Grit Snail®

The Highest Capacity Grit Dewatering System Just Got a Major Upgrade

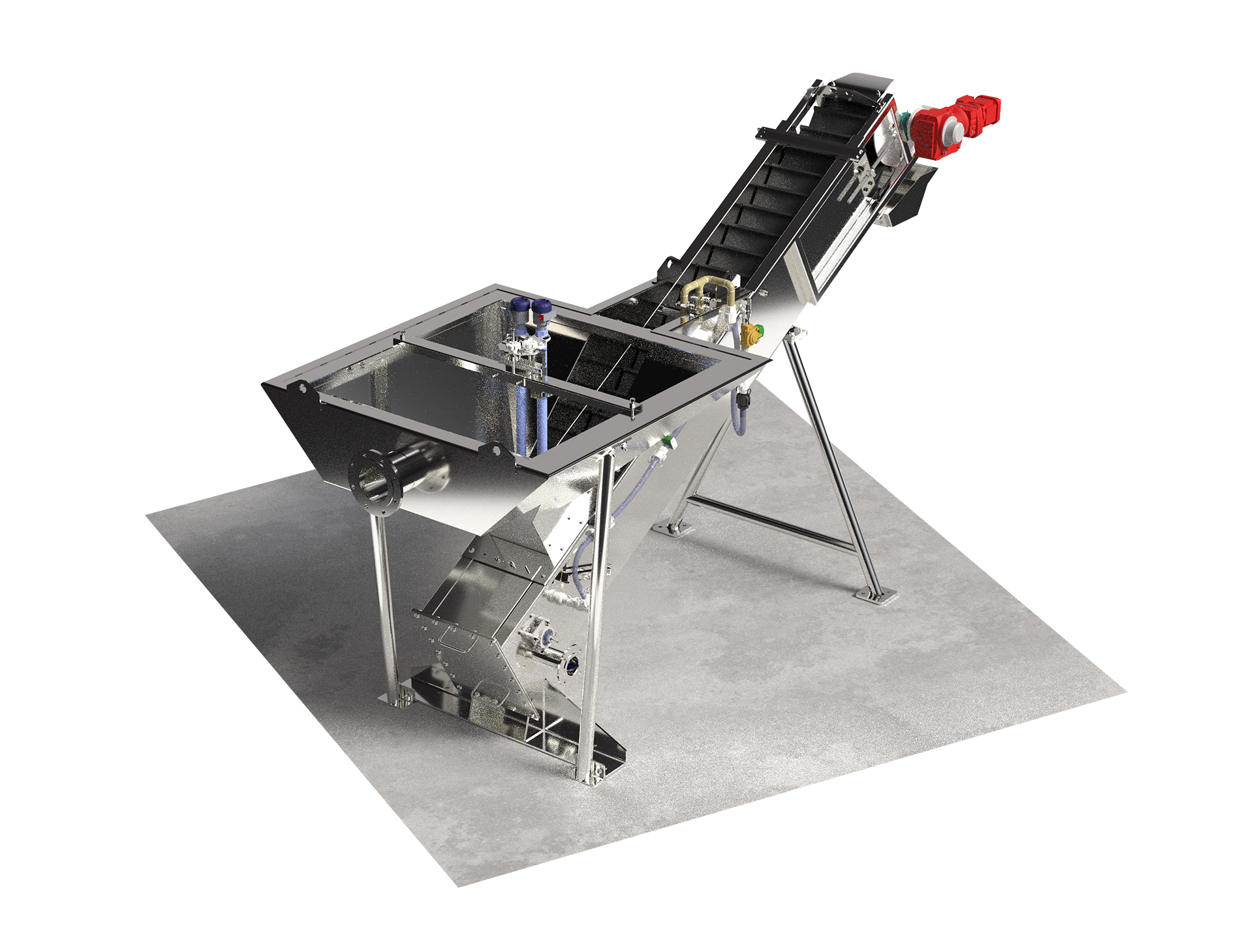

Grit Snail® is like no other grit dewatering technology, it is built specifically to address the challenges of fine grit. It is the only belted grit dewatering system on the market, giving it many unique advantages. A slow moving belt maximizes retention of fine grit while offering the highest solids handling capacity on the market at up to 10 yd3/hour (4.5 ft3/min or 7.6 m3/hr).

Overview

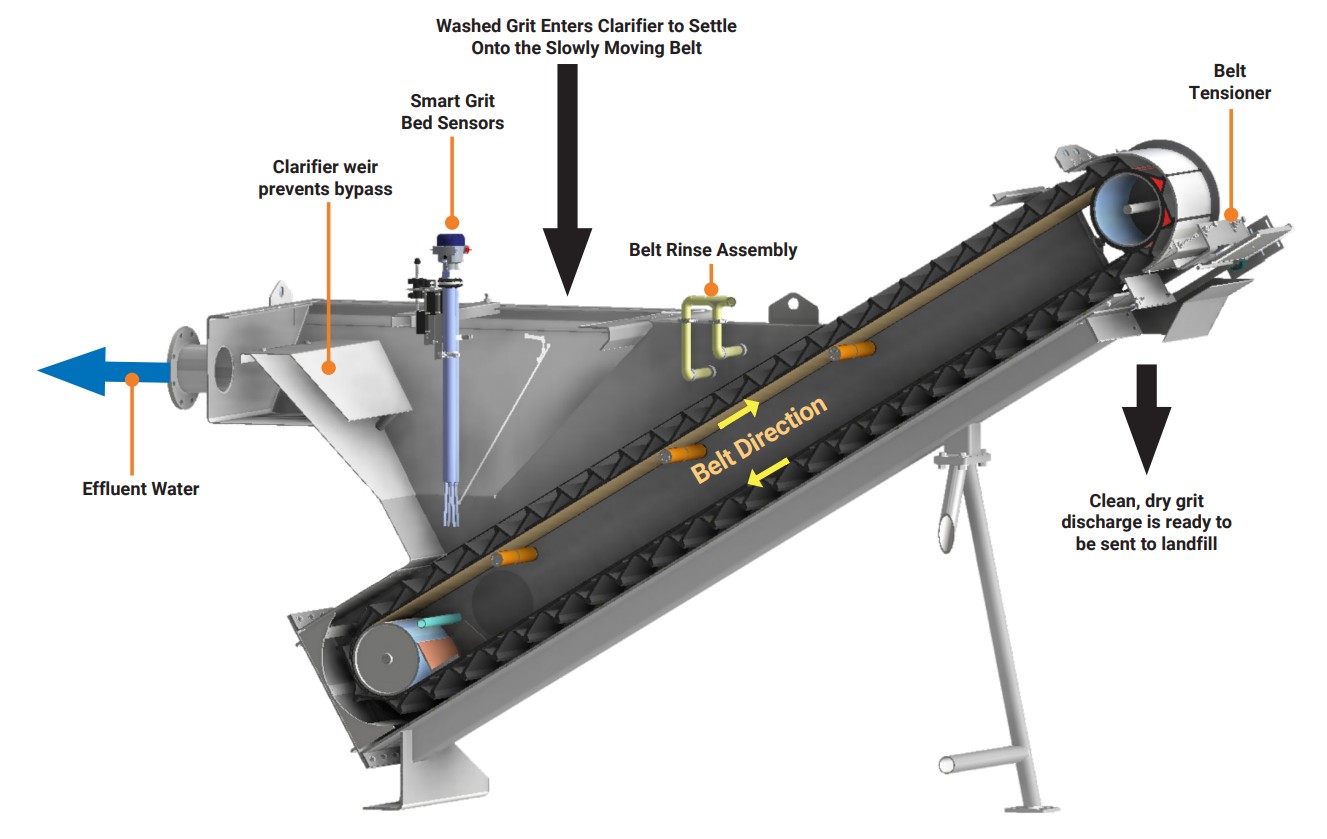

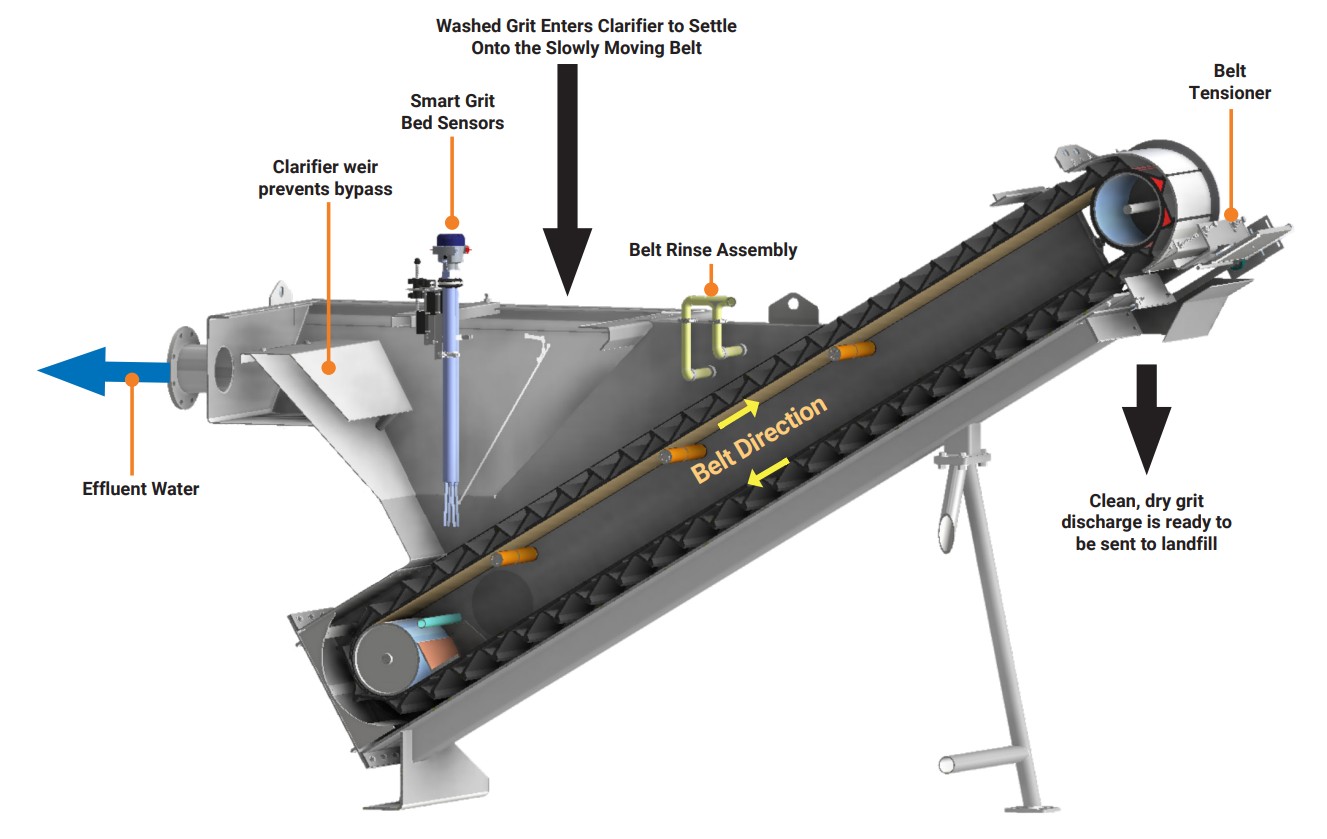

The Grit Snail® uses a slowly moving cleated belt to gently escalate grit from the clarifier pool without re-suspending fine grit particles which will cause the grit to escape with the clarifier overflow.

Applications

- Grit dewatering for municipal WWTPs

- Dewaters grit output from a SlurryCup™, OpTeaCup®, or Grit King® unit

- Sludge degritting or headworks dewatering applications

- Agricultural and industrial applications

Proven Grit Snail® Performance Just Got Better

Engineered by Hydro International, the Grit Snail® has over 700 installations throughout the Americas. As a result, the Grit Snail® has been tested and proven to perform under a wide variety of operating conditions. Now as part of Oldcastle, we’ve taken all the lessons we’ve learned through the years and re-evaluated the system from the inside out. The result is a significantly improved product designed to dramatically simplify maintenance, minimize downtime, and extend the longevity of the entire system.

Key improvements include:

- Significantly reduced maintenance system-wide

- Easier to change belt, with improved supports to extend belt life

- Enhanced component durability and improved gasketing

The Grit Snail® uses a slowly moving cleated belt to gently escalate grit from the clarifier pool without re-suspending fine grit particles which will cause the grit to escape with the clarifier overflow.

Applications

- Grit dewatering for municipal WWTPs

- Dewaters grit output from a SlurryCup™, OpTeaCup®, or Grit King® unit

- Sludge degritting or headworks dewatering applications

- Agricultural and industrial applications

Proven Grit Snail® Performance Just Got Better

Engineered by Hydro International, the Grit Snail® has over 700 installations throughout the Americas. As a result, the Grit Snail® has been tested and proven to perform under a wide variety of operating conditions. Now as part of Oldcastle, we’ve taken all the lessons we’ve learned through the years and re-evaluated the system from the inside out. The result is a significantly improved product designed to dramatically simplify maintenance, minimize downtime, and extend the longevity of the entire system.

Key improvements include:

- Significantly reduced maintenance system-wide

- Easier to change belt, with improved supports to extend belt life

- Enhanced component durability and improved gasketing

Benefits

Retain more, finer grit

Many conventional grit removal systems will combine washing and dewatering into a single process. Washing is a turbulent process, however, and dewatering should be performed under still conditions; combing these processes is why many types of systems fail to retain fine grit. Agitation from a combined washing / dewatering process can churn up finer grit allowing it to escape with water exiting the system. The Grit Snail® is a quiescent system with a slow-moving belt that eliminates this kind of turbulence, meaning that it retains more, finer particles.

Reduce operating costs

When paired with Hydro International separation and/or washing systems—such as the HeadCell®, Grit King®, SlurryCup™, OpTeaCup®, or TeaCup®—the Grit Snail® retains fine grit and produces cleaned material with very low volatile solids and residual moisture. This reduces odor and makes the output easier to handle and dispose of. By dewatering grit effectively, treatment plants can avoid the unnecessary cost of landfilling excess water and organic content.

- Non-turbulent process retains even the smallest grit particles

- Durable 304 or 316 stainless steel construction ensures long service life

- Large clarifier with a low overflow rate provides sufficient settling time

- Dewaters large quantities of grit while retaining particles as small as 75 µm

How it Works

A washed grit slurry is discharged into the Grit Snail® clarifier. The clarifier is sized to provide sufficient area for particles as small as 75 micron (µm) to settle. Degritted effluent water overflows a weir and goes on to the next treatment process. The captured grit settles to the bottom of the clarifier and onto the belt. The slowly moving belt gently lifts accumulated grit from the clarifier bottom without re-suspending it, eliminating the potential for carry-over. The belt typically moves at 1–2 feet per minute (30–60 cm per minute), which creates quiescent dewatering conditions.

The grit settles onto the stepped cleats and is gently lifted out of the clarifier pool. Dewatering begins as the grit and fine abrasives are slowly raised from the clarifier. The dewatered abrasives are carried to the top of the Grit Snail®, where they are discharged into a container for disposal. The lined belt housing, stepped rubber belt cleats, and no metal-to-metal contact ensure long component life and minimal wear. The variable frequency drive adjusts belt speed to match changing grit loads.

Performance

The Grit Snail® removes 95% of all grit 75 micron and larger at the design flow rate when used with an Oldcastle Infrastructure grit washing system. It removes 60% total solids and less than 15% volatile solids when used with Oldcastle’s SlurryCup™, TeaCup®, or OpTeaCup® washing units.

Capacity

- Dewatering capacity from 1 to 10 yd3/hr (0.7 to 7.7 m3/hr) of grit

- Clarifier sizes from 48″ to 96″ (1.2 to 2.4 m) square

- Belt widths from 6″ to 57.5″ (0.15 to 1.5 m)

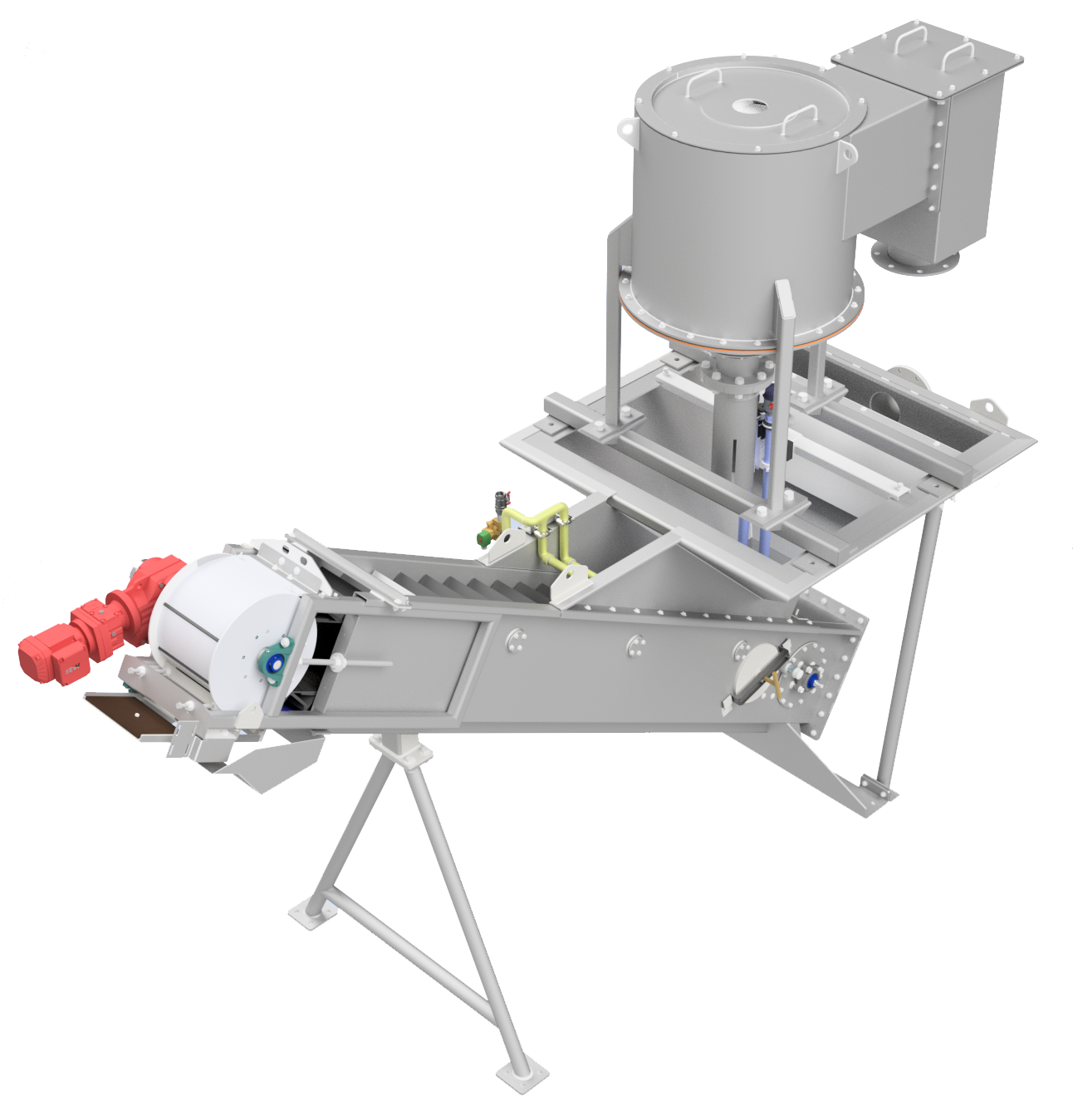

Configurations

- The Grit Snail® can be configured to match most applications as the clarifier is sized for flow while the belt is sized for grit load

- The SlurryCup™ (or TeaCup®) / Grit Snail® system can be used for headworks degritting or to degrit concentrated slurry captured from a HeadCell® or a Grit King® separation system

- Multiple inlet and outlet arrangements are available to accommodate plant piping conditions

FAQ

Q. When should we use a Grit Snail and when should we use a Decanter for a dewatering system?

A. Larger plants will typically require a Grit Snail® system, while in many smaller plants a Grit Decanter system will provide the required dewatering performance more economically. Please contact us to determine whether a Grit Snail® or Grit Decanter dewatering system would be the optimal choice for your plant.

Q. Can the Grit Snail be used with grit removal devices from other manufacturers?

A. No, the Grit Snail® is designed specifically for dewatering clean grit output from Oldcastle Infrastructure’s high-performance separation and washing devices. Other systems will output grit with high organic content and cannot be dewatered by a Grit Snail®. Alternative systems typically do not capture the fine grit particles that the Grit Snail® is designed to retain and would not require the outstanding performance and dewatering capacity of the Grit Snail®.

Q. What are the advantages of the Grit Snail?

A. Many conventional grit removal systems combine washing and dewatering in the same process. This introduces turbulence, which stirs up captured fine grit particles, allowing them to be released with the effluent water. The Grit Snail® is used exclusively for grit dewatering. The slowly moving belt of the Grit Snail® pulls solids from the clarifier water without agitating the water, thereby retaining even very fine grit particles.

Specs & Downloads

- pdfBrochure