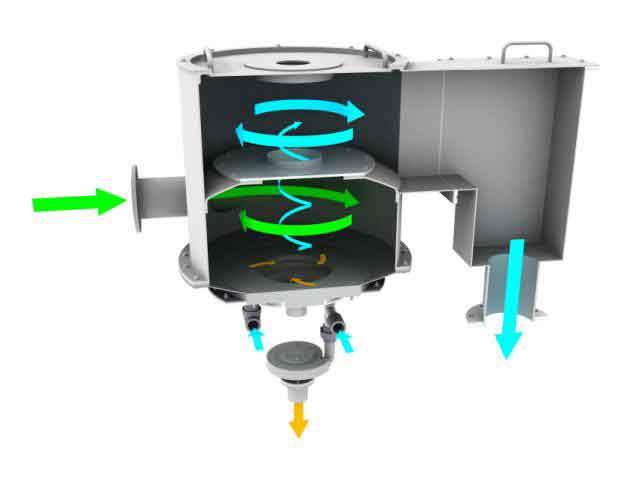

The SlurryCup™ is extremely effective at washing grit captured at the preliminary treatment stage by the grit channel, aerated grit chamber, vortex grit collector, or grit separator. The cleaned grit produced by the SlurryCup™, when dewatered by a Grit Snail®, contains 60% total solids with less than 15% organic solids in headworks applications, reducing the cost of solids handling and haulage to solid waste disposal sites, as well as reducing odors and associated aesthetic complaints.

With no internal moving parts, the SlurryCup™ is a low-maintenance, high-performance grit removal system that delivers effective grit washing, separation and classification.

Your Project Deserves Expert Attention

Looking for a quote for your project?

While browsing our products, select “Add to Quote Generator” to quickly get an estimate for everything you need.