March 25, 2025

The True Cost of EV Charging Installations: Price vs. Total Cost of Ownership

In my previous article, I delved on the differences in quality and control, speed of installation, labor resources and risk concerns between pre-cast and cast-in-place (CIP) construction methods. This article focuses on the vast difference between price and total cost of ownership (TCO) and why it is an important consideration when planning EV charging projects.

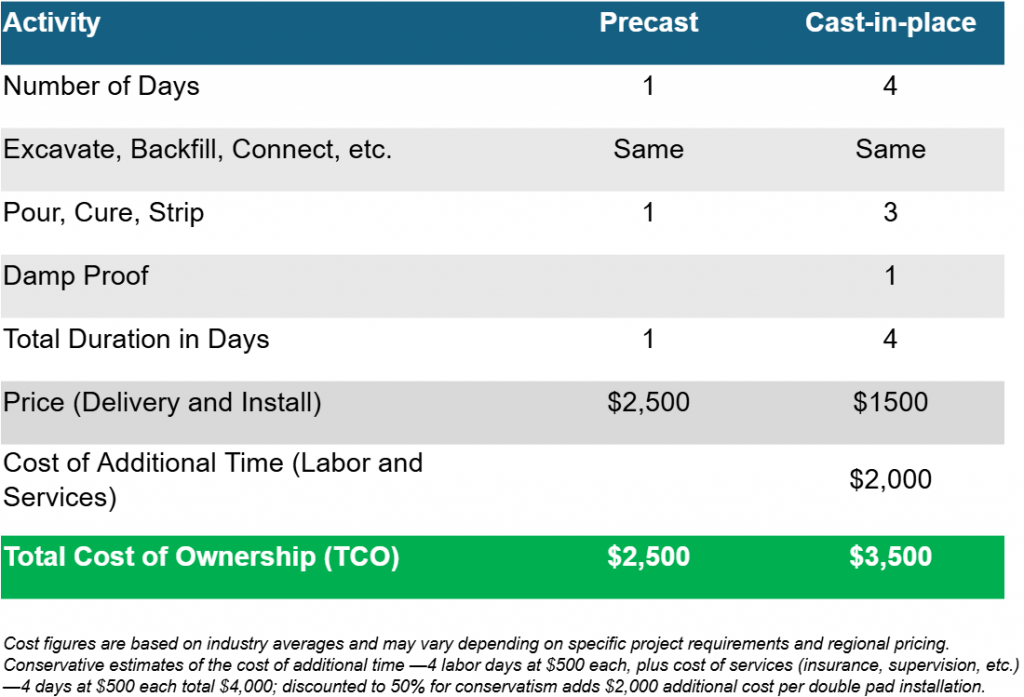

While precast solutions may come with a higher upfront cost, it often results in significant long-term savings. For example, while the material and installation cost for a precast underground structure might higher, the TCO of CIP may start much lower but increase when accounting for the additional time and labor required. The extra days of work required for CIP—due to pouring, curing, and finishing—adds not only labor costs but also general conditions costs (supervision, insurance, jobsite overhead, etc.).

We estimate an average of about 20 percent savings in a double pad installation:

Cost Comparison of Precast to Cast-in-Place EV Charging Double Pad Installation

In this example, even if CIP seems cheaper initially, the TCO ends up being higher due to extended project timelines and the added risk of delays or errors. Precast product’s faster installation helps save on additional time costs, and for contractors, every saved day equates to increased profitability.

Real-World Example: Cost Breakdown

Consider the above example of installing a double pad underground structure for an EV charging station. A precast unit would cost on average $1,500, with an additional $1,000 for crane services. Installation is completed in one day, including backfill, with no curing time required. On the other hand, CIP for the same structure, requiring labor for multiple pours, curing, and damp proofing, totals $1,500 for the materials alone, but the TCO increases once you factor in the extra time and labor.

Saving this extra time and labor means additional profit for the contractor and faster monetization for the site owner. When considering general condition costs, this savings could rise further. Precast offers a substantial reduction in the total cost compared to CIP, with potential higher savings depending on weather

Precast is the Better Choice

While CIP may offer advantages in certain cases—such as highly customized designs or challenging site conditions—precast solutions generally provides a better value for EV charging installations. The time savings, reduced labor, consistent quality, and lower TCO make precast the more efficient, cost-effective solution in most cases. When choosing between these two methods, contractors and specifiers should focus on the total cost of ownership rather than just the upfront price, recognizing that precast offers long-term savings that far outweigh its initial cost.

We’re here to help with your EV charging projects across the US. Visit EV Charging Infrastructure Solutions Center to access a wealth of resources and discover our extensive and adaptable product range.