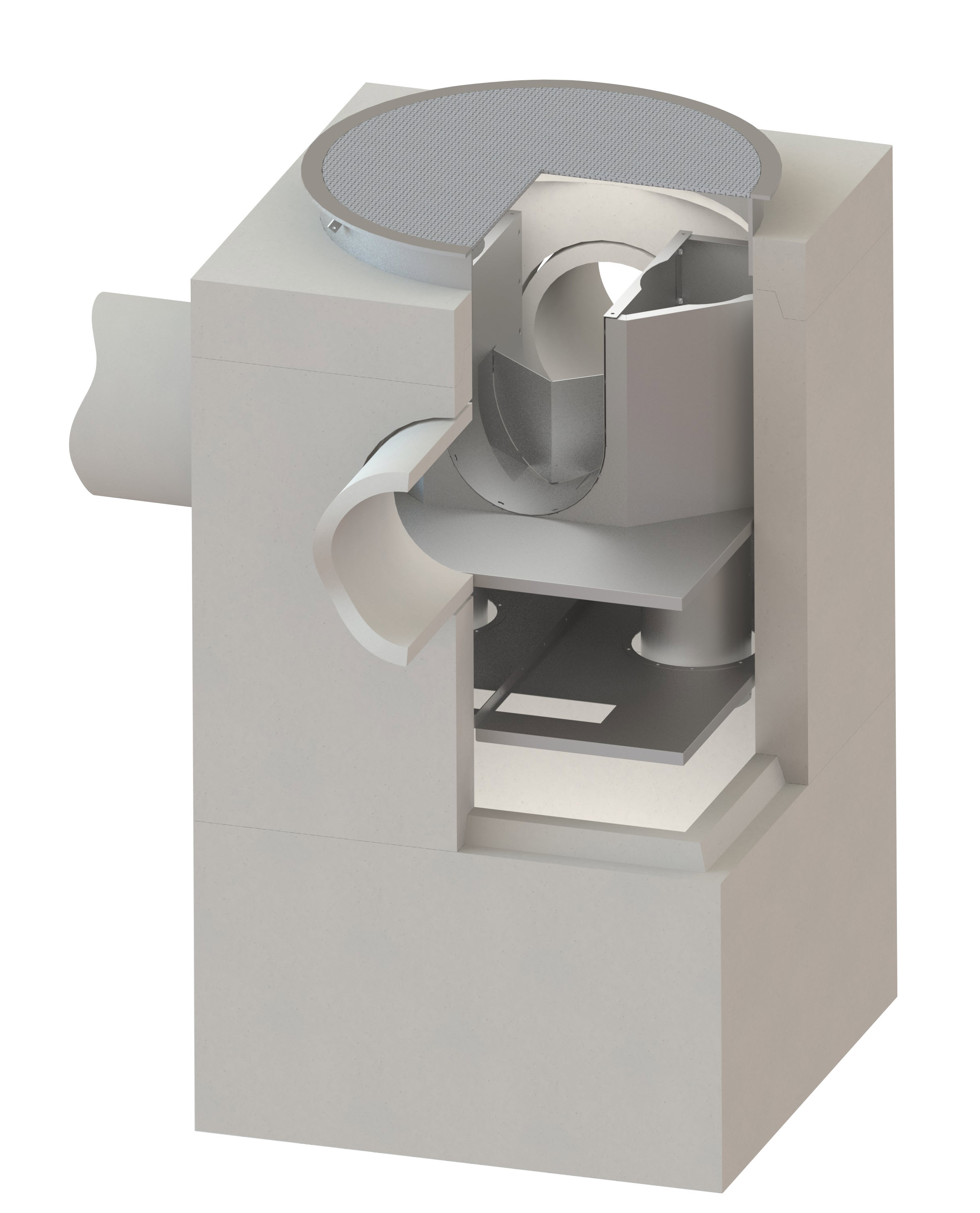

The DVS is a hydrodynamic separator that removes Total Suspended Solids (TSS), gross solids, trash and debris as well as petroleum hydrocarbons from storm water runoff. The DVS enhances pollutant removal by directing incoming flow to two vortex tubes that operate in parallel. The configuration of the vortex tubes and the extended flow path maximize residual time to increase the settling of solids. Sediment is collected in an isolated storage area while floating trash, debris and petroleum hydrocarbons are retained behind internal baffles. The DVS is available in multiple precast manhole and vault sizes with stainless steel internal components, and is sized to meet the water quality requirements of the specific site. The DVS contains an internal high-flow bypass weir system which diverts excess flows around the settling chamber, minimizing the risk of resuspension of pollutants, allowing for either online or offline configurations. The DVS offers an innovative and economic alternative for BMP implementation in new and retrofit applications where space is limited and effective storm water treatment is required. The DVS unit can be used to help meet TMDL requirements for removal of solids, trash, debris and petroleum hydrocarbons. The unit can also be a critical component of a comprehensive LID strategy to help increase the service life of infiltration, detention and retention systems as well as other storm water treatment BMPs. As with any storm water treatment system, the DVS requires regular maintenance to prolong the life of the system. Routine maintenance includes removal of accumulated pollutants through the vortex tubes with a vacuum truck. Frequency of maintenance depends on the conditions of the site and the performance of the system. Dual-Vortex Separator performance has been verified by the New Jersey Corporation for Advanced Technology (NJCAT), one of the most comprehensive, rigorous and recognized verification programs in the United States, and is approved by the New Jersey Department of Environmental Protection (NJDEP). The DVS is approved for online applications which can eliminate the need for a separate high-flow bypass structure upstream of the unit, thereby reducing project costs.

- Maintenance Accessible Design

- Economical Installation

- Multiple Access Options

- Online System Capability

- Durable Construction

- Proven Performance

- Treatment Train Configurations

- Open access to accumulated floatables and two access points to sediment storage area makes maintenance easy.

- Pre-packaged and provided in a compact manhole or small vault so installation is simple for the contractor.

- Multiple access options: manhole covers or optional hinged lids allow for site-specific customization.

- Internal high-flow bypass weir system provides for online configurations and eliminates the need for a separate bypass structure. DVS can also be used in offline configurations.

- Stainless steel components installed in a reinforced concrete structure.

- Third-party tested and certified.

- DVS can be used for pre-treatment and installed upstream of infiltration, detention and retention systems or other treatment BMPs.

Material: Concrete

Height: Variable

Width: Variable

Length: Variable

Downloads

Your Project Deserves Expert Attention

Looking for a quote for your project?

While browsing our products, select “Add to Quote Generator” to quickly get an estimate for everything you need.