Oldcastle Infrastructure has entered a commercial agreement with VODA.ai, a global company focused on using AI technology to quickly and accurately identify areas in underground clean water systems which are at high risk of failure.

The partnership adds proven AI technology for the data analysis and predictive reporting of water system failures to Oldcastle Infrastructure’s market-leading CivilSense™ asset management solution, making it the first to deliver both predictive and real-time leak detection and risk analysis to water utilities.

It is estimated that around 2.7 trillion gallons of drinking water are lost annually in the US due to leaks and main breaks, which equates to a staggering $6.4 billion in public and private revenue losses. The primary cause of these losses is aging infrastructure.

CivilSense™ supports utilities with risk mitigation and proactive management of water systems and is the only platform and service that removes the uncertainty of main breaks and water system failures, coupled with the pinpoint accuracy of identifying existing leak locations.

The predictive technology accurately assesses and forecasts areas of high failure risk, while the leak detection service uses strategically deployed acoustic sensors in the identified risk areas to locate and analyze the size of water leaks.

“Our utility customers told us they struggle to mitigate the risk of water main breaks and subsequent loss of service to customers because they don’t have the technology or resources to effectively predict where the next potential break will occur. The partnership with VODA.ai gives CivilSense™ this expanded capability. This means accurately identifying where main breaks are most likely to occur, then using leak detection sensors to determine exactly where, and how large, leaks are now,” explains Jeff Petrosky, Senior Vice President, Strategy and Marketing at Oldcastle Infrastructure.

Petrosky adds, “CivilSense™ gives utilities the ability to make data-driven decisions and allocate labor and budget effectively. This means no digging where there are no leaks, and prioritizing leaks where the greatest water loss is occurring.”

VODA.ai also highlights the importance of the relationship in support of comprehensive water asset management. “We are thrilled to partner with Oldcastle Infrastructure and provide our powerful, AI-driven predictive analytics as a part of the CivilSense™ platform. For us, this partnership means expanding our reach to more communities, helping to prevent water loss, and making a greater impact on sustainable water management,” notes Cory Sides, SVP Sales, VODA.ai.

The predictive technology gives utilities, both public and private, the ability to see their own Geographic Information System (GIS) data across multiple dimensions, such as likelihood of failure, consequence of failure, and business risk exposure.

This data visualization allows for improved protection of critical infrastructure and prioritization while affording efficient budget and asset management planning.

CivilSense™ gives utilities the ability to make data-driven decisions and allocate labor and budget effectively. This means no digging where there are no leaks, and prioritizing leaks where the greatest water loss is occurring.

This partnership is part of Oldcastle Infrastructure’s long-term commitment to the growth and expansion of the CivilSense™ asset management platform.

Jason Jackson, President of Oldcastle Infrastructure, says, “The commercial partnership with VODA.ai speaks to our commitment to help solve our nation’s biggest infrastructure challenges. Water is vital for people, manufacturing, communities, and the planet. It is a finite resource we cannot afford to mismanage. I am proud to add this partnership as part of our expanded offering of CivilSense™. We are making a difference in our communities by helping our utility customers solve significant water challenges because, with CivilSense™, we are making the invisible visible.”

About CRH

CRH plc (NYSE: CRH) is the leading provider of building materials solutions that build, connect and improve our world. Employing 80,000 people at over 3,800 operating locations in 28 countries, CRH has market leadership positions in North America and Europe. As the essential partner for transportation and critical infrastructure projects, complex non-residential construction and outdoor living solutions, CRH’s unique offering of materials, products and value-added services helps to deliver a more resilient and sustainable built environment. The company is ranked among sector leaders by Environmental, Social and Governance (ESG) rating agencies. A Fortune Global 500 company, CRH’s shares are listed on the NYSE and LSE. For more information visit crh.com

About VODA.ai

VODA.ai is a Boston-based SaaS company that uses artificial intelligence to enhance decision-making for water utilities. Its platform provides detailed insights into the condition and risk of water and wastewater systems, enabling utilities to prioritize repairs and investments with confidence. Learn more at voda.ai

New York – [October 2, 2024] – CRH (NYSE: CRH), the leading provider of building materials solutions, is supporting the development of pioneering water management technology through an investment in FIDO AI, the artificial intelligence (AI) leak detection software company. FIDO AI’s technology is helping to improve water resilience by curating water data insights to minimise water leakage, reduce downtime and preserve valuable water resources.

Led by CRH’s venture capital unit, the Series B investment expands CRH’s water management capabilities into the smart water market. It builds on CRH’s existing relationship with FIDO AI through Oldcastle Infrastructure, our [market leading] water infrastructure solutions business in North America.

As well as providing water management insights and prioritisation in real time to utilities and municipalities, FIDO AI’s technology is increasingly being used in the development of corporate water stewardship programmes to address global water challenges.

Commenting, Eduardo Gomez, Head of CRH Ventures, said: “This investment underscores our commitment to scaling the most promising and cutting-edge innovative technologies. FIDO AI’s technology aligns seamlessly with CRH’s focus on developing innovative and sustainable solutions for the built environment. We look forward to strengthening our existing partnership and to driving transformative innovation and impact in water management.”

(Atlanta, GA) – Oldcastle Infrastructure, a CRH Company, and a leader in innovative infrastructure solutions, today announced its entry into the smart water market through a strategic partnership with FIDO Tech, a UK-based Artificial Intelligence (AI) and technology solutions provider, to deliver unparalleled leak detection and broader water management and conservation solutions in the United States.

The United States loses roughly two trillion gallons of treated drinking water annually, costing municipalities, government agencies and water districts an estimated $7.5 billion1. Oldcastle Infrastructure’s comprehensive suite of smart water solutions, powered by FIDO Tech’s advanced technologies with actionable AI at the core, will provide municipalities, water utilities and industrial clients with real-time monitoring, leak detection and predictive analytics to address treated drinking water losses.

Leveraging its national footprint, Oldcastle Infrastructure will facilitate and accelerate the rollout of FIDO Tech’s AI-led non-revenue water (NRW)2 detection service across the US market. This will allow more US utilities to benefit from FIDO Tech’s current leakage reduction levels of more than 50%.

“Solving non-revenue water losses is a quantifiable and guaranteed way to improve water availability and security,” said Victoria Edwards, Co-Founder & CEO, FIDO Tech.

“Leading the AI revolution in water, FIDO Tech is delighted to partner with Oldcastle Infrastructure for their proven expertise and breadth of water infrastructure solutions to deliver smart water services across the North American market.”

Leveraging real-time data, municipalities, water utilities and industrial customers will be able to optimize operations and prioritize leaks ahead of a catastrophic system failure, reducing repair costs and downtime. The partnership between Oldcastle Infrastructure and FIDO Tech reinforces the shared commitment of both companies to sustainability, resilience, and technological innovation. By harnessing the power of their combined expertise, Oldcastle Infrastructure and FIDO Tech aim to transform water management practices and contribute to building a more sustainable future.

About Oldcastle Infrastructure

Oldcastle Infrastructure, A CRH Company, is the leading provider of infrastructure solutions to several North American market sectors, including Water, Communications, Energy, and Transportation. For more information, visit www.oldcastleinfrastructure.com.

About CRH

CRH (LSE: CRH, ISE: CRG, NYSE: CRH) is the leading provider of building materials solutions that build, connect and improve our world. Employing c.75,800 people at c.3,160 operating locations in 29 countries, CRH has market leadership positions in both North America and in Europe. As the essential partner for road and critical utility infrastructure, commercial building projects and outdoor living solutions, CRH’s unique offering of materials, products and value-added services helps to deliver a more resilient and sustainable built environment. A Fortune Global 500 company, CRH is a constituent member of the FTSE 100 Index, the EURO STOXX 50 Index, the ISEQ 20 and the Dow Jones Sustainability Index (DJSI) Europe. The company is ranked among sector leaders by Environmental, Social and Governance (ESG) rating agencies. CRH’s American Depositary Shares are listed on the NYSE. For more information visit www.crh.com.

About FIDO Tech

FIDO is a global technology company using deep learning to find the water leaks that matter. Its AI is the only technology that uploads any files from any sensor device, analyses them instantly, and ranks by size, to more than 92% accuracy. FIDO AI is the only data-as-a-service (DaaS) end-to-end leak detection solution which identifies leaks and the size of leaks to hit water losses hard. Now we can locate them exactly too. Our cutting-edge AI was trained on verified leak data to deliver instant super-accurate results on any water network. Nothing beats FIDO at finding the biggest leaks the first time.

1 ASCE Infrastructure Report Card – Drinking Water: https://infrastructurereportcard.org/wp-content/uploads/2017/01/Drinking-Water-2021.pdf

2 Non-Revenue Water – water that has been produced and is “lost” before it reaches the customer.

Oldcastle infrastructure™, A CRH Company has today announced that it has acquired Hydro International® (“Hydro”) from funds advised by Agilitas Private Equity LLP. Hydro is a leading provider of stormwater products, wastewater treatment products, wastewater services, and data solutions in North America and Europe. The company works directly with municipal, commercial and industrial customers to improve the way that water is processed, treated and managed. Headquartered in Clevedon, UK, and with a sales presence in 19 countries, it has over 40 years of experience and a reputation for engineering excellence and industry-leading product performance.

The strategic addition of Hydro International to Oldcastle Infrastructure’s water management offering further enables the company to fulfill its vision to be a leading provider of solutions in the circular water economy. Factors including increased water regulation, aging infrastructure and increased government funding are paving the way for Oldcastle Infrastructure, to address the critical water treatment and management needs of global communities. Acquiring Hydro further enhances its water treatment solutions offering, bringing product breadth, market expertise, and well-developed R&D capabilities.

“We are continually looking for ways to create value for our customers through innovation and advanced technology. Bringing Hydro into our infrastructure solutions business directly aligns with that approach and further advances our water market strategy,” stated Jason Jackson, President, CRH Infrastructure Products. “As one of the most respected players in the North American and UK stormwater and wastewater markets, Hydro brings extensive market knowledge and strong specification positions that will drive growth for us both in Europe and North America.”

“The opportunities for synergy between Oldcastle Infrastructure and Hydro are tremendous,” said Paul Cleaver, CEO, Hydro International. “Hydro has a legacy of driving innovation and accelerating growth through new products and services development. Combining Hydro’s product expertise with Oldcastle Infrastructure’s commercial platform enables our teams to uniquely solve ever-expanding problems for our customers in the water market.”

Visit Hydro International at https://www.hydro-int.com/en

About Oldcastle Infrastructure

Oldcastle Infrastructure, A CRH Company, is the leading provider of infrastructure solutions to several North American market sectors, including Water, Communications, Energy, and Transportation. For more information, visit www.oldcastleinfrastructure.com.

About CRH

CRH (LSE: CRH, ISE: CRG, NYSE: CRH) is the leading provider of building materials solutions that build, connect and improve our world. Employing c.75,800 people at c.3,160 operating locations in 29 countries, CRH has market leadership positions in both North America and in Europe. As the essential partner for road and critical utility infrastructure, commercial building projects and outdoor living solutions, CRH’s unique offering of materials, products and value-added services helps to deliver a more resilient and sustainable built environment. A Fortune 500 company, CRH is a constituent member of the FTSE 100 Index, the EURO STOXX 50 Index, the ISEQ 20 and the Dow Jones Sustainability Index (DJSI) Europe. The company is ranked among sector leaders by Environmental, Social and Governance (ESG) rating agencies. CRH’s American Depositary Shares are listed on the NYSE. For more information visit: www.crh.com.

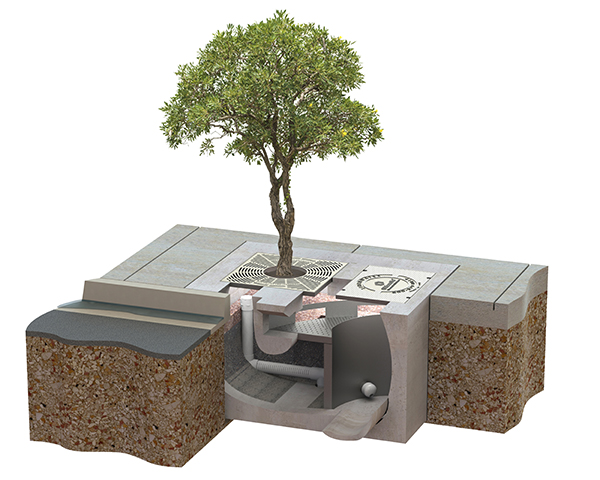

ATLANTA, Ga. (November 7, 2018) – Oldcastle Infrastructure is pleased to report that the BioPod Biofilter System with StormMix™ Media has been reviewed and approved by the Virginia Department of Environmental Quality. The BioPod is approved and listed on the Virginia BMP Clearinghouse with a 50% total phosphorus removal efficiency, the highest available rating. The approval was secured based on our field data set from the state of Washington, and the General Use Level Designation (GULD) received there.

BioPod systems utilize an advanced biofiltration design for filtration, sorption and biological uptake to remove Total Suspended Solids (TSS), dissolved metals, nutrients, gross solids, trash and debris as well as petroleum hydrocarbons from stormwater runoff. BioPod systems use StormMix media, an engineered high-flow rate media to remove stormwater pollutants.

The BioPod system offers an optional integrated high-flow bypass that eliminates the need for a separate bypass structure, reducing costs and simplifying the design.

Offering flexibility of design and construction for your storm drain system, the BioPod system comes as an all in-one, single-piece unit composed of durable precast concrete for ease of installation and a long service life.

The BioPod will soon be included on the Virginia Best Management Practices (BMP) Clearinghouse website: https://www.swbmp.vwrrc.vt.edu/.

“Now that the BioPod has received approval, designers in Virginia will have a state of the art, engineered, high flow rate bioretention option for stormwater treatment and green infrastructure solutions,” said Joanna Ogintz, Oldcastle Infrastructure Regulatory Engineer.

About Oldcastle Infrastructure

Oldcastle Infrastructure, A CRH Company, is the leading provider of building materials, products and services for infrastructure projects to several market sectors nationwide, including: Building Structures, Communications, Energy, Transportation and Water.

For more information, visit www.oldcastleinfrastructure.com.

About CRH in North America

CRH is the leading supplier of building materials and products for residential, non-residential and infrastructure construction projects across the United States and Canada. CRH’s Americas Materials Division supplies aggregates, asphalt, ready mixed concrete, cement, and paving and construction services. CRH’s Americas Products Division supplies a broad range of value-added building products through its three primary businesses: Oldcastle Architectural, Oldcastle Infrastructure and Oldcastle BuildingEnvelope®.

For more information visit www.crhamericas.com.

Download Full Press Release