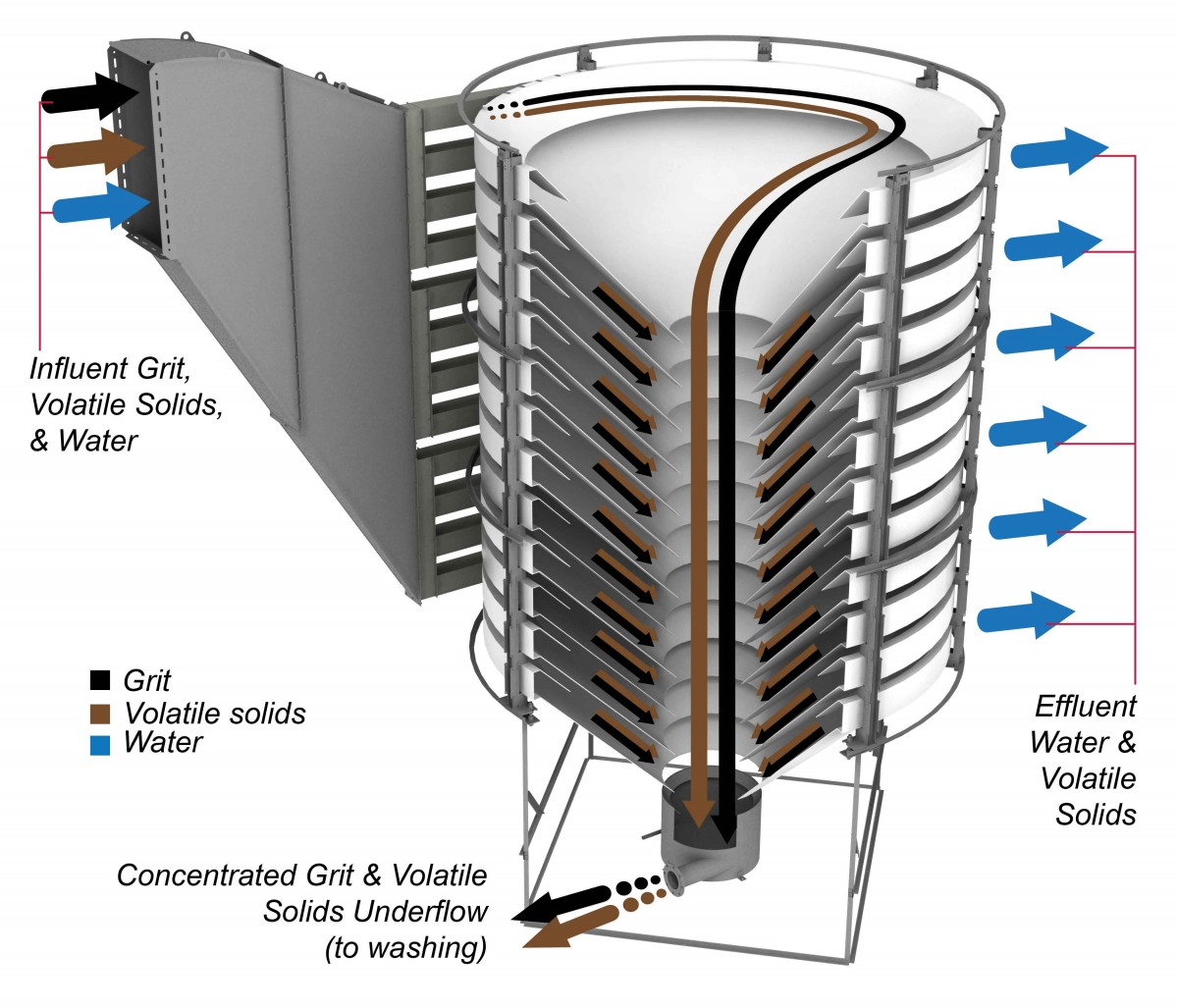

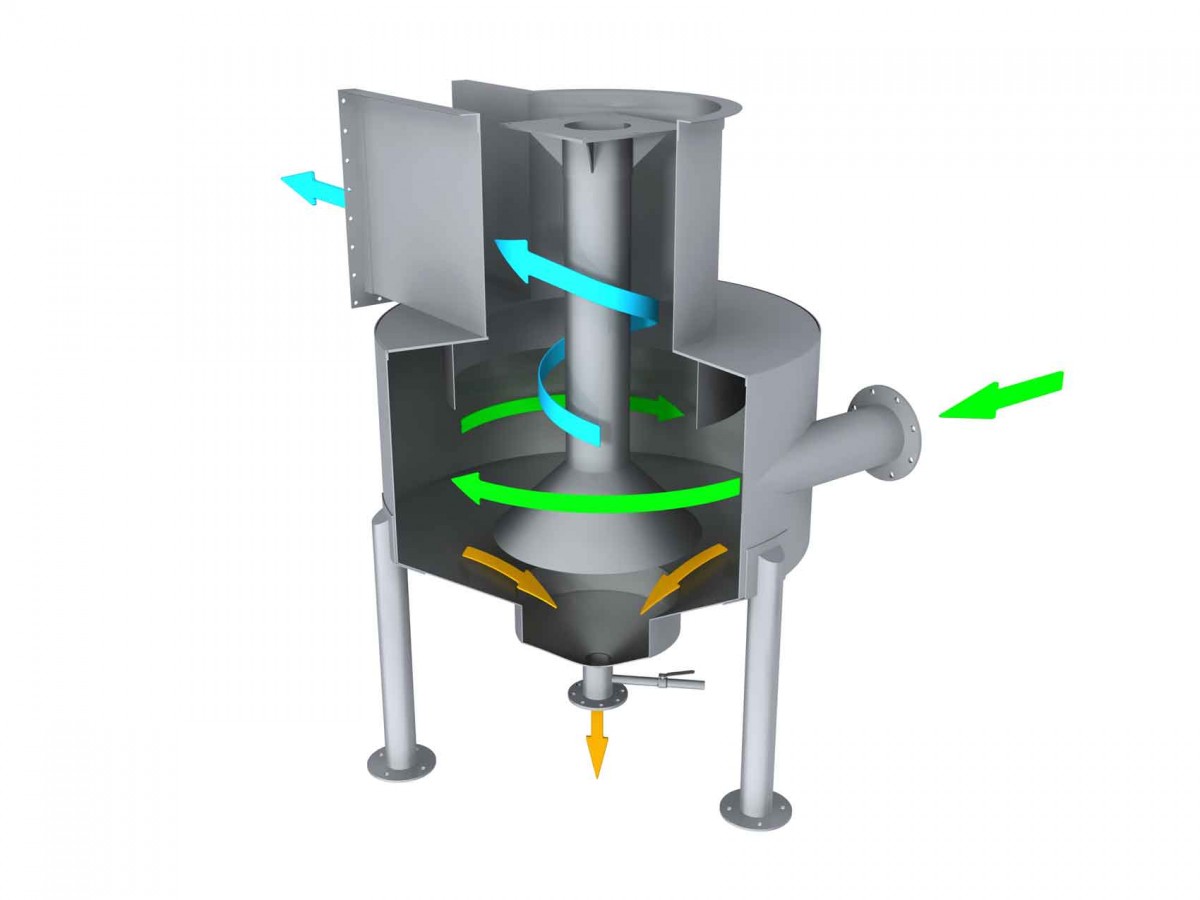

The HeadCell® modular stacked tray grit separator captures and retains 95% of all grit 75 micron and larger with minimal headloss, protecting downstream equipment and processes from abrasive wear and sedimentation.

With a small footprint, no electrical requirements, and no moving parts the HeadCell® delivers exceptional and economical solids removal for all sizes of wastewater treatment plants (WWTPs) – helping them to maintain treatment effectiveness and cut operation and maintenance costs.

The unique stacked tray design provides the surface area required for outstanding performance with a small footprint, enabling treatment capacity increases using existing space. Its durable design ensures long component life with minimal wear and grease build-up even under challenging operating conditions.

Enabling plants to meet stringent environmental requirements with less odors, the HeadCell® is the ultimate grit removal solution for new plants as well as representing a value-for-money retrofit option for grit removal upgrades. For new headworks grit control systems, the HeadCell® can be installed in a poured-in-place concrete basin above or at grade, with a footprint much smaller than conventional grit removal systems.

Applications

- Improved wastewater management

- New wastewater treatment plants

- Treatment plant retrofits

- Grit and / or sediment removal for potable water applications

- Industrial effluent degritting

Protect treatment equipment and processes from abrasive wear and sedimentation

The HeadCell® system is a force multiplier for the rest of the treatment plant: by removing grit and solids upstream in the process, critical and often sensitive downstream equipment is free to operate at full design capacity. Sedimentation and abrasion damage are drastically reduced, meaning that less energy and less maintenance is required.

The HeadCell® outperforms all other methods of grit separation, particularly when it comes to fine grit removal. Conventional and less capable systems can capture the larger particles, but it is fine grit – as small as 75 micron – which causes most problems for plants.

The HeadCell® system can be guaranteed to capture 95% of all grit 75 micron and larger.

Maximize wastewater treatment performance and free up plant space

Structured flow and low velocity operation extend product life significantly. The HeadCell® operates all-hydraulically, and requires less than a foot of headloss to operate, which saves your plant money.

Tray sizes and the number of trays can be modified to meet your site’s specific layout, flow, and performance requirements and can often be retrofitted into existing basins. Multiple units can be provided to accommodate any flow and / or any turndown ratio.

Double the treatment capacity in the same footprint as existing grit equipment

There’s nothing like the HeadCell® – the unique and proprietary structured flow configuration minimizes grease build-up, and its small footprint gives engineers the flexibility to incorporate future treatment capacity increases.

Your Project Deserves Expert Attention

Looking for a quote for your project?

While browsing our products, select “Add to Quote Generator” to quickly get an estimate for everything you need.