Hydro GritCleanse

Cut landfill costs and reduce odor issues with cleaner, drier grit.

Every wastewater treatment plant faces unique local conditions – we’ll help you meet your site-specific requirements. Schedule a presentation or find your local wastewater treatment expert.

Overview

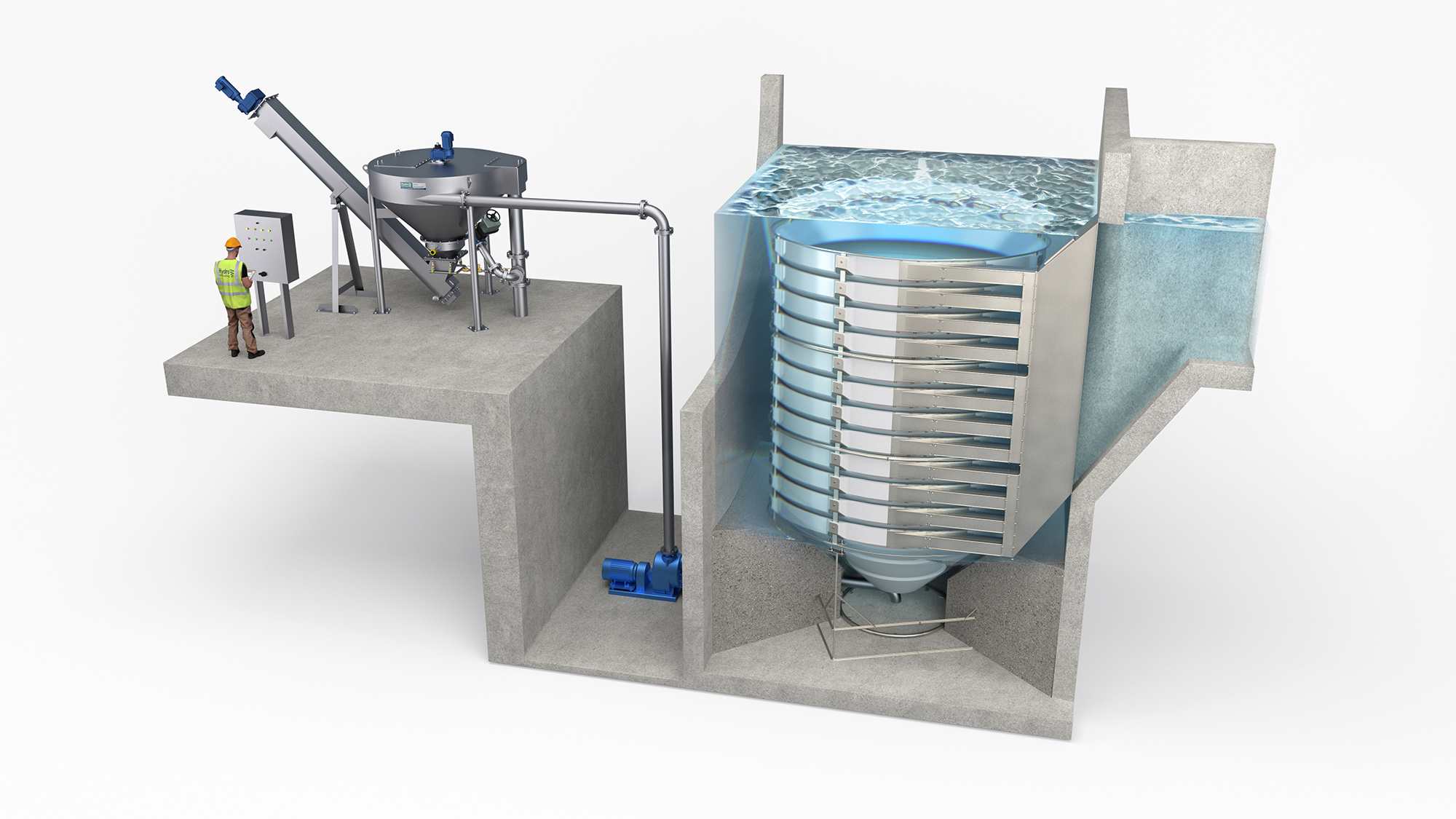

The Hydro GritCleanse™ is a fluidized bed grit washing and grit dewatering system that significantly reduces volatile volids (VS) content to produce cleaner, drier wastewater grit.

Cutting VS levels in wastewater grit product reduces weight, volume, and water content—which significantly reduces odor issues and saves you money on solids handling and disposal.

Engineered by Hydro International, the pioneers in fine grit removal, the Hydro GritCleanse™ retains 95% of all grit 75 micron and larger and outputs washed grit with less than 5% VS and is the only fluidized bed grit washing technology that can be offered with our industry-leading performance guarantee.

About

Applications

- Grit washing where very low volatile solids are required

- New wastewater treatment plants

- Treatment plant retrofits

- Replacement for worn out or ineffective grit washing and dewatering systems

Benefits

Reduced organics reduces operating costs

Reducing organic material in captured grit reduces volume, weight, water content and odors. Cleaner grit retains less moisture and allows it to drain away.

This results in less material that needs to be landfilled – significantly reducing disposal fees, hauling and handling fees and the resources needed to deal with it.

Single supplier accountability guarantees grit system performance

Bundled grit separation, washing, and dewatering from a single manufacturer simplifies maintenance and operational questions and provides a single point of contact to ensure that the entire grit removal process can protect your plant.

A single supplier eliminates finger pointing with different manufacturers blaming the others for any problems.

Oldcastle Infrastructure provides complete grit removal systems with no weak links. A single supplier also ensures that your entire grit removal system is always operating at peak efficiency with optimized performance.

Reduced odor = happy operators & neighbors

Disposing of grit is usually performed as a batch process, and grit is often left in open-air dumpsters until enough is collected to warrant disposal. High organic content grit can lead to significant odor issues and an unpleasant environment for operators.

The Hydro GritCleanse™ system outputs grit that has less than 5% Volatile Solids. Additionally, the Hydro GritCleanse™ is fully enclosed, further reducing odor issues.

Optimized to work with HeadCell® and Grit King® separation

The Hydro GritCleanse™ is the only fluidized bed grit washing system specifically designed to work with the industry’s best performing advanced grit separation systems the HeadCell® and Grit King® and is designed to fully capitalize on their phenomenal performance.

When a Hydro GritCleanse™ system is paired with our grit separation technology we can guarantee entire system grit removal performance.

Designed for easy maintenance

All stainless-steel construction and heavy-duty design ensures durability even in outdoor operation.

The Hydro GritCleanse™ uses a shafted screw design with an external lower bearing.Unlike classifiers with shaftless screws there is no need for liners or steel wear bars that often need to be cut out to be replaced, requiring a complete disassembly of the unit.

Instead, the Hydro GritCleanse™ is equipped with a long lasting 4-bolt lower bearing that can be accessed and serviced from the outside of the trough saving both money and downtime.

Shafted screw design reduces wear and eliminates the need to replace wear bars or liners. The dewatering screw pivots to allow easy access for maintenance.

Rinse water is injected via nozzles which are accessible externally. Other systems use neoprene membranes to introduce rinse water, but membranes are subject to fouling when using non-potable water. The membranes are also typically stacked within the screw/clarifier assembly which requires complete disassembly for maintenance.

Tangential feed improves performance

Feeding the clarifier at the tangent allows the Hydro GritCleanse™ to immediately put grit in direct contact with the clarifier surface and establishes a rotary flow pattern.

Grit is caught in the boundary layer as it settles to the bottom of the unit into the gently agitated fluidized bed.

Washers that feed at the clarifier center force the grit particles to travel a significant distance to reach the clarifier surface. This allows more opportunity for finer/slower settling grit to be carried out with the effluent.

How it Works

Flow is introduced tangentially into the conical clarifier forcing grit to contact the vessel walls creating drag forces and establishing a rotary flow pattern. Incoming grit settles into the low velocity boundary layer at the inside wall of the vessel. The structured, laminar flow pattern allows retention of fine and slowly settling grit particles while the interior baffle prevents short-circuiting.

Once in this boundary layer grit is further decelerated and settles to the bottom of the unit into the gently agitated fluidized bed where physical forces separate fixed and volatile solids by density. Grit settles to the bottom of the bed while the lighter organic material carries out with the effluent. Large organics remain in suspension at the top of the bed and are intermittently discharged via an adjacent port on a timed basis.

Washing occurs in the fluidized bed as organic material attached to the grit particles is scrubbed away due to friction between particles and the higher density grit descends to the bottom. Washed grit is discharged intermittently based on bed pressure via the dewatering screw.

Watch this animation to see how the Hydro GritCleanse™ works.

Technical Information

Performance

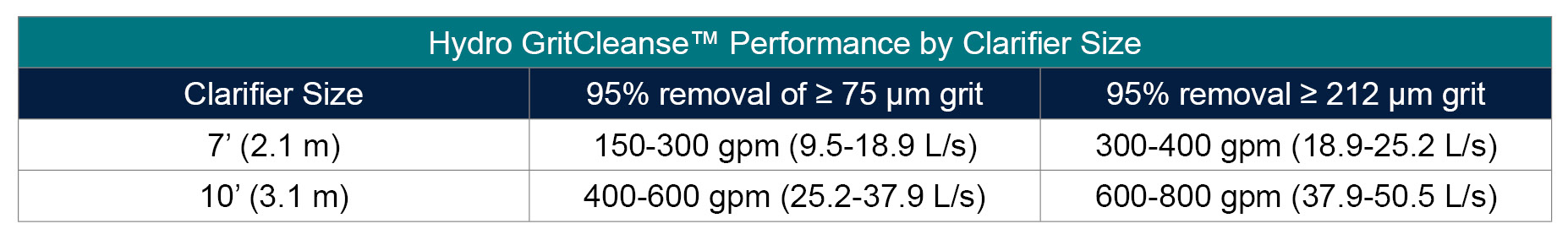

Oldcastle offers the Hydro GritCleanse™ in different sizes to accommodate our customers’ requirements and preferred balance between flow capacity and performance. Flow capacity and performance of our two most common system sizes is reflected in the following table.

Capacity

- Multiple sizes / capacities available

- Hydraulic capacity up to 800 gpm (50 L/s)

Downloads

Helpful Information

Product Information

- pdfHydro GritCleanse™ Brochure

Media

Search Term:

No results found

That's ok. We can still help!

- Try expanding your search radius

- Reduce your refinement filters

- Try searching for your product

- Contact a Representative and ask for product support