September 21, 2018

CELL TOWER FOUNDATION INSTALLED IN 6 HOURS USING PRECAST CELLBLOCKS® SYSTEM

HIGHLIGHTS

Project Location: Contact, Nevada

Owner: Verizon Wireless

Construction Manager: Complete Wireless Consulting

Design Engineer: PJ Ford Engineers

Oldcastle Product(s):

- Precast Concrete Manufacturer

- Pleasanton, California

- Precast Concrete CELL BLOCKS® Foundation

- 25 CELL BLOCKS Foundation

Telecommunications Site

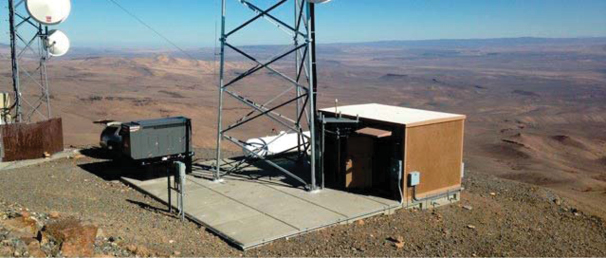

- 81 Foot tall self supporting tower with 15-feet face width.

- 125.3 Inch diameter microwave dish at 59-feet AGL with ice shield.

- 103.4 Inch diameter microwave dish at 29-feet AGL with ice shield.

- Three wireless sectors with three antennas each at 77’ AGL.

- 11’-6” X 16’-11” equipment shelter.

- 1000 Gallon propane tank.

- 60 KW standby propane generator.

Complete Wireless Consulting Inc. was tasked by a major telecom carrier to secure a lease and entitlements for the installation of a wireless cell tower on Ellen D. Mountain near Contact, Nevada. At an elevation of 8614 AMSL, the site was located in the northeast corner of Nevada on land overseen by the Bureau of Land Management (BLM). The proposed lease area for the major telecom carrier was 35’ x 35’. All parties desired a dependable solution that required a minimal amount of equipment and labor resources.

The BLM would only permit a foundation that minimized disruption to the existing ground and allowed for future site removal with less impact on the land. The precast concrete, post tensioned, Cell Blocks patented foundation system met this criteria and was selected for this site to support the telcom equipment conditions and, in turn, minimized the safety concerns about unknown underground hazards at the auto repair garage. The business interruption was minimal.

Cell Blocks are an engineered foundation system made from individual precast concrete blocks that are assembled in various configurations and post-tensioned providing a foundation for a monopole and equipment.

THE DESIGN

Designed by engineering firm PJ Ford Engineers, 25 Oldcastle Infrastructure CELL BLOCKS were manufactured to create the 35-foot by 35-foot foundation for the major telecom carrier’s wireless cell tower, microwave dishes, antennas, equipment shelter and generator.

THE SOLUTION

Structural drawings and calculations were first provided to the carrier’s construction manager, Complete Wireless Consulting, and the precast foundation blocks were then fabricated at the precast manufacturing facility near Pleasanton, CA. Anchor bolts and templates were provided to the precast facility by the self-supporting tower fabricator. The post tension GR 150 galvanized steel bars, hex nuts and plates were ordered from DSI America, Inc.

Special equipment (straight truck with 4 drive axles) was used to expedite delivery of the blocks to the mountain top.

With the precast blocks fabricated, the post tension steel ready, the shelter set to ship and the tower fabrication completed, the installation date was set.

On that day, a crane was set up and the crew placed twenty-five Cell Blocks, within 6 hours, atop the prepared granular base material. The minimum allowable soil bearing requirement was 1500 psf. The post tension bars, hex nuts and plates were immediately inserted to begin the hydraulic post tensioning process which took two hours. Oldcastle Infrastructure provided a certified hydraulic pump and 100 ton jack to post tension the steel bars to the specified tension force.

The shelter, generator, tank and tower were set immediately after the blocks were post tensioned.

The advantage of the Cell Block foundation was that, once post tensioned, the foundation was instantly full strength. Oldcastle Infrastructure provided an experienced representative, on-site, for the duration of the block installation and post tensioning process. The representative was able to ensure proper construction and assure the quality of the completed foundation.

One crane set the blocks, shelter, generator, tank and the tower on a foundation that was immediately full strength.

COMPLETION

Complete Wireless Consulting was then provided with a final certification package that included: certification of all materials, structural design permit drawings, calculations and jacking forces. The foundation was designed to support loads per ANSI/TIA 222- Rev G, Structure Class II, Exposure Category C, Topographic Category 3 and wind velocity of 120 MPH.

Using post tensioned precast concrete CELL BLOCKS for this wireless facility helped to ensure the installation was extremely predictable and required a minimal amount of resources. A one-day foundation installation process meant the entire site could be built in less than one week.