Grit King® Compact

Advanced Grit Management® priced for smaller plants unwilling to sacrifice performance

Overview

Hydro International now offers small wastewater treatment plants an accessible option to deliver 95% removal of all grit entering the plant for peak flows up to 6 Mgal/d (27 MLD). See flow / performance chart on bottom right.

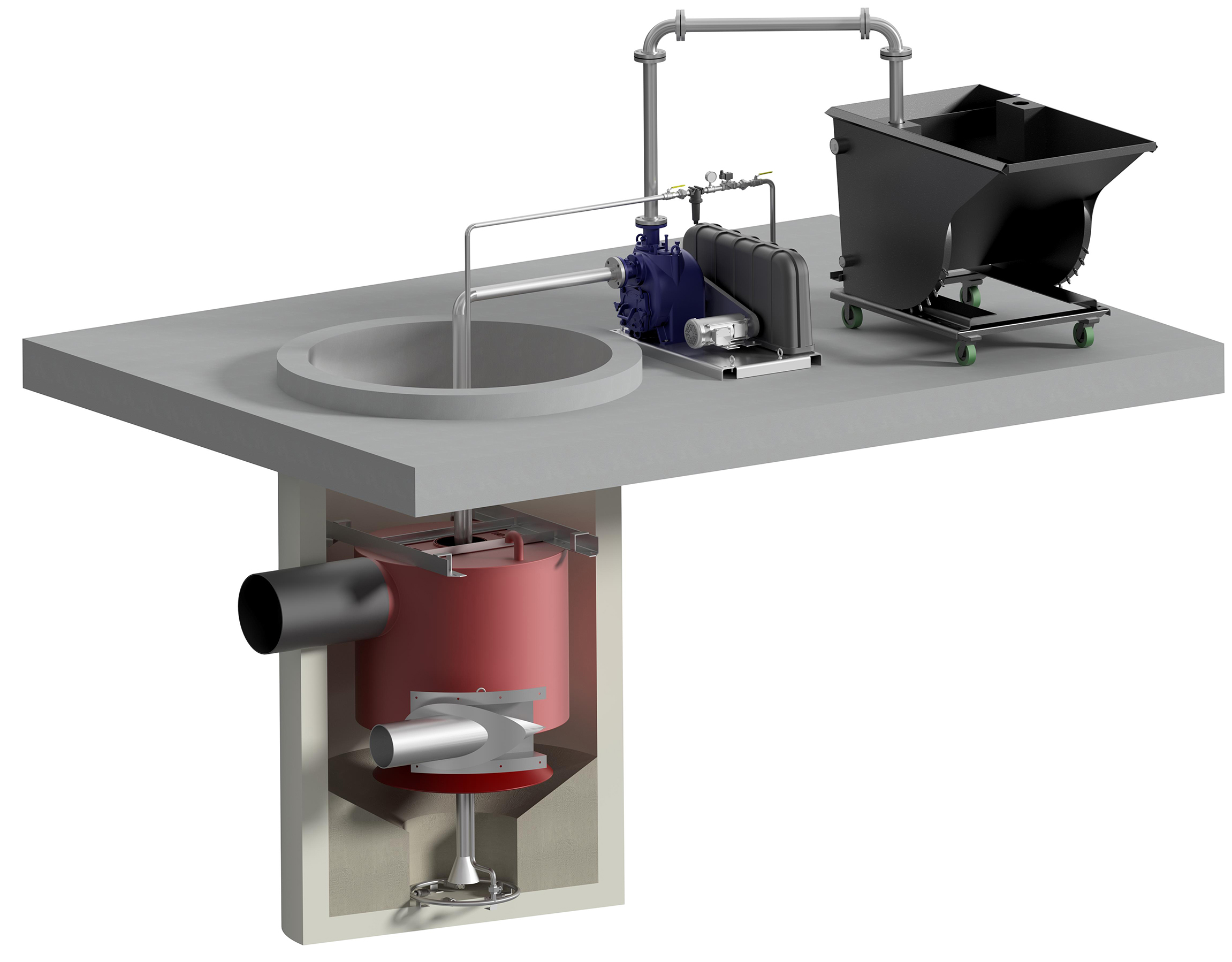

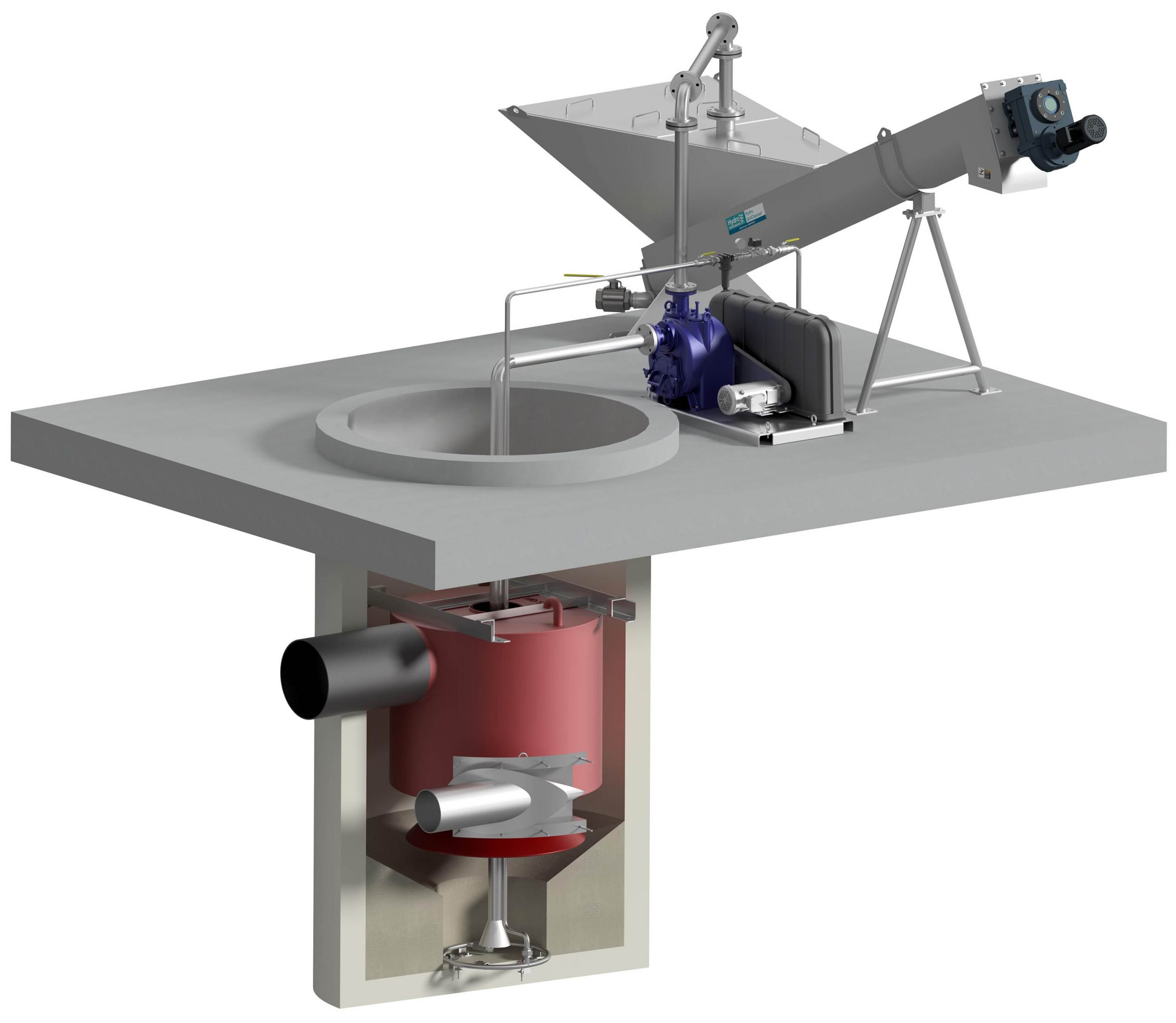

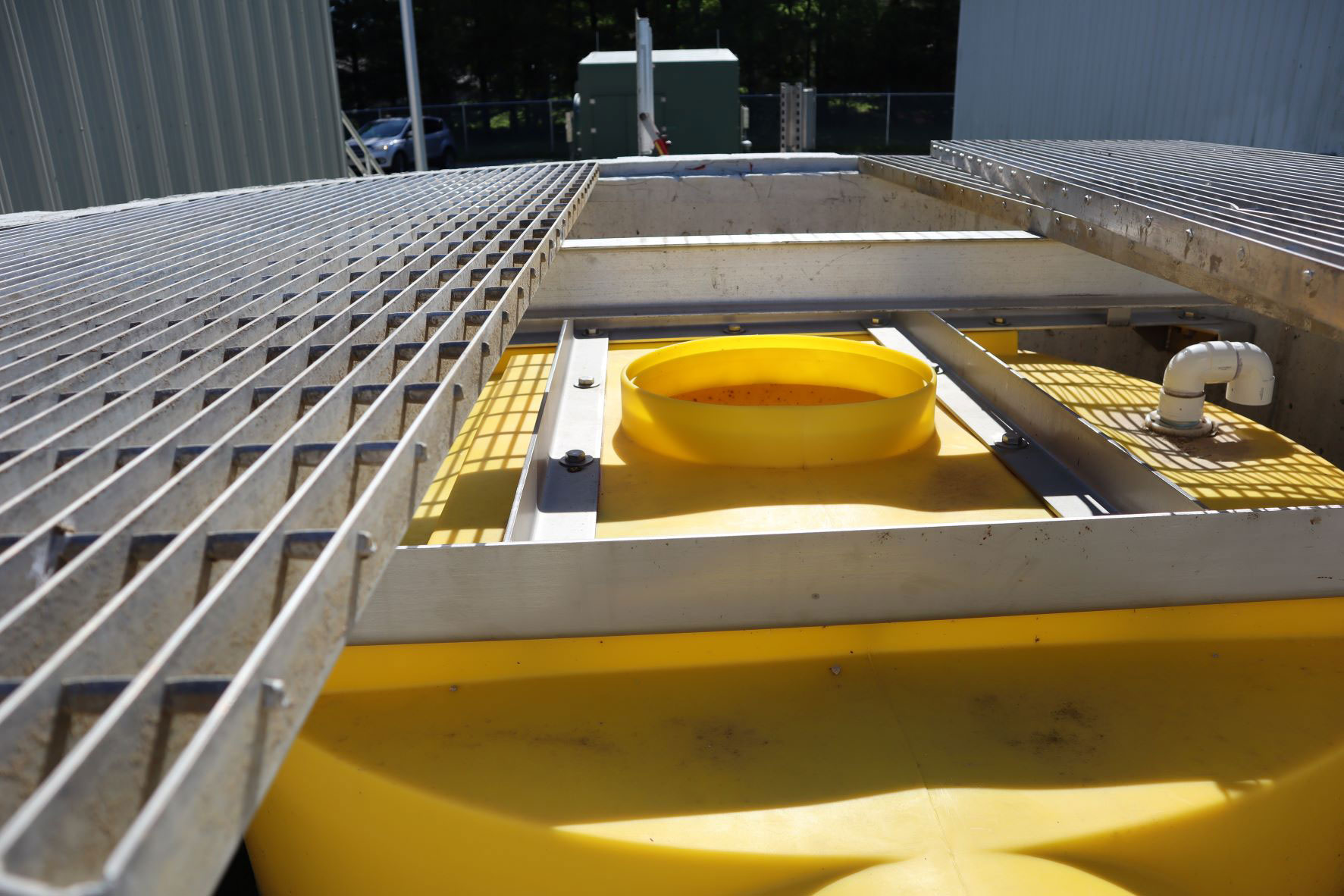

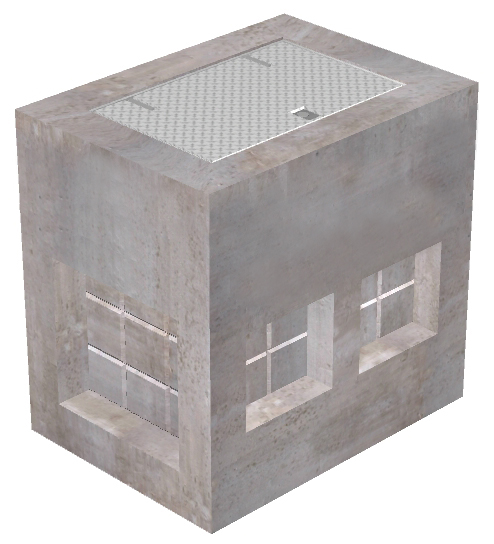

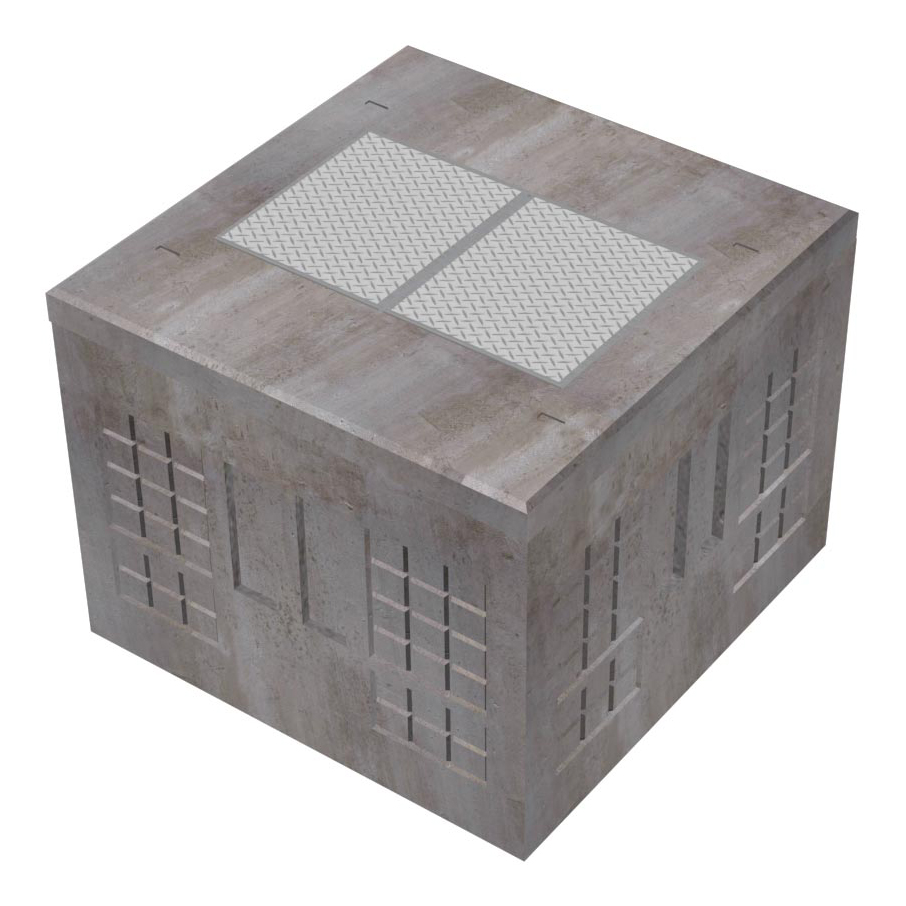

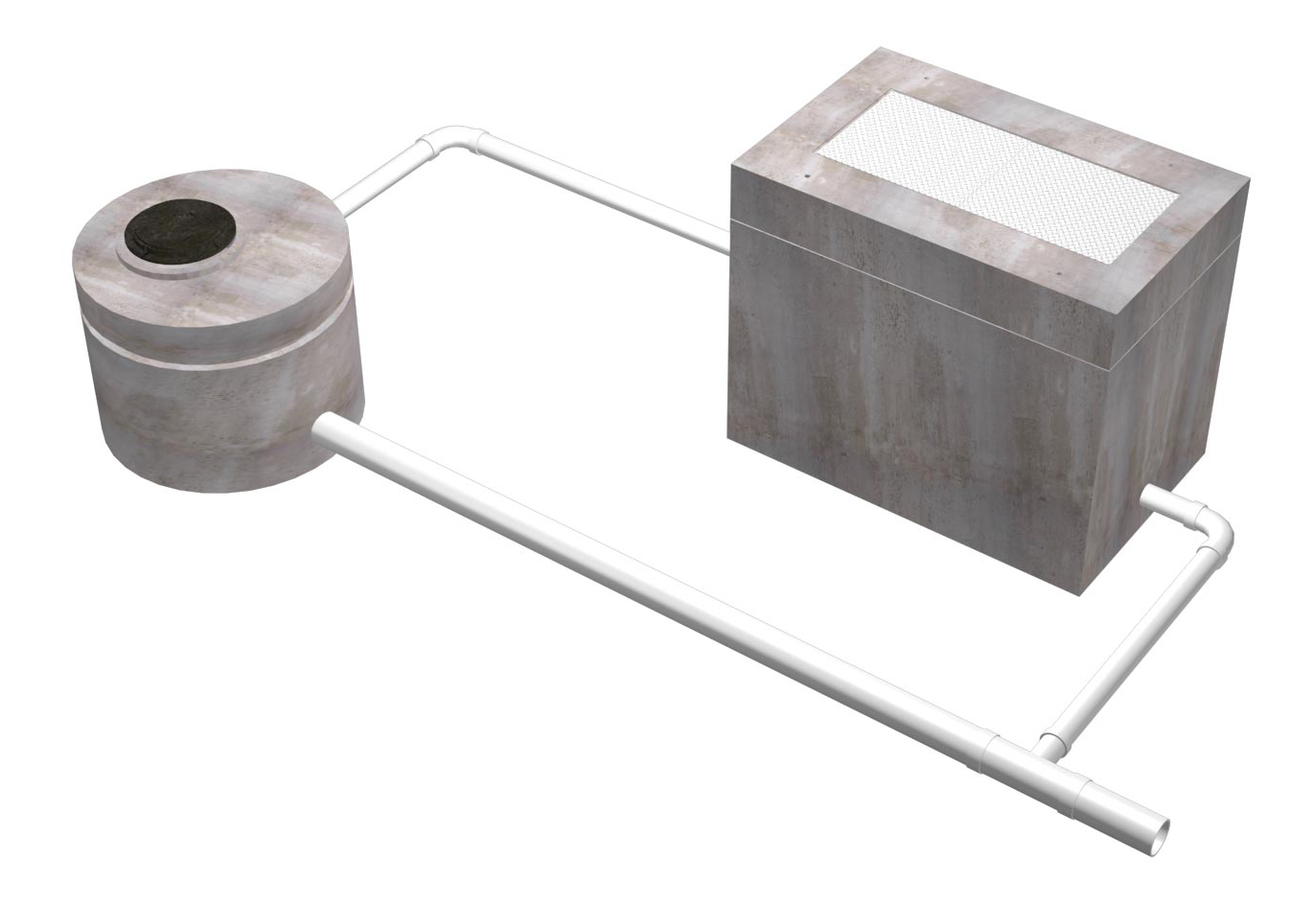

Advanced Grit Management® systems, have often been a luxury item for small plants – until now. Grit King® hydrodynamic vortex separation is now available with synthetic internal elements specifically tailored for small plants. The system can be placed in a poured concrete tank and a grout cone is formed in the bottom. The internal components, made of synthetic materials and stainless steel, are installed with inlet and outlet connections. Typically provided with a dry pit or self-priming grit pump, Decanter grit dewatering box, and a control panel to complete this Advanced Grit Management® system.

About

Applications

- New small municipal and industrial wastewater treatment plants

- Small treatment plant retrofits and upgrades

- Sediment removal for potable water

Benefits

- Economical to install, own, and operate

- A complete Advanced Grit Management® system including collection and dewatering

- No moving parts in the separator, the grit pump is the only mechanical component

- Compact design with minimal headloss

Performance

The Grit King® Compact can be designed for a range of performance targets to suite the needs of the plant. 95% removal of all grit 106, 150, 212 or 300 µm and larger

How it Works

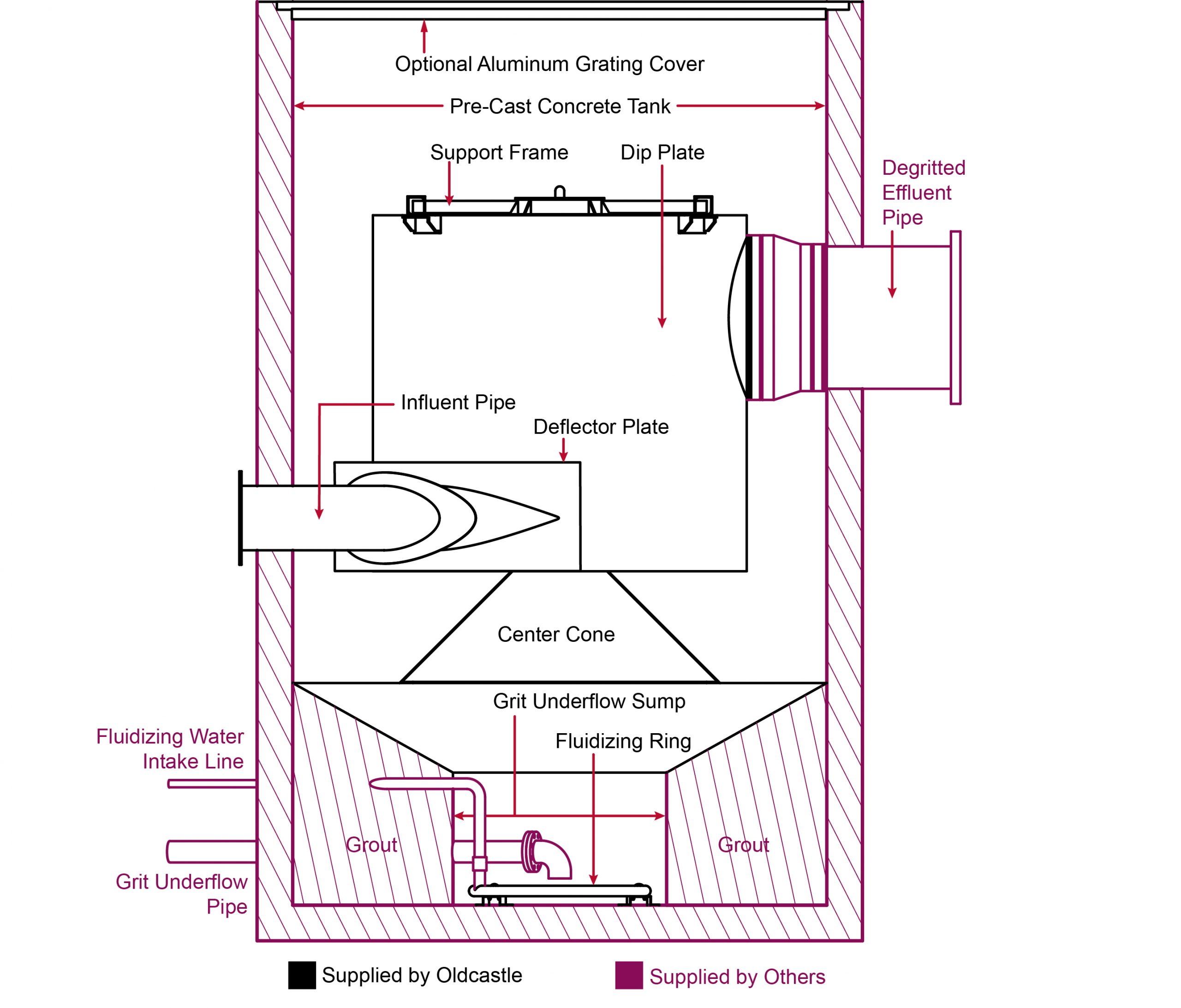

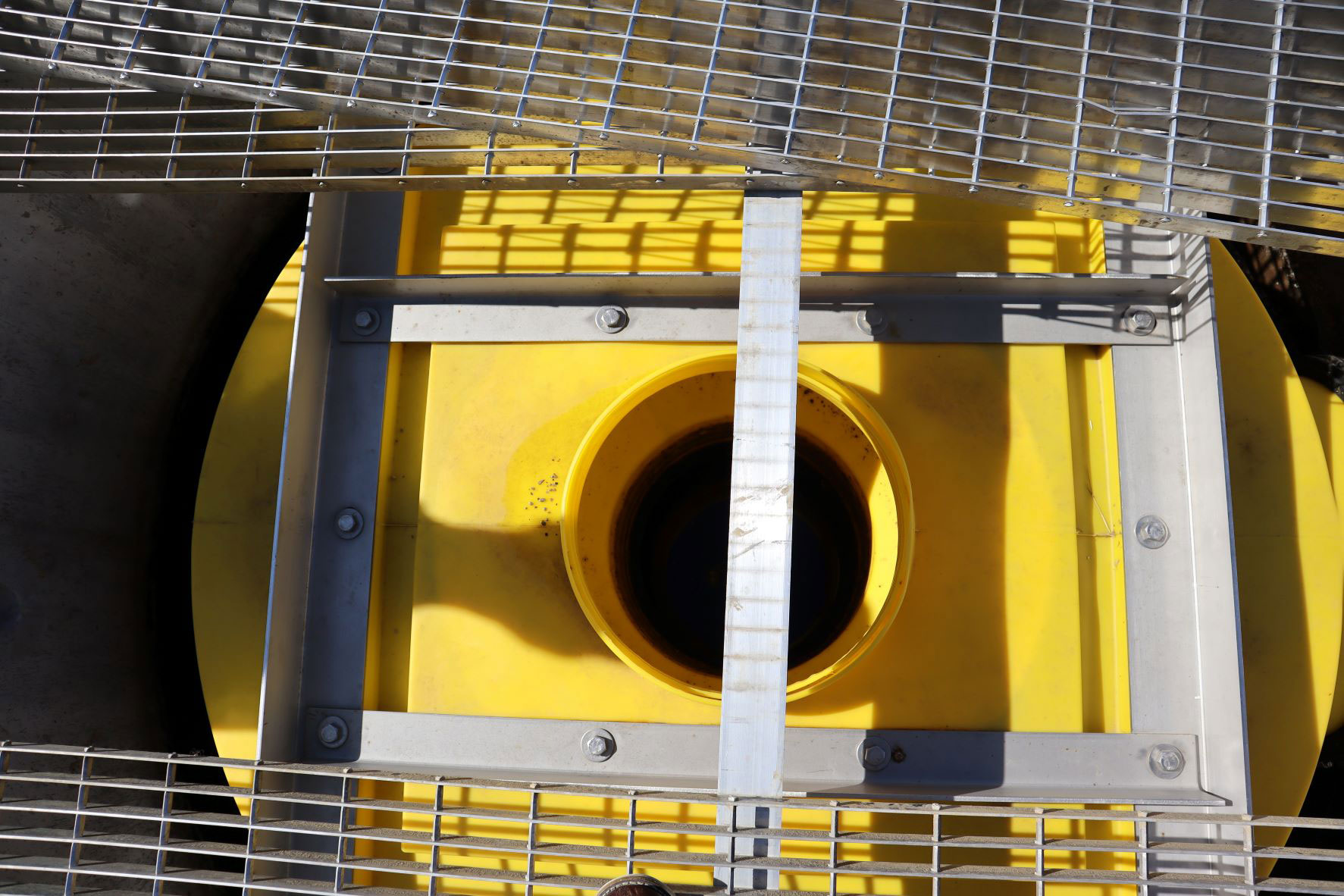

The Grit King® is an advanced hydrodynamic separator that augments gravitational forces to effectively separate grit from water with no moving internal components. Flow is introduced into the Grit King® via a tangentially positioned inlet causing a rotational flow path around the dip plate. The flow spirals down the wall of the chamber as solids settle out by gravitational forces and forces created by the rotating flow. The grit collects in the grit sump at the bottom of the unit as the center cone directs flow away from the base, up and around the center shaft into the inside of the dip plate and out the effluent pipe.

The upward flow rotates at a slower velocity than the outer downward flow. The resulting “shear” zone scrubs out the finer particles. The concentrated grit underflow is pumped to a grit dewatering dumpster.

Configurations

The synthetic internal components and stainless steel support frame are supplied with this system. A grout cone is formed in the bottom of a concrete tank, components are installed and sealed connections are made to the influent and effluent piping.

The Grit King® Compact is typically supplied with a dry pit or self priming grit pump, controls and a Decanter non-mechanical dewatering bin. Alternative grit dewatering options are available.

Downloads

Helpful Information

Product Information

- pdfGrit King® Compact Brochure

Media

Search Term:

Concrete

High-Flow Bypass Manhole – Sizes Vary

Model: Hi-Flow Bypass Manhole - size varies

MFG Plant: Wilsonville, OR