January 5, 2026

Wastewater Treatment Plant Retrofit Improves Performance and Increases Capacity

Improving performance and increasing capacity for a wastewater treatment plant retrofit project

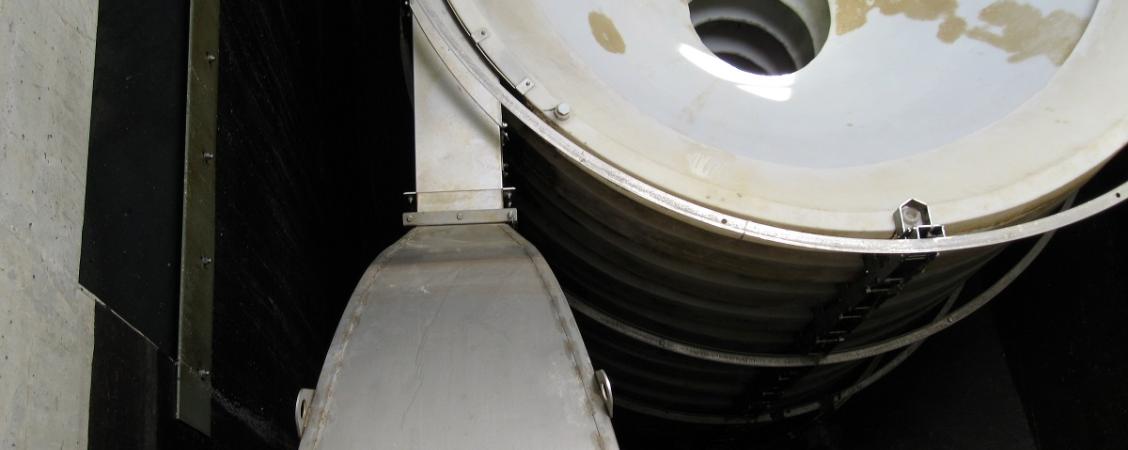

Retrofitting a HeadCell®, SlurryCup™, and Grit Snail® grit removal, washing, and dewatering system provided a significant performance improvement over Fox Lake WWTP’s aerated grit basin.

Background

The Fox Lake Wastewater Treatment Plant in Illinois faced a critical challenge with its aging aerated grit basin (AGB). The existing grit removal system was at the end of its useful life and needed to be replaced. The plant had two key requirements for the upgrade: the new equipment had to fit within the existing footprint, and it needed to eliminate grit deposition in the grit basin, which was extremely difficult to remove.

Fox Lake’s plant supervisor discovered the HeadCell® stacked tray grit removal system at the WEFTEC conference in Chicago. He was impressed by the stacked tray concept, which reminded him of lamella systems he had seen before. The design offered increased surface area for grit separation, which would significantly improve performance while staying within the space occupied by the old AGB.

The Problem

The existing aerated grit basin was underperforming. Prior to taking it out of service, a grit study was conducted to evaluate its efficiency. At design peak flow, the AGB should have been removing grit particles 225 microns and larger, and at lower flows, it should have captured even finer particles. However, testing during low flow conditions of only 824 gpm (52 L/s)—when the AGB should have removed all sand particles 50 microns and larger—revealed that the separator was only capturing 58% of incoming grit.

The downstream cyclone/screw washing and dewatering system performed even worse, retaining just 17% of the material delivered to it. This reduced the overall system efficiency to only 10% of influent grit captured. The plant needed a solution that could dramatically improve grit removal efficiency and prevent grit from depositing within the plant.

The Solution

To achieve the required performance, Fox Lake needed to double the surface area for settling grit. The stacked tray design of the HeadCell® allowed the plant to significantly increase surface area while remaining within the existing footprint. An isolation wall was poured to section off part of the old aeration basin, creating a dry pit for the grit pumps, while the remaining space housed the HeadCell® trays. A SlurryCup™ and Grit Snail® replaced the old cyclone/screw washing and dewatering system, providing advanced grit washing and dewatering capabilities.

The Outcome

Testing on a day with flows of 9.4 MGD (36 MLD) proved the new HeadCell® system to be 88% efficient overall. The HeadCell® grit collection chamber achieved 95% efficiency, and the SlurryCup™ and Grit Snail® washing and dewatering system retained 93% of the grit delivered to it. The retrofit provided a significant performance improvement over the previous aerated grit basin, ensuring better protection for downstream processes and improved plant reliability.

Learn more

- Discover the HeadCell®

- View our HeadCell® product brochure

- Learn more about the SlurryCup™

- Read the SlurryCup™ product brochure

- Learn more about the Grit Snail®

- View the Grit Snail® product brochure