Decades of Scientific Expertise, Now at a Much Larger Scale.

Hydro International is now a part of Oldcastle Infrastructure! Hydro International has provided cutting-edge water treatment technologies to the water & wastewater community for over 45 years and our installation base continues to grow in the wastewater market. Today, we have over 1,300 HeadCell® and Grit King® systems installed throughout North America. Many of these installations have been in continuous operation for over 20 years.

Hydro International’s rigorous application of cutting-edge science to continually improve products has been taken to the next level as part of Oldcastle Infrastructure. With significantly expanded hydraulics laboratory facilities and a much larger team, we have retained that commitment to quality and expanded the scope and scale of our operations in the wastewater market.

Selecting a Grit Management Solution

Every site is different, and engineers, architects, and contractors must balance a range of factors to meet site-specific requirements and local regulations. The most important aspects to consider when designing and building a grit-management system are:

Performance

Proven in-field results and independently tested for industry-leading grit removal performance.

Footprint

Compact designs free up valuable WWTP space for other treatment processes and future expansion.

Flexibility

Easily integrates into existing infrastructure—minimizing pipe rerouting, structure modifications, and channel rebuilds.

Utility Costs

Optimized head‐loss requirements and energy efficiency reduce ongoing electricity and water expenses.

Manufacturer Support

End-to-end grit process expertise and responsive service ensure your system runs reliably 24/7.

Reliability & Longevity

Durable, minimal-moving-parts designs extend equipment life and lower maintenance burdens over decades.

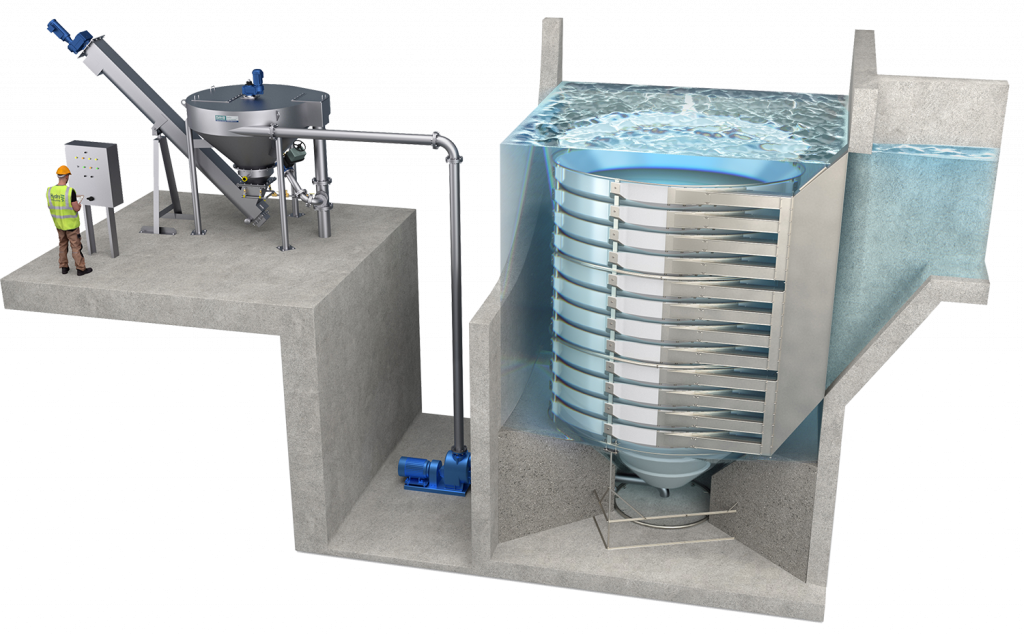

Grit Removal & Pretreatment Systems

Protect downstream equipment with our end-to-end grit removal and pretreatment portfolio, from inline sludge screening and degritting to headworks grit separation, washing, classification, and dewatering. Our technologies help you minimize and optimize hydraulics and meet effluent standards.

Grit Washing / Classification

Grit Dewatering

Combined Washing & Dewatering

Compact Grit Systems

FAQ

What is Grit Removal?

Grit removal is the process used to remove sand, silt and grit from water.

Grit (and sand) removal is often found in the headworks or inlet works of wastewater treatment plants (WWTPs). It can also be used to remove sand from river water intakes prior to potable processing, to strip out fine abrasives, or to extract grit entrained in sludge.

What is Wastewater Grit?

Conventional grit removal equipment is designed based on the mistaken assumption that all grit particles are perfect spheres of silica sand greater than 212 microns in diameter and with a specific gravity of 2.65.

Why Remove Grit?

Sand in treatment plants reduces process capacity and increases maintenance costs.

In WWTPs, grit and other solids such as sugar sands and silt are costly components of both process water and wastewater—clogging systems, cutting efficiencies, and abrading equipment, which leads to more cleaning, maintenance, and repair.

Because many systems assume ideal particle behavior, they may only remove 30–50 % of total suspended solids (TSS). The rest passes downstream, abrading critical systems and gradually diminishing overall plant performance—often without operators even realizing what they’re missing.

Effective grit removal strips out abrasive solids before they can erode equipment or deposit throughout the plant.

What is the Cost of Grit?

Grit that passes through a WWTP or industrial process facility has a real cost. If not removed, it compromises downstream processes via abrasion of mechanical equipment and through accumulation in channels and basins.

Real-World Conditions

While laboratory testing is useful as an indicator of performance, it should never be taken in isolation. After all, WWTPs and industrial facilities operate in the real world, not in a lab.

Which Water Solutions Align With Your Project?

Get more information by filling out the quick form below.

Looking for a quote for your project?

While browsing our products, select “Add to Quote Generator” to quickly get an estimate for everything you need.

We use cookies to offer you a better browsing experience, analyze site traffic, personalize content, and serve targeted advertisements. Read about how we use cookies and how you can control them by visiting our Cookie Statement. If you continue to use this site, you consent to the use of cookies.