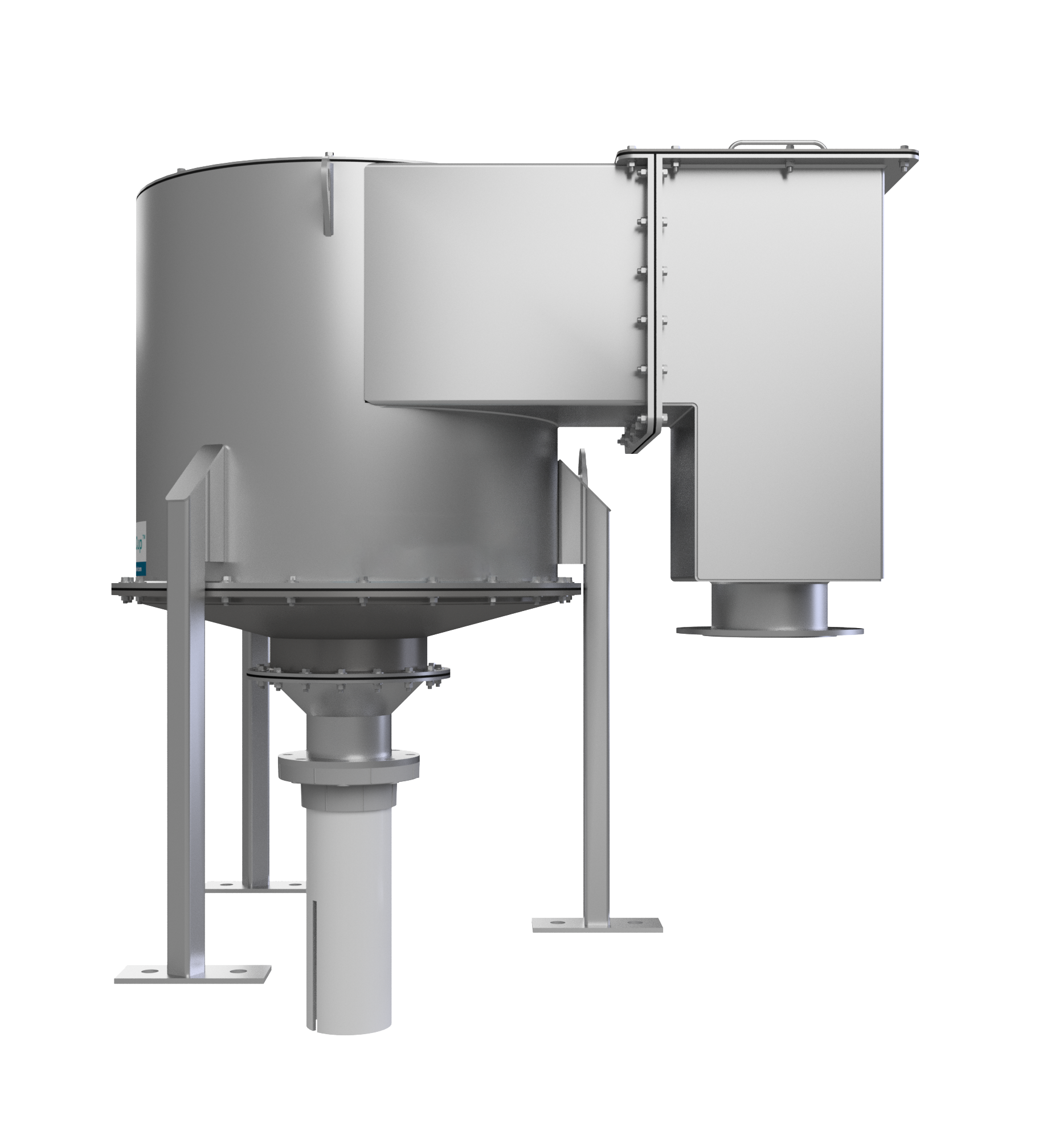

OpTeaCup®

Optimized TeaCup® Classifier / Concentrator

Every wastewater treatment plant faces unique local conditions – we’ll help you meet your site-specific requirements. Schedule a presentation or find your local wastewater treatment expert.

Overview

The OpTeaCup is the next generation of TeaCup® grit concentration and classification.

Based on Hydro International’s 40 years of experience with industry leading grit washing systems, the OpTeaCup was developed to address the needs of modern treatment plants.

Significantly expanded clearances prevent clogging from nuisance materials like flushable wipes and rags. Internal components have been minimized and streamlined further increasing throughput capabilities without reducing fine particle capture performance. The improved geometry eliminates the need for fluidizing water, actuated valves, or solenoids reducing utility requirements and maintenance.

An improved and easily accessible orifice plate simplifies long-term maintenance while also offering flexibility in how coarse organics are managed. Operators who prefer coarse organics (i.e. corn) to pass through to the bioprocess will utilize a smaller orifice which reduces organics going to dewatering.

Operators who prefer coarse organics be removed with the dewatered grit will utilize a larger orifice so this material exits with the OpTeaCup underflow.

About

Applications

- WWTP headworks grit classification / concentration

- Snail shell removal from trickling filters

- Grit system replacement and upgrades

- Potable water sediment removal pretreatment

Benefits

- Clear 4” (100 mm) diameter opening from top to bottom with no internal studs, exposed fasteners, or baffle plate prevent clogging from rags or wipes

- No actuated valves required, reducing maintenance

- No fluidizing water or solenoid valves required

- Easily accessible poly coated orifice plate allows for easy replacement and enhanced durability

- Adjustable underflow rate

- Replaceable orifice plate allows organics management flexibility

Performance

- Removes 95% of particles equal to or greater than 75 micron (µm) at the design flow rate

- Removes 95% of particles equal to or greater than 75 micron (µm) at the design flow rate

Capacity

- Handles flow of 200 to 400 gpm (13 to 24 L/s)

- 32” Size (0.8 m) diameter

- Solids concentration up to 1.5%

How it Works

Flow enters the stainless steel vessel tangentially at a controlled rate and\ velocity. The flow regime established in the device forms a free vortex which results in high centrifugal forces and a thin predictable boundary layer. Grit is forced to the outside perimeter or held in suspension until it falls by gravity into the boundary layer which sweeps the grit into the centralized discharge at the bottom of the unit.

Volatile solids are lifted from the bottom of the unit and ejected out the system overflow and returned to the WWTP for treatment. The concentrated grit slurry exits the bottom of the unit. Periodically, flow to the system is paused to allow the vessel to drain and pass any large solids that might have stalled within the system.

Configurations

- Inlet and outlet can be oriented to accommodate many piping configurations.

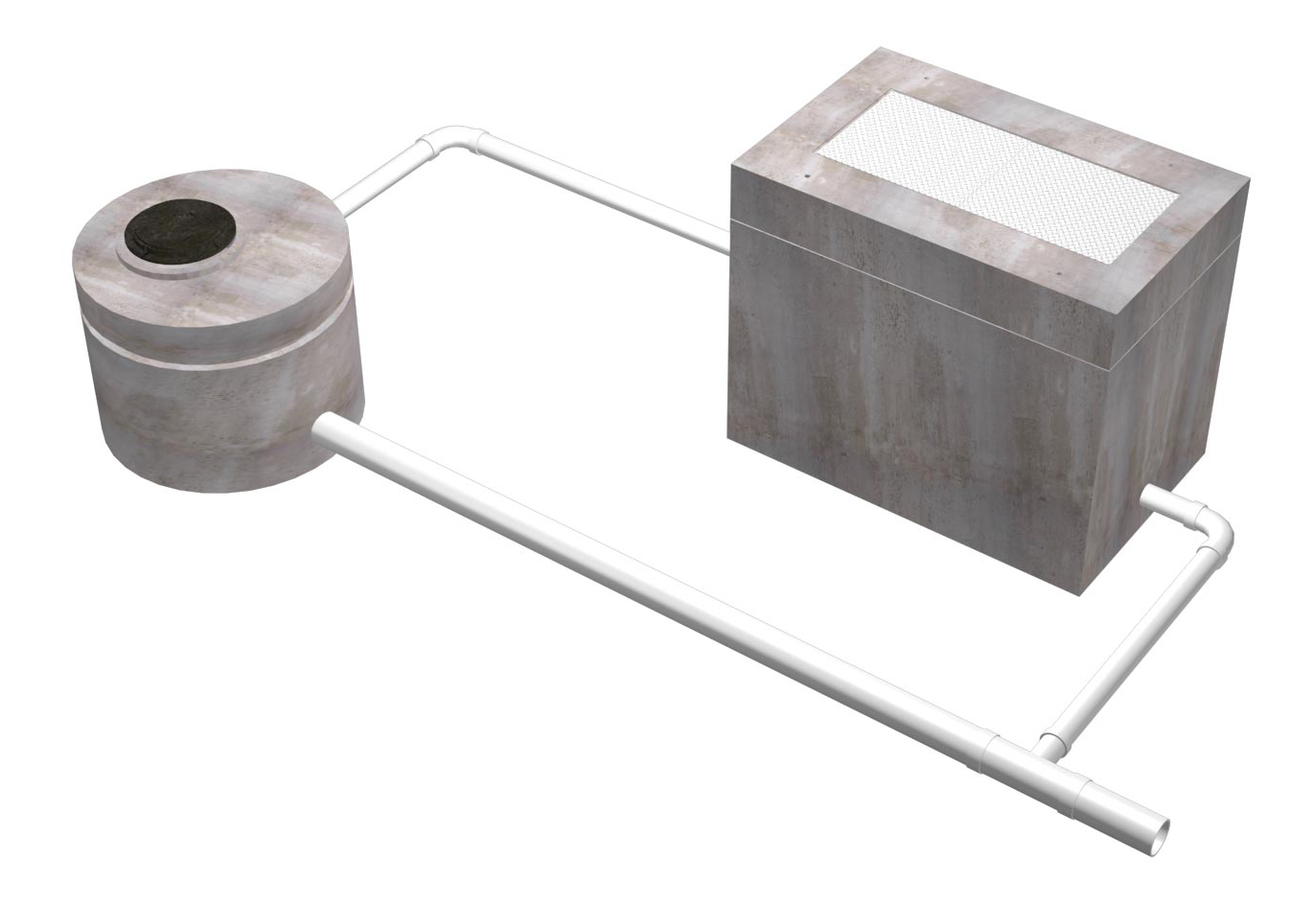

- OpTeaCup® can be paired with Grit Snail®, SpiraSnail®, or SpiraSnail® Compact dewatering

Downloads

Helpful Information

Product Information

- pdfOpTeaCup® Brochure

Media

Search Term:

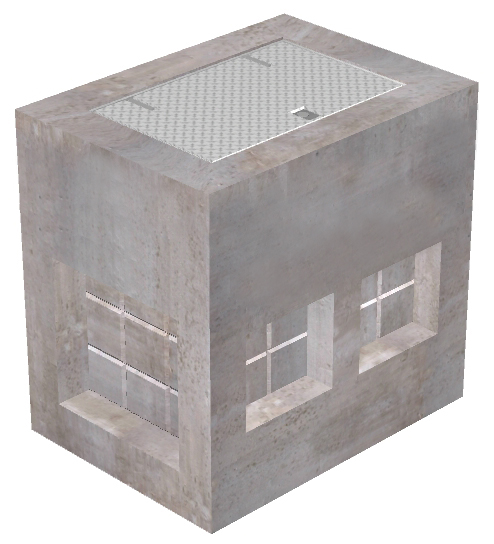

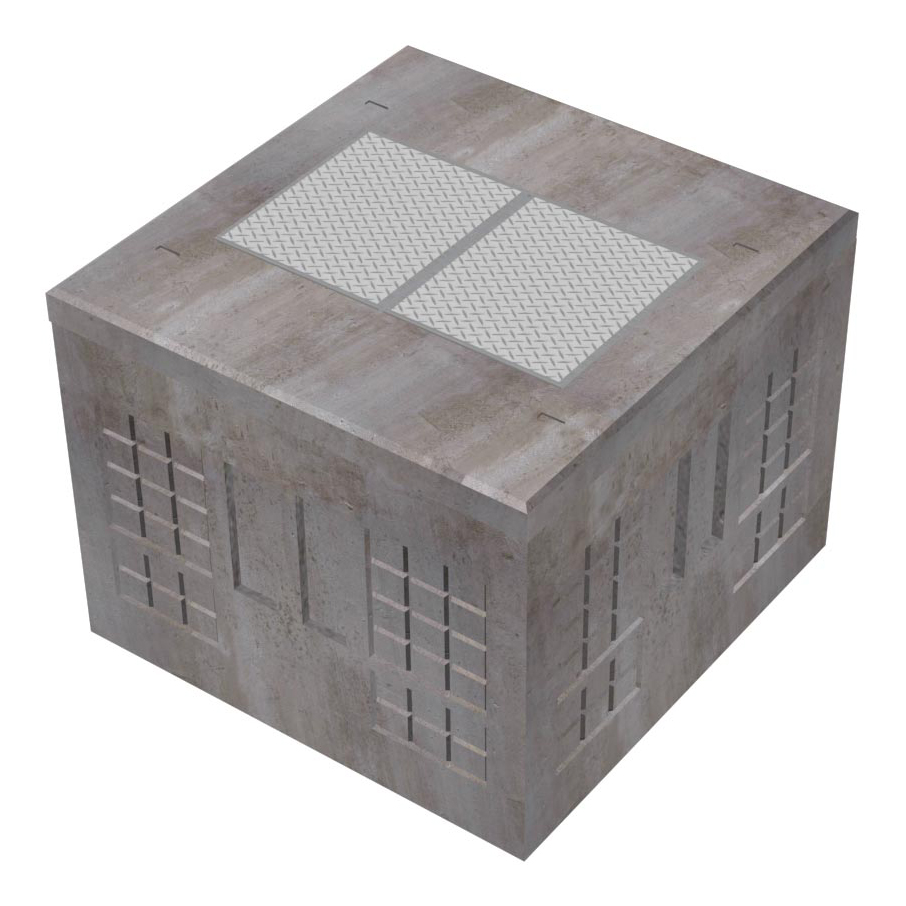

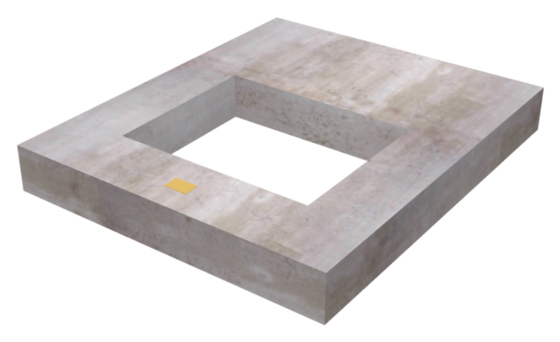

Concrete

High-Flow Bypass Manhole – Sizes Vary

Model: Hi-Flow Bypass Manhole - size varies

MFG Plant: Wilsonville, OR