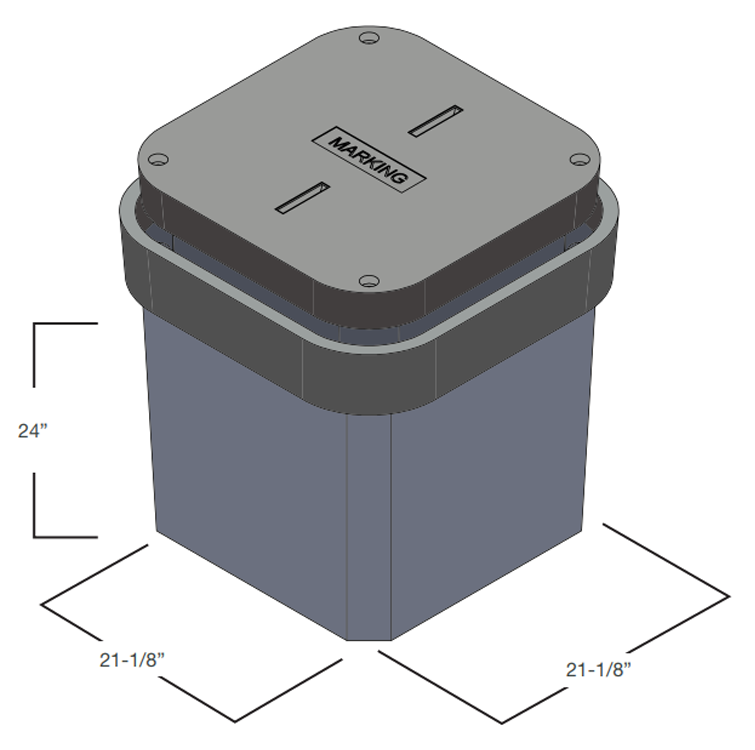

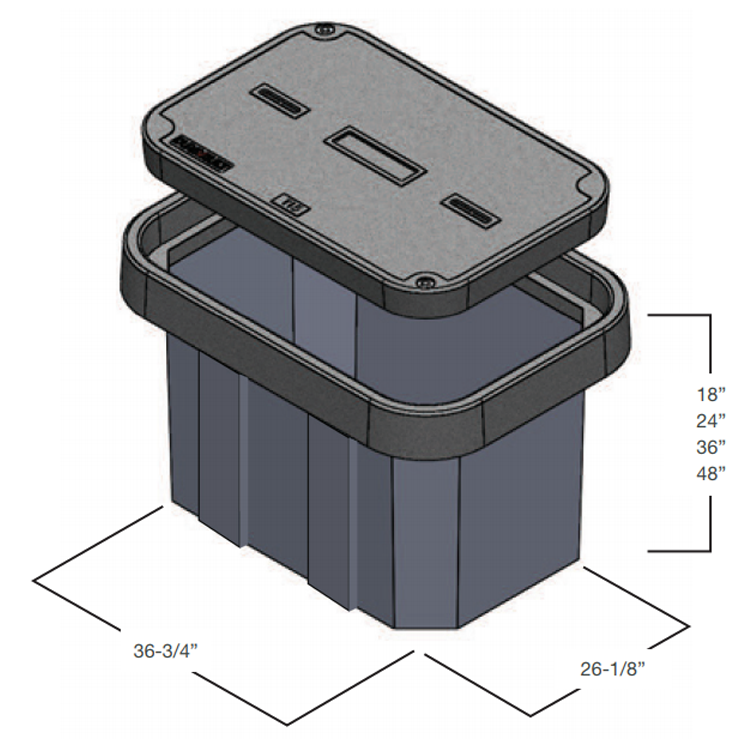

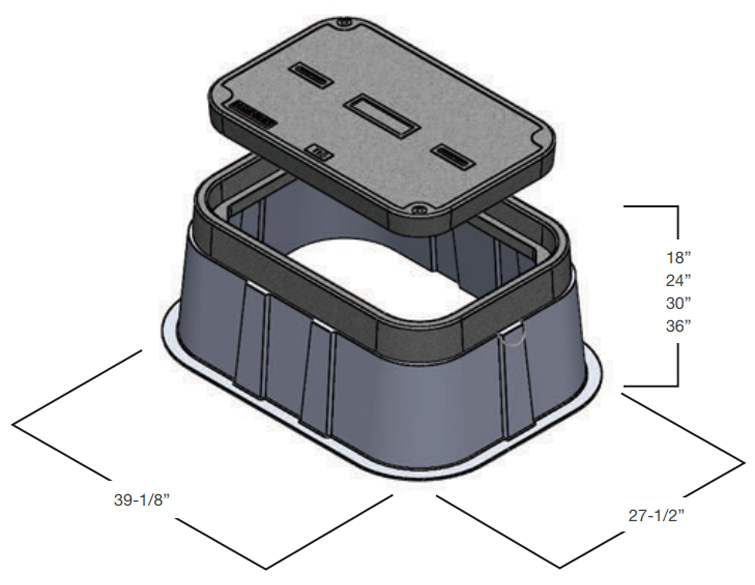

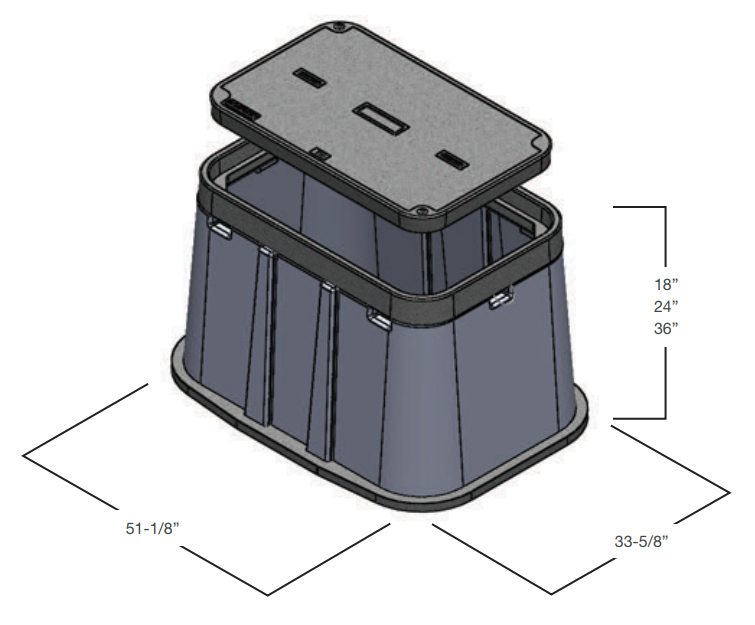

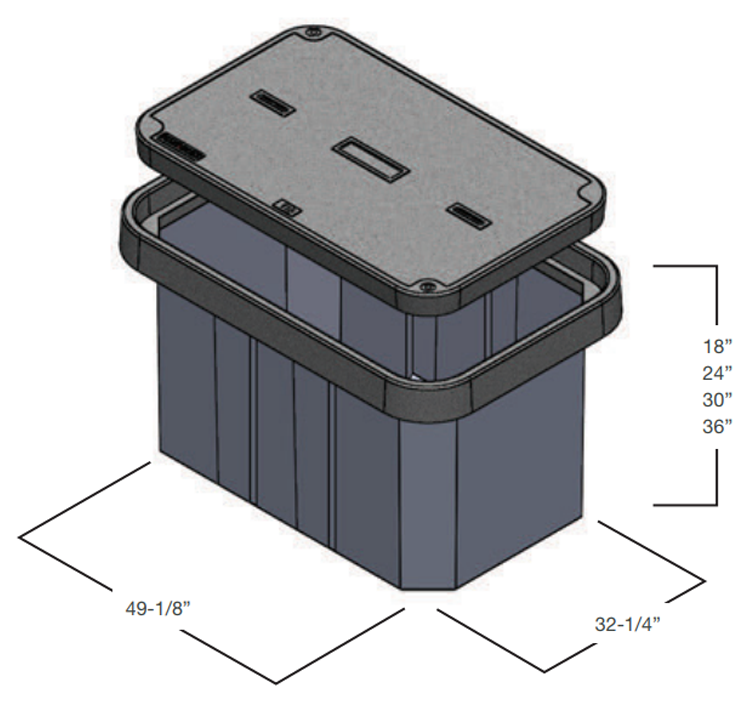

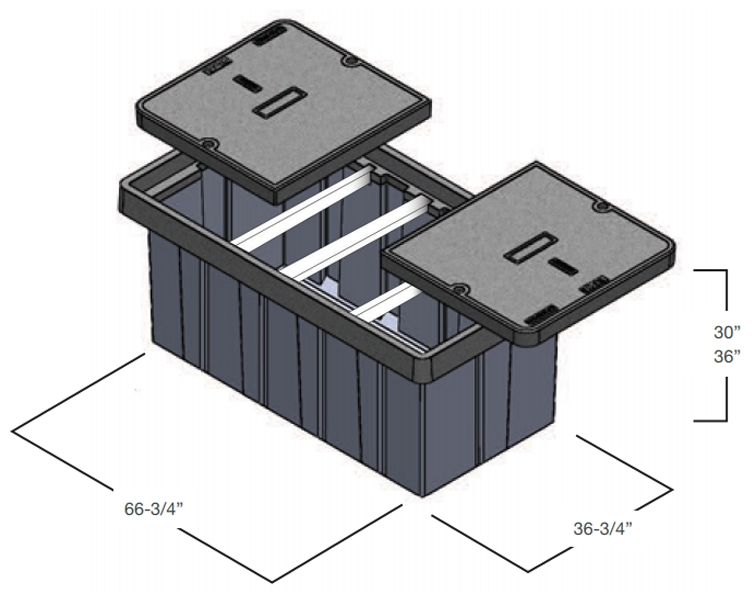

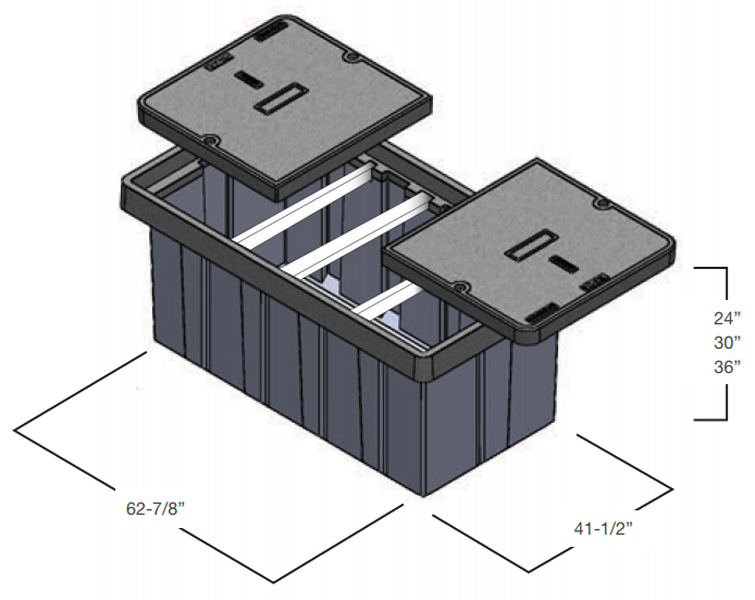

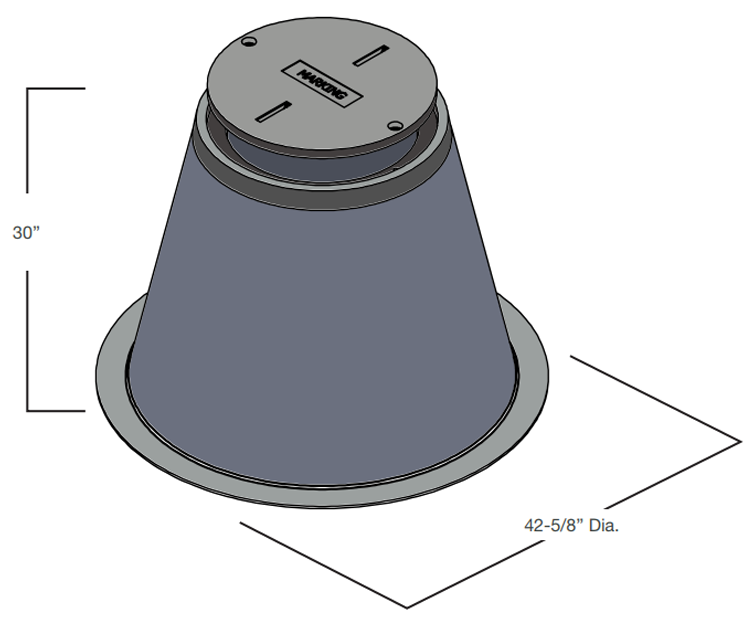

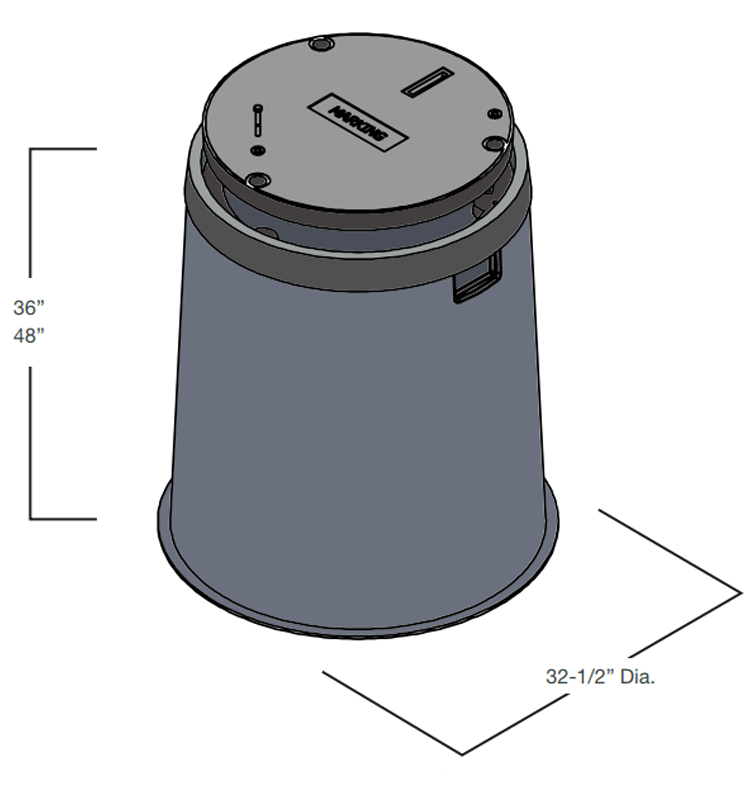

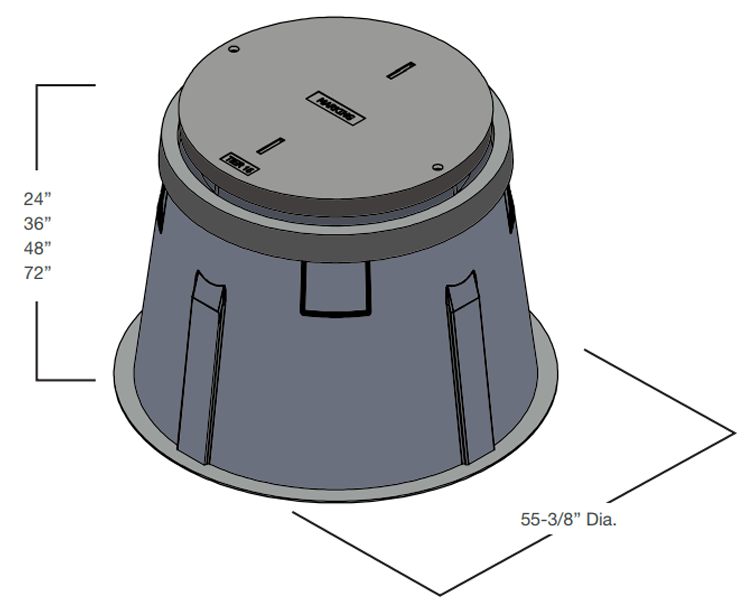

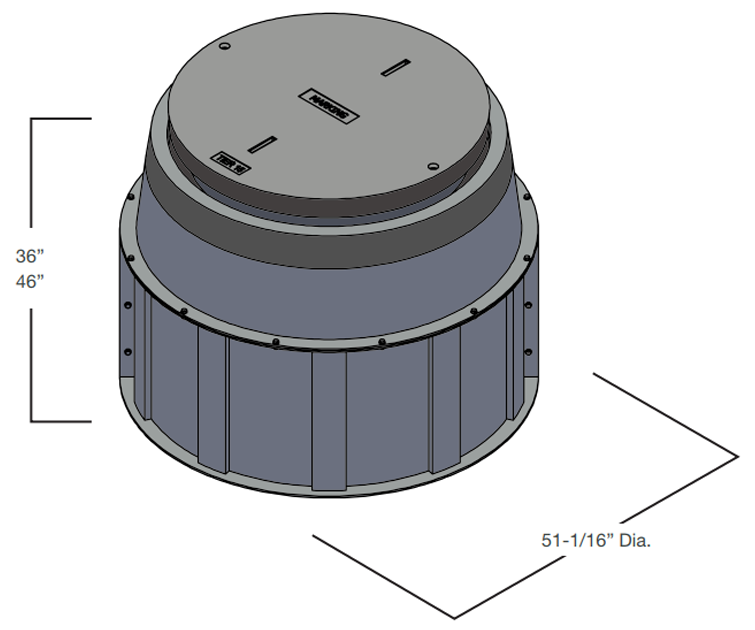

We understand that variety is important to meet the various needs of your projects, and Oldcastle FRP is available in a broad range of sizes and depths to provide the right enclosure for your project.

Specs & Downloads

Helpful Information

Brochures

- pdfOldcastle FRP Brochure

- pdfLarge Water Meter Solutions

Product Sheets

- pdfUnderground Enclosures Line Card

Installation Guide

- pdfUnderground Enclosures Installation Guide

| Name | Model | Height | Width | Length | Diameter | Downloads | Quote Generator | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Oldcastle FRP 1118 | 18” | 11” | View | Add | ||||||

|

Oldcastle FRP 1324 Flared | 24” | 13” | View | Add | ||||||

|

Oldcastle FRP 1324 | 24” | 13” | View | Add | ||||||

|

Oldcastle FRP 1730 | 30” | 17” | View | Add | ||||||

|

Oldcastle FRP Flared 1730 | 30” | 17” | View | Add | ||||||

|

Oldcastle FRP 2424 | 24” | 24” | 24” | View | Add | |||||

|

Oldcastle FRP 2436 | 36” | 24” | View | Add | ||||||

|

Oldcastle FRP Flared 2436 | 36” | 24” | View | Add | ||||||

|

Oldcastle FRP Flared 3048 | 48” | 30” | View | Add | ||||||

|

Oldcastle FRP 3048 | 48” | 30” | View | Add | ||||||

|

Oldcastle FRP 3060 | 60” | 30” | View | Add | ||||||

|

Oldcastle FRP 3660 | 60” | 36” | View | Add | ||||||

|

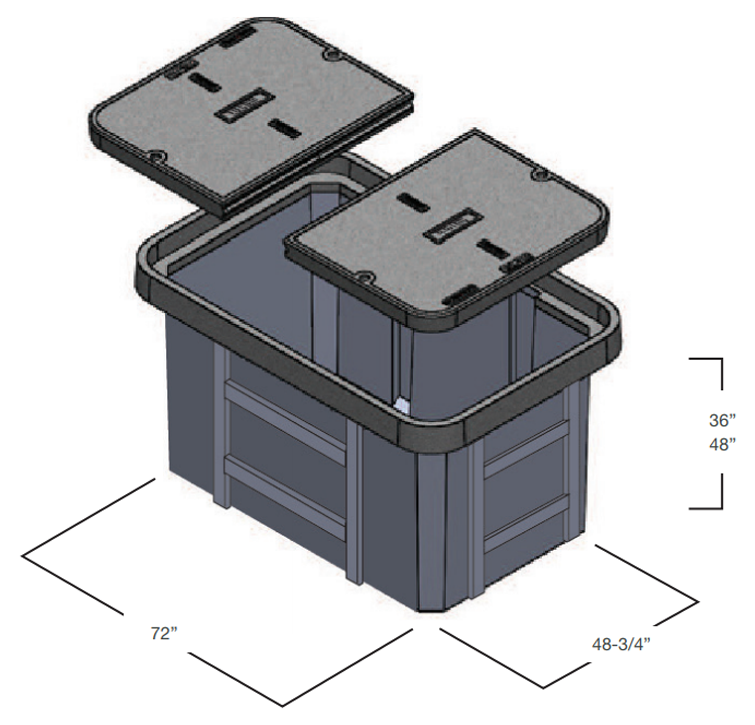

Oldcastle FRP 4872 | 72” | 48” | View | Add | ||||||

|

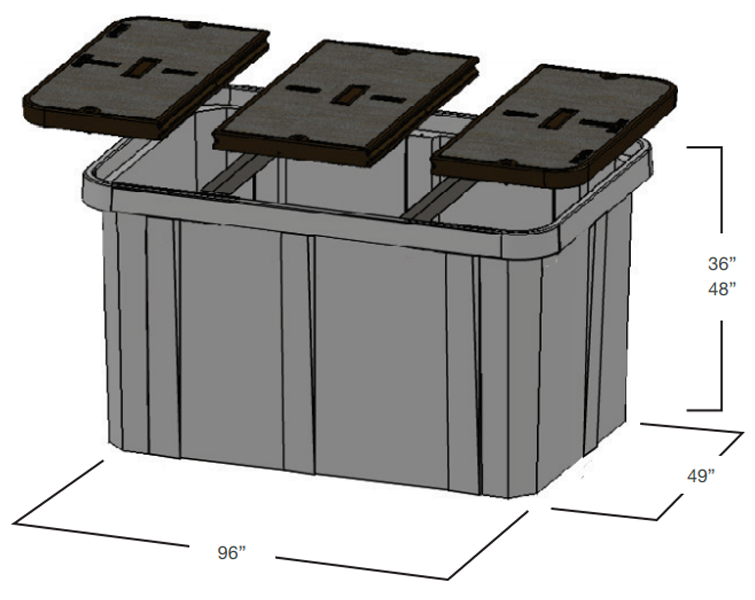

Oldcastle FRP 4896 | 96” | 48” | View | Add | ||||||

|

Oldcastle FRP 1000 | 18” | ” | ” | 10” | View | Add | ||||

|

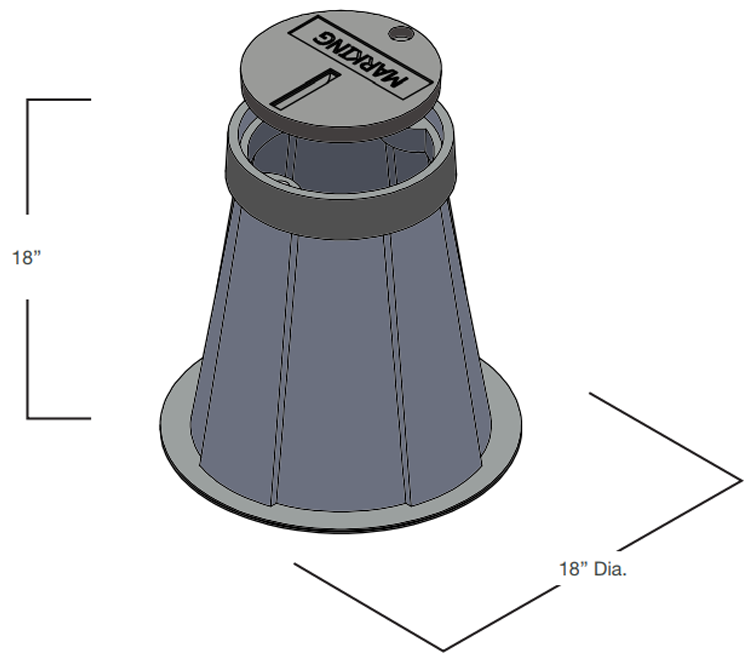

Oldcastle FRP 1800 | ” | ” | 18” | View | Add | |||||

|

Oldcastle FRP 2200 | 30” | ” | ” | 22” | View | Add | ||||

|

Oldcastle FRP 2700 | ” | ” | 27” | View | Add | |||||

|

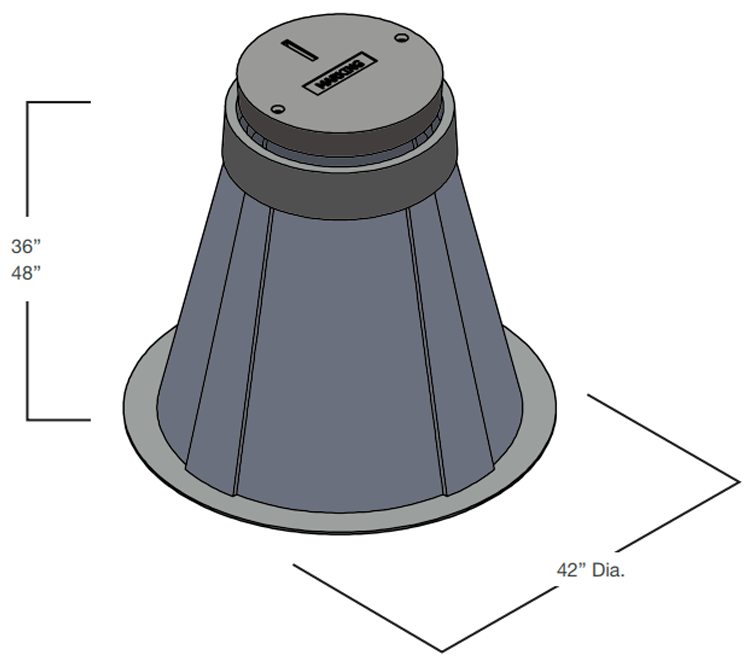

Oldcastle FRP 3900 | ” | ” | 39” | View | Add | |||||

|

Oldcastle FRP 5400 | ” | ” | 51” | View | Add | |||||

|

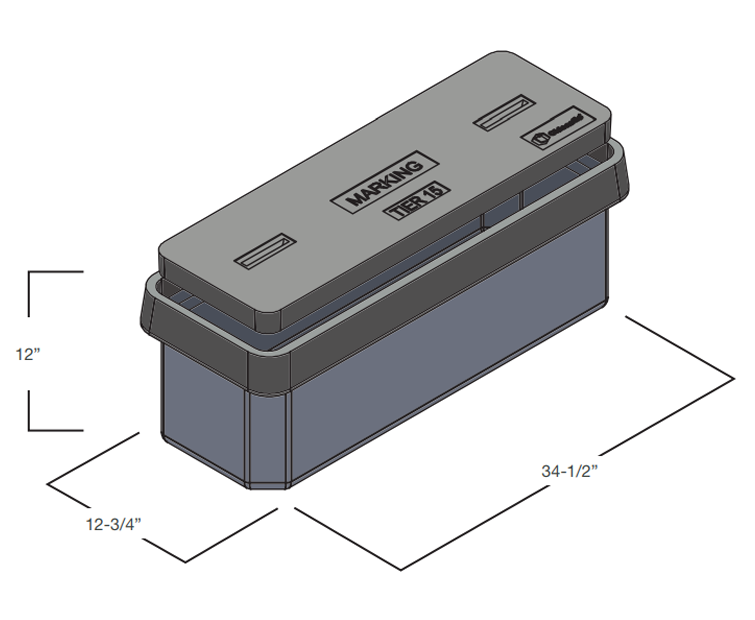

Oldcastle FRP 1132 | 12” | 32” | 11” | View | Add | |||||