As part of UC San Diego Health’s $3 billion Hillcrest Medical Campus expansion, the organization initiated major improvements to Bachman Place, a 0.6‑mile connector road linking Hillcrest and Mission Valley in San Diego, CA. The road serves dual roles: a public access route and a critical entryway to UC San Diego Health facilities.

Upgrades included widening the roadway to 43 feet, adding dedicated bike lanes, incorporating a 5‑foot pedestrian sidewalk, improving lighting and signage, upgrading utilities, and enhancing travel safety for the steep 9-11% grade corridor.

Given the roadway’s unique ownership status and its importance to both commuters and hospital operations, the improvements required high‑performance, long‑lasting infrastructure solutions.

Challenge

The project team faced significant site constraints due to the roadway running through narrow canyon terrain. Designers had very limited locations available for stormwater treatment and utility placement, forcing the biofiltration system to be installed beneath a pedestrian walkway-an unconventional configuration requiring careful engineering.

Since UC San Diego Health would be solely responsible for roadway maintenance, the organization needed low‑maintenance, robust stormwater BMPs that would minimize lane closures and reduce long‑term operational costs.

Additionally, the City of San Diego rarely approves non‑vegetated proprietary biofiltration systems, creating regulatory hurdles. The steep grade, major utility relocation, environmental review delays, and the need for strong third‑party performance validation further complicated the design and approval process.

Solution

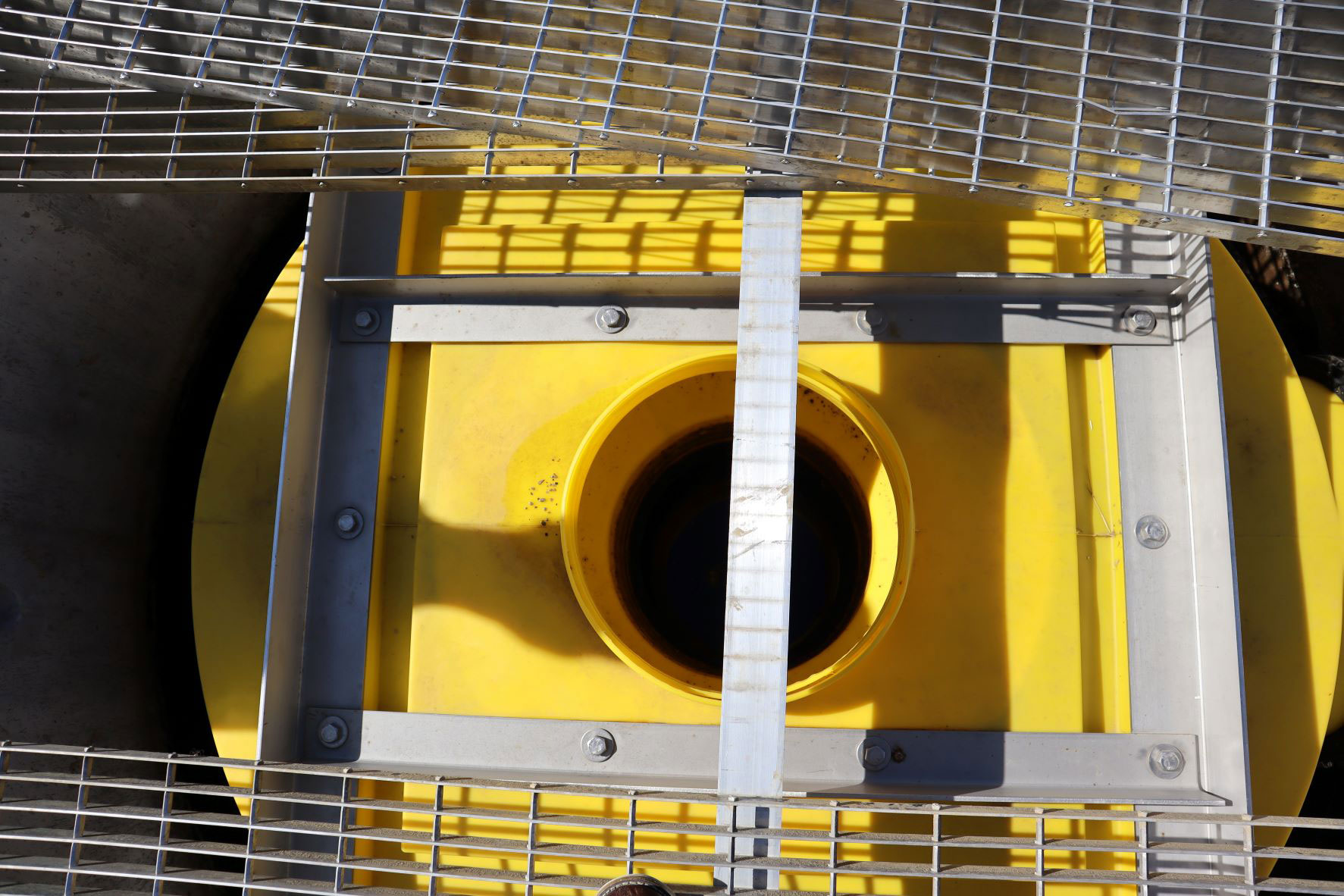

Oldcastle Infrastructure partnered with the engineering team early in the design process to provide specialized stormwater and utility solutions tailored to the project’s space, slope, and ownership challenges. The BioPod™ Biofiltration System was selected for its compact footprint, durable non‑vegetated media option, and reliable third‑party maintenance interval data, making it ideal for installation beneath pedestrian infrastructure while still meeting stringent water quality requirements.

Oldcastle Infrastructure also supplied custom precast components to support utility relocation and structural needs along the steep canyon corridor. Through a comprehensive preconstruction and technical support process, Oldcastle Infrastructure helped model hydraulic performance, address loading concerns, streamline installation sequencing, and provide documentation that enabled the City of San Diego to approve two non‑vegetated proprietary systems-an uncommon achievement. This combination of expertise and product capability delivered a tailored stormwater strategy that met UCSD’s long‑term operational priorities.

Sustainability Impact

The BioPod systems contributed to a more sustainable roadway by delivering reliable stormwater treatment within a constrained environment where traditional vegetated BMPs were not feasible. Their low‑maintenance design reduces long‑term resource consumption and minimizes disruption to vehicle flow, lowering the environmental impact associated with frequent maintenance closures.

The precast components provided by Oldcastle Infrastructure supported efficient installation, reduced onsite construction emissions, and created durable, long‑life infrastructure aligned with UCSD’s goals for future‑ready campus development. By enabling effective pollutant removal on a steep, highly trafficked corridor, Oldcastle Infrastructure’s sustainable solutions helped enhance environmental protection for the surrounding canyon ecosystem.

Overall Impact

Completed in June 2025, the project delivered a safer, wider, and more efficient roadway equipped to support future medical campus growth. The enhancements improved mobility for drivers, cyclists, and pedestrians while significantly reducing commute times-estimated by UCSD to save drivers up to 30 minutes.

Oldcastle Infrastructure’s stormwater and utility solutions played a critical role in resolving space, maintenance, and regulatory challenges, reducing long‑term ownership costs, and ensuring the roadway performs reliably under demanding site conditions. The approval and successful deployment of non‑vegetated proprietary systems also set a precedent for innovative stormwater management in dense, topographically complex areas.

Conclusion

The UC San Diego Hillcrest North Access Road project demonstrates how early collaboration and engineered precast solutions can overcome significant geographic and regulatory constraints. Oldcastle Infrastructure’s BioPod solution and precast components enabled the project team to deliver a high-performing, low‑maintenance, and environmentally responsible roadway that supports both public circulation and hospital operations.

This project highlights the importance of selecting adaptable, high‑performance infrastructure solutions, especially when working within narrow, highly regulated, and environmentally sensitive corridors. Oldcastle Infrastructure’s involvement ensured a successful outcome and reinforced its role as a trusted partner in complex, sustainability‑driven infrastructure projects.

The City of Melbourne, Florida, has been working for nearly a decade to restore the Indian River Lagoon, one of the most ecologically significant waterways in the state.

Since 2015, Melbourne has installed baffle boxes as part of its stormwater infrastructure improvement program.

These structures intercept pollutants carried by stormwater runoff before they enter the lagoon, helping protect water quality and marine life. The initiative was funded by a voter-approved 0.5 cent sales tax dedicated to lagoon restoration projects.

Challenge

The Indian River Lagoon has faced severe pollution issues caused by stormwater runoff carrying trash, debris, sediments, oils, and nutrients. Without effective treatment, these pollutants degrade water quality, harm fish and shellfish, and contribute to algal blooms. Melbourne needed a solution that could fit within existing stormwater systems, handle large debris loads, and provide advanced pollutant removal, including macro-plastics and hydrocarbons, while remaining easy to maintain.

Solutions

Oldcastle Infrastructure provided precast Nutrient Separating Baffle Boxes® (NSBB®) engineered to deliver high-performance stormwater treatment. These systems feature multi-chamber designs that slow water flow, allowing sediments and debris to settle while skimmers capture floating trash and oils. The NSBB units are designed for easy installation in both new and retrofit applications, minimizing disruption and reducing construction costs.

Key features of this solution include debris-trapping chambers that capture trash and macro-plastics before they break down into micro-plastics, integrated oil skimmers that remove hydrocarbons and chemicals from stormwater, precast construction ensuring durability and simplifies installation in tight urban spaces, and maintenance access allowing for efficient cleanouts using standard equipment.

Sustainability Impact

The baffle boxes installed in Melbourne remove over 4,000 pounds of harmful pollutants annually and have already captured nearly 94 cubic yards of trash and debris this year alone. By intercepting pollutants at the source, these systems prevent contamination of the lagoon, protect aquatic ecosystems, and reduce the risk of micro-plastic pollution. Additionally, the precast design supports long-term sustainability by reducing lifecycle maintenance and enabling scalable deployment.

Overall Impact

Melbourne’s stormwater program demonstrates how Oldcastle Infrastructure’s baffle box technology can deliver measurable environmental benefits. The city has successfully implemented 18 installations since 2015, with plans to add one new system each year. Work is currently underway on what will be the largest baffle box in the world, located near Melbourne Orlando International Airport. These efforts have significantly reduced pollutant loads and improved water quality in the lagoon, reinforcing the city’s commitment to environmental stewardship.

Conclusion

Oldcastle Infrastructure’s Nutrient Separating Baffle Boxes have played a critical role in Melbourne’s lagoon restoration strategy. By combining proven stormwater treatment technology with durable precast construction, these systems provide reliable pollutant removal, easy maintenance, and long-term protection for one of Florida’s most important waterways.

As Melbourne continues to expand its program, Oldcastle Infrastructure remains a trusted partner in delivering sustainable stormwater solutions.

Using AI to target water line repairs

Losing water to undetected leaks, a utilities company in Georgia used AI technology to target downtown water line repairs and address an annual revenue loss of up to $238K.

The challenge: Targeting water line repairs

A utilities company in the third-largest city in Georgia supplies its local residents and businesses with over 15bn gallons of clean water each year.

Distributing this volume of water is no small feat—the utility company’s water supply network encompasses over 1,300 miles of pipe and over 67,000 active and inactive connections.

Like many utilities across the US, however, this water infrastructure is aging, and the miles of pipe and thousands of connections are at risk of leaks.

When it comes to non-revenue water—water lost to leakage after having been abstracted, treated and pumped—Georgia is one of the more progressive states in the US, having required utilities to conduct annual water loss audits since 2012.

As a result, its city leaders knew that the network was losing water—the 2023 water loss audit indicated that its non-revenue water loss could be as high as 27%—but what they didn’t know was where the leaks were.

The solution: CivilSense™ real-time leak detection

Following a consultation with Oldcastle Infrastructure’s smart water consultants, city officials identified CivilSense™ real-time leak detection as a potential solution.

CivilSense™ is the only AI-powered water asset management solution to combine predictive risk assessment with targeted real-time leak detection, and the utilities company opted to deploy the real-time leak detection capability on a focused, high-priority area of the network.

They selected a 20-mile section of the water distribution network covering around 100 blocks in the heart of the city’s downtown area. The area under investigation was a business district containing critical city infrastructure, which would result in significant economic and civic disruption in the event of a major line break.

CivilSense™ field experts deployed 202 acoustic sensors across the targeted section of the network and created a total of 650 investigation sessions. These investigation sessions gathered acoustic data that was fed into the CivilSense™ AI for analysis.

The AI, powered by FIDO Tech, performed comparative analysis using its curated library of more than 2.3 million acoustic signatures to generate Waypoints that indicate potential leaks in the system.

What is a Waypoint?

A Waypoint is an acoustic signature that the AI has assessed to be consistent with a leak based on comparison against a comprehensive library of previously detected and validated acoustic signatures. Waypoints are validated and pinpointed using sensors and a technique called correlation, which confirms and then precisely determines the location of the leak.

Field teams used the results of this analysis to redeploy sensors upstream and downstream of each of the leaks, using cloud computing to validate and pinpoint the location of each leak via a technique known as correlation. The leaks were then marked up to direct water line repairs.

The outcome: water line repairs to save up to $239K

The CivilSense™ team created 650 investigation sessions, from which the AI generated 52 Waypoints. Of these Waypoints, CivilSense™ correctly determined that 19 were previously undetected leaks in the targeted section of network and pinpointed their locations for repair.

The leaks were discovered across a range of network infrastructure assets, including distribution mains, meter valves and vaults, curb stops and hydrants. The largest leak detected was on a main line valve, and was assessed to be losing around 10 gallons per minute.

In total, applying AWWA nominal volumetric values, the leaks were assessed to be losing a combined volume of 93.7 gallons per minute, which equates to around 49.2M gallons of water every year.

With local residential and commercial water rates ranging from $2.01 to $4.86 per thousand gallons, this represents a revenue loss of between $98K and $239K every year.

By revealing this loss and enabling the Georgia utilities company to conduct water line repairs to address the leaks, CivilSense™ is helping the city address aging infrastructure issues, develop water supply resiliency, and improve its finances.

Learn more

The City of Chehalis, Washington, located midway between Portland and Seattle, faced growing challenges with its aging wastewater treatment plant.

Originally built in 1948 and upgraded several times, the plant could no longer meet projected flow rates or stringent Department of Ecology permit requirements.

To address this, the city launched a design-bid-build project for a new Chehalis Regional Water Reclamation Facility, designed to treat an average flow of 1.3 million gallons per day and peak flows exceeding 10 million gallons per day several times per year. The new facility also included a reclaimed water program to irrigate a 250-acre poplar tree plantation, requiring advanced treatment processes. While grit removal was not initially a top priority, the city needed a system that was simple, reliable, and required minimal moving parts.

Challenge

Shortly after start-up, a pump malfunction caused high-grade silica sand from the effluent filters to bypass the intended recirculation path and enter the plant drain system, sending large volumes of sand back to the headworks. This unexpected event posed a serious risk of overwhelming downstream processes, including Sequencing Batch Reactors (SBRs), and could have led to costly shutdowns and equipment damage.

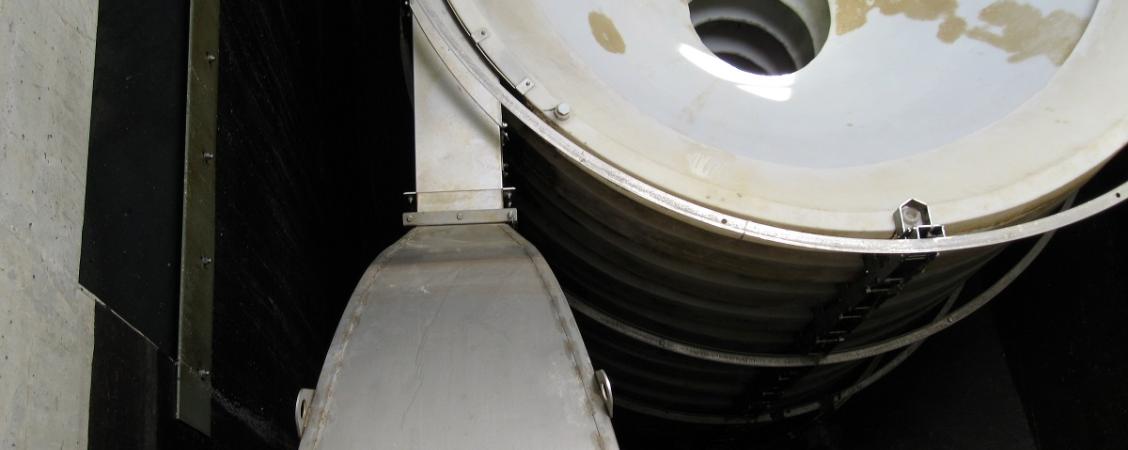

Solution: Grit King®

The facility installed two 11-foot diameter free-standing Grit King® units and a grit classifier as part of its headworks design. Oldcastle Infrastructure’s Grit King system, engineered by Hydro International, uses advanced hydrodynamic separation to remove 95% of grit 150 microns and larger at peak flows of 13 million gallons per day. When the sand filter malfunction occurred, the Grit King® units captured the excess sand, preventing it from reaching critical downstream processes.

Operators increased grit discharge frequency to manage the additional load, and the plant continued operating without interruption. The system’s all-hydraulic design, minimal moving parts, and ease of installation proved invaluable.

As the Wastewater Superintendent noted, “Construction of the new system was easy. It was delivered to the site, and the contractor bolted it in place within days.”

Sustainability Impact

The Chehalis facility incorporates sustainable practices, including reclaimed water reuse of up to 3.5 million gallons per day for irrigation, production of Class A biosolids sold to local farmers, and reduced maintenance and energy use thanks to the Grit King’s pump-free design.

By preventing grit accumulation in SBR tanks, the system reduces cleaning frequency and associated resource use. Annual cleaning of one SBR now reveals only a wheelbarrow of grit compared to what could have been significant buildup without effective grit removal.

Overall Impact

The impact of the Grit King® system has been substantial. The plant avoided costly downtime during a major equipment malfunction, reduced maintenance costs, and improved operational reliability. The grit removal system has been virtually trouble-free since installation, producing cleaner grit with fewer odors and requiring minimal intervention.

As the superintendent summarized, “The Grit King system has worked great without any problems. It has been virtually trouble free.”

Conclusion

The Chehalis Regional Water Reclamation Facility demonstrates how investing in a robust grit removal system can safeguard operations, even when grit removal isn’t initially considered critical. The Grit King system not only met design requirements for simplicity and reliability but also proved its value during an unexpected event, ensuring uninterrupted service and long-term sustainability.

Background

The city of Queen Creek, Arizona, has doubled in population from 35,500 to over 80,000 over the last 10 years, and is projected to reach 150,000 residents at buildout, with an average annual growth rate of 6-7% (according to Queen Creek News). Over the last five years alone, more than 8,000 building permit applications for single-family homes have been filed in Queen Creek.

Within this city, the construction of retail and mixed-use spaces has surged to meet the needs of the community, with hundreds of thousands of square feet of new retail space, homes, and entertainment complexes replacing vacant corners across major intersections.

Hudson Station is one of those up-and-coming developments.

This 90-acre, mixed-use community was designed to support the city’s rapid growth, featuring commercial spaces, single-family homes, and townhomes. Nearly 50% of the town’s budget is dedicated to capital infrastructure, including roads, wastewater, and parks.

Challenge

Flood mitigation is a primary stormwater objective in Arizona, especially during monsoon season when intense rainfall can overwhelm surface drainage systems. Solutions used must not only store stormwater but also promote deep infiltration to recharge groundwater and comply with strict regulatory requirements.

Arizona’s unique soil and environmental conditions make stormwater management particularly challenging. A major issue is the caliche layer—a highly impermeable surface layer that prevents rainwater from naturally infiltrating the ground. Combined with roads, parking lots, and other infrastructure, this significantly limits groundwater recharge. Regulations also require stormwater to be managed onsite and engineered to withstand 100-year flood events, meaning that systems must capture, filter, store, and infiltrate water effectively to protect communities today and into the future.

These dynamics create added pressure for developers and landowners to maximize investment while delivering safe and engaging places to live and work. The Hudson Station project was no exception; its stormwater management system needed to meet onsite storage requirements while supporting optimal land use for amenities like turf areas.

Traditional open-bottom systems limited to depths of only seven feet are not ideal in these conditions as water cannot infiltrate effectively through caliche. This limitation increases risk for stakeholders—including developers, municipalities, and contractors—while the burden of failure ultimately falls on the community. Past failures, such as a sinkhole and CMP storm drain collapse at a nearby Chandler shopping center, highlight the consequences of unreliable systems. Combined with tight site layouts and rising costs, these factors demanded a solution that could deliver performance, reduce risk, and maximize usable land.

Hancock Builders, a leading multifamily housing developer and builder, served as the general contractor for Hudson Station. Ownership of stormwater risk typically falls on project stakeholders, but the impact of failure is shared broadly. For Hancock Builders, finding a reliable solution was critical to project success.

Installation added another layer of complexity. Petra, the earthwork contractor responsible for installing the stormwater system, needed a solution that could be integrated seamlessly with grading and drainage plans, installed safely under Arizona’s soil conditions, and completed without introducing additional risk or delays. Petra’s role was essential in ensuring the system performs as designed and supports the overall project timeline.

Solution

To meet these challenges, the team selected MaxCapture™, an integrated system combining StormCapture® and MaxWell® drywells. StormCapture is a robust underground stormwater detention system with a closed-bottom design engineered for Arizona soils.

A key advantage of StormCapture is its solid base slab, which includes openings only directly above the MaxWell drywells. This design ensures that scour at the bottom of the system does not inundate the drywell with sediment, preventing clogging and failure. StormCapture’s closed-bottom design ensures water containment and system integrity in Arizona’s clay-rich soils, unlike open-bottom systems that risk long-term reliability issues. It also offers superior design flexibility, accommodating varied pipe angles and inverts

Beneath StormCapture, MaxWell drywells enable deep infiltration and groundwater recharge without consuming surface space—critical in Arizona’s clay soils for long-term water stewardship. The Maxwell was designed for the project backed by more than 50 years of soil and area topography knowledge. This experience ensures that the drywell is designed and installed at the proper depth and provides reliable water infiltration for decades to come.

The Oldcastle Infrastructure team partnered with the designers early, using GIS data and thousands of drill records to provide precise specifications for the site. Petra also played a vital role in installing the system safely and efficiently, ensuring alignment with the developer’s strong safety culture.

Other dynamics that made this project successful include the partnership between Oldcastle Infrastructure, the engineering group, and Hancock Builders. Oldcastle Infrastructure provided engineering support early in the process, using the online design tool and working with engineers to ensure that the integrated system was quick and easy to incorporate into grading and drainage plans, streamlining approvals and reducing redesign costs.

Impact

The integrated system offers multiple benefits for the project. Total project cost optimization was achieved despite rising material prices, while space efficiency allowed developers to meet municipal requirements for green spaces and amenities. Oldcastle Infrastructure’s in-house manufacturing of cover plates and tie-off points improved safety during installation, reducing fall hazards and supporting Petra’s installation process.

Sustainability was also a major win for Hudson Station. MaxWell supports groundwater recharge, reducing runoff and replenishing aquifers. StormCapture’s modular design minimizes excavation and material waste, while its durability ensures decades of service life, lowering lifecycle emissions. The system is also engineered for 100-year storm events, ensuring resilience against rare, high-intensity rainfall—a critical consideration given recent significant rain events in Arizona.

Outcome

Hudson Station stands as a model for how advanced infrastructure solutions can overcome regulatory compliance, rising costs, and tight site constraints. By leveraging Oldcastle Infrastructure’s StormCapture and MaxWell systems, and partnering with engineers and contactors for expert installation, the project achieved cost efficiency, sustainability, and enhanced livability, all while meeting Queen Creek’s vision for a thriving, resilient community that seamlessly blends with its surroundings.

The Village of Shiloh is a small community in north-central Ohio with a population of around 690.

Located east of Ohio’s famous Amish Country, Shiloh has a strong Amish and Old Order Mennonite influence.

Background

While the village didn’t need a large wastewater treatment plant, it wanted the benefits of a high-performance grit removal system like the Grit King®, which has been proven to protect downstream processes and improve plant efficiency.

The Problem

Shiloh owns and operates its own wastewater treatment facility, which treats approximately 50,000 gallons per day (189,270 L/d) at average flows and up to 725,000 gallons per day (2,744,424 L/d) at peak flows. Historically, the plant had no grit removal system. The original headworks consisted only of a manual coarse bar screen. Treatment included primary clarification and a trickling filter system, but due to the rudimentary headworks, the facility was becoming increasingly difficult to maintain.

Labor availability was another challenge. The Village had no full-time staff at the wastewater treatment plant and relied on a certified operator to visit once or twice a week to ensure compliance with EPA requirements. This operator also managed several other small treatment facilities in the region, leaving little time for additional maintenance at Shiloh’s plant.

The Solution

With limited staffing and increasing maintenance demands, Shiloh needed a very low-maintenance grit removal system that could provide advanced grit management performance and protect downstream infrastructure under all conditions with minimal supervision. The system had to be simple to install, require little contractor time, and avoid extensive custom site work.

The Village found its ideal solution in Oldcastle Infrastructure’s Grit King® Compact system. This pre-packaged grit removal system was easy to install, fit within the plant’s budget, required minimal maintenance, and could meet the facility’s needs well into the future. The Grit King® Compact, engineered by Hydro International, delivers all the performance of industry-leading grit separation technology in a fully integrated system that outputs clean, dry grit ready for cost-effective disposal.

To keep costs manageable for small plants, internal components in low-wear areas are constructed of durable plastic rather than stainless steel, reducing material costs without compromising performance. The Grit King® Compact is specifically designed for smaller plants, providing total plant protection with very little maintenance—addressing Shiloh’s operational challenges and staffing limitations.

The Outcome

By installing the Grit King® Compact, the Village of Shiloh secured a reliable, low-maintenance grit removal solution that protects its treatment processes, reduces maintenance demands, and ensures compliance with environmental standards. The system’s simplicity and durability make it an ideal fit for small communities with limited resources, delivering long-term performance and peace of mind.

Learn more

Protecting an award-winning plant

The Noman M. Cole, Jr. Pollution Control Plant (NMCPCP) in Fairfax County, Virginia, just west of Washington, D.C., is one of the most recognized wastewater treatment facilities in the United States.

Background

The plant has earned 19 consecutive Platinum Peak Performance Awards from the National Association of Clean Water Agencies—a distinction achieved by fewer than a dozen of America’s 16,500 wastewater treatment plants. NMCPCP discharges into a tributary of the Potomac River, which supplies drinking water for most of the six million people living in the D.C. area.

In addition to traditional wastewater treatment, NMCPCP operates a robust water reuse program. The plant initially treats water to a level suitable for irrigation and industrial applications, and 2-3 MGD (7.6–11.4 MLD) of this pretreated gray water is used internally for plant operations. A pipeline also delivers reclaimed water to Covanta Fairfax, Inc., where approximately 560 million gallons are used annually to operate cooling towers at their 80 MW energy recovery plant. Reclaimed water is also used to irrigate the nearby Laurel Hill Golf Course and county parks, replacing the need for 400 million gallons of drinking water each year.

The Problem

Despite its advanced operations, NMCPCP had no headworks grit removal system. An aging cyclone/screw classifier sludge degritting system was ineffective at removing the large amounts of grit present in sludge. This outdated system provided little protection and was nearing the end of its usable life.

At this facility, excess biosolids are dried, incinerated, and the resulting ash is hauled to a landfill for disposal. Since the cyclone/screw classifier failed to capture grit, significant amounts remained in the ash, increasing landfill volume, handling, and hauling costs, ultimately driving up operational expenses. Cyclone/screw classifier systems typically remove grit 212 microns and larger, leaving finer particles in the 75-212-micron range to pass through and impact downstream sludge treatment processes. Additionally, the system required frequent liner changes, causing costly maintenance and downtime. The plant needed a more robust technology capable of removing finer grit particles and reducing operating and maintenance costs.

The Solution

NMCPCP partnered with Oldcastle Infrastructure to conduct a field trial of the SlurryCup™ and Grit Snail® Advanced Sludge Degritting systems, engineered by Hydro International, to verify its performance in this challenging application. After the trial delivered outstanding results, the plant selected six 42-inch (1.1 m) SlurryCup units and three 2 yd³/hr (1.5 m³/hr) Grit Snail quiescent dewatering escalators. Since installation, the system has significantly reduced maintenance and operational costs while protecting mission-critical biosolids operations from the damaging effects of grit.

The SlurryCup and Grit Snail offer several advantages. It removes over 90% of particles as small as 75 microns (with a specific gravity of 2.65) and captures up to 20 times more grit than a cyclone/screw classifier. Its first-flush solids handling capacity minimizes grit loss, and the classified grit has low organic content (less than 20% volatile solids), reducing disposal volume. The system produces grit with 60% total solids content, operates as an enclosed system for improved odor control, and significantly reduces operations and maintenance costs.

The Outcome

The SlurryCup and Grit Snail continue to provide exceptional performance, protecting NMCPCP’s sludge treatment processes and reducing costs associated with grit-related maintenance and landfill disposal. By implementing advanced sludge degritting technology, NMCPCP continues to uphold its reputation for environmental excellence while improving operational efficiency.

Learn more

Background

The Montrose Boulevard Improvement Project, led by the Tax Increment Reinvestment Zone (TIRZ) in partnership with the City of Houston, focuses on upgrading one of Houston’s most important north-south corridors: Montrose Boulevard, a vital route connecting residents and visitors to major destinations such as the Museum District, Houston Zoo, Texas Medical Center, and the Ismaili Center. The improvement aims to improve mobility, safety, and sustainability while preserving the character of the neighborhood.

Oldcastle Infrastructure played a critical role in the project by supplying reinforced concrete box culverts and pipe for the stormwater drainage system. The contract value was approximately $2.5 million, with manufacturing completed at the North Houston plant. Work began in April 2025 and was completed in January 2026.

The project involved installing roughly 2,200 feet of box culvert and 1,000 feet of reinforced concrete pipe to upgrade stormwater infrastructure. These improvements were essential to address chronic flooding issues in the Montrose area. In addition to drainage upgrades, the project delivered new sidewalks, crosswalks, and improved street lighting to enhance pedestrian safety and accessibility. Roadway surfaces were resurfaced for smoother travel, and mature trees were preserved wherever possible, with additional trees planted along Montrose Boulevard to improve aesthetics and environmental impact.

Challenges

One of the most significant challenges for the project was replacing the outdated drainage system, which relied on undersized 48-inch and 54-inch pipes. This infrastructure could not handle heavy rainfall events, leading to frequent flooding. The new design required installing large 10×10-foot box culverts beneath Montrose Boulevard to provide both conveyance and detention capacity. These culverts were engineered to manage approximately 1.6 million gallons of stormwater, reducing peak runoff and alleviating pressure on downstream systems like Buffalo Bayou. Integrating this system beneath a reconstructed roadway added complexity, as it had to align with mobility improvements while minimizing surface disruption and preserving trees.

Logistical challenges also played a major role. Montrose Boulevard is a high-traffic area with limited space for staging and maneuvering equipment. Deliveries of oversized culverts required strategic scheduling. Unlike typical projects where many trucks can deliver daily, this job required staggered deliveries—sometimes one or two trucks per day, other times five trucks every other day—based on site capacity and traffic conditions. Trucks were spaced 20-30 minutes apart to avoid congestion at the job site.

Additional obstacles included unexpected utility conflicts. Fiber optic and cable lines discovered during excavation could not be relocated, forcing the contractor to develop a creative workaround. Using an excavator, they temporarily pulled the lines aside with ropes during culvert installation and then let them fall back into place. Weather also caused delays as heavy rains during installation led to sediment buildup inside incomplete culverts, requiring cleanup and pushing the schedule back by several weeks.

Solutions

Oldcastle Infrastructure provided innovative solutions to overcome these project challenges, while sister company CRH Americas Materials supplied asphalt. One of the most notable was the custom box culvert design. Original plans called for large junction boxes at four locations with elevation drops of two and four feet. Instead of manufacturing massive junction boxes, Oldcastle Infrastructure engineered custom oversized box culverts (14×10 and 12×10) with internal drop walls. This approach allowed for continuous installation, time savings for the contractor, and the elimination of the need for complex on-site construction. These custom components were cast at the North Houston plant and represented a unique engineering achievement for the team.

Strategic delivery planning was another key solution. Oldcastle Infrastructure worked closely with the contractor to schedule deliveries based on site capacity and traffic conditions, ensuring smooth operations despite space limitations.

Impact

The Montrose Boulevard Improvement Project significantly enhanced roadway safety and reliability by reducing flood risk. The addition of sidewalks, crosswalks, and lighting created a more pedestrian-friendly environment, while resurfaced roads improved accessibility and durability. Preserving mature trees and planting new ones contributed to the neighborhood’s charm and environmental health, reinforcing Montrose Boulevard’s role as a welcoming corridor for residents and visitors.

Sustainability Impact

This project aligns with sustainability principles by protecting and restoring water resources and creating cleaner urban spaces. Improved stormwater management reduces flooding and prevents pollutants from spreading into streets and waterways. Durable concrete solutions ensure long-term performance compared to alternatives like plastic, which lack the necessary strength and hydraulic efficiency for this application. The inclusion of green spaces and pedestrian-friendly features further supports sustainable urban development and community well-being.

Conclusion

Oldcastle Infrastructure’s solutions were specified for the project due to a strong, long-standing relationship built on trust and flexibility. Oldcastle Infrastructure’s willingness to provide custom solutions, such as oversized culverts with drop walls, demonstrated its commitment to supporting the customer’s needs. This collaboration not only solved complex engineering challenges but also reinforced a partnership that will continue to drive future projects.

The Montrose Boulevard Improvement Project exemplifies how innovative engineering, strategic planning, and sustainability can transform urban infrastructure. By addressing flooding issues, improving mobility, and enhancing community amenities, this project sets the standard for resilient, sustainable development in Houston and beyond.

Improving performance and increasing capacity for a wastewater treatment plant retrofit project

Retrofitting a HeadCell®, SlurryCup™, and Grit Snail® grit removal, washing, and dewatering system provided a significant performance improvement over Fox Lake WWTP’s aerated grit basin.

Background

The Fox Lake Wastewater Treatment Plant in Illinois faced a critical challenge with its aging aerated grit basin (AGB). The existing grit removal system was at the end of its useful life and needed to be replaced. The plant had two key requirements for the upgrade: the new equipment had to fit within the existing footprint, and it needed to eliminate grit deposition in the grit basin, which was extremely difficult to remove.

Fox Lake’s plant supervisor discovered the HeadCell® stacked tray grit removal system at the WEFTEC conference in Chicago. He was impressed by the stacked tray concept, which reminded him of lamella systems he had seen before. The design offered increased surface area for grit separation, which would significantly improve performance while staying within the space occupied by the old AGB.

The Problem

The existing aerated grit basin was underperforming. Prior to taking it out of service, a grit study was conducted to evaluate its efficiency. At design peak flow, the AGB should have been removing grit particles 225 microns and larger, and at lower flows, it should have captured even finer particles. However, testing during low flow conditions of only 824 gpm (52 L/s)—when the AGB should have removed all sand particles 50 microns and larger—revealed that the separator was only capturing 58% of incoming grit.

The downstream cyclone/screw washing and dewatering system performed even worse, retaining just 17% of the material delivered to it. This reduced the overall system efficiency to only 10% of influent grit captured. The plant needed a solution that could dramatically improve grit removal efficiency and prevent grit from depositing within the plant.

The Solution

To achieve the required performance, Fox Lake needed to double the surface area for settling grit. The stacked tray design of the HeadCell® allowed the plant to significantly increase surface area while remaining within the existing footprint. An isolation wall was poured to section off part of the old aeration basin, creating a dry pit for the grit pumps, while the remaining space housed the HeadCell® trays. A SlurryCup™ and Grit Snail® replaced the old cyclone/screw washing and dewatering system, providing advanced grit washing and dewatering capabilities.

The Outcome

Testing on a day with flows of 9.4 MGD (36 MLD) proved the new HeadCell® system to be 88% efficient overall. The HeadCell® grit collection chamber achieved 95% efficiency, and the SlurryCup™ and Grit Snail® washing and dewatering system retained 93% of the grit delivered to it. The retrofit provided a significant performance improvement over the previous aerated grit basin, ensuring better protection for downstream processes and improved plant reliability.

Learn more

Using AI to target water line repairs

Losing water to undetected leaks, one forward-looking Georgia city used AI technology to target downtown water line repairs and address an annual revenue loss of up to $238K.

The challenge: targeting water line repairs

When it comes to non-revenue water (NRW)—water lost to leakage after having been abstracted, treated and pumped—Georgia is one of the more progressive states in the US, having required utilities to conduct annual water loss audits since 2012.

As a result, municipal leaders at one Georgia city knew that the water distribution network was losing water—a recent water loss audit indicated that its NRW loss could be as high as 25%—but what they didn’t know was where the leaks were.

With a water supply network comprising over 1,000 miles of pipe and over 50,000 active and inactive connections, the local water utility distributes over 12 bn gallons of clean water every year. Like many utilities across the US, however, this water infrastructure is aging, and the miles of pipe and thousands of connections meant that reliably detecting and locating leaks was a challenge.

The solution: CivilSense™ real-time leak detection

Following a consultation with Oldcastle Infrastructure’s smart water consultants, city officials identified CivilSense™ real-time leak detection as a potential solution.

CivilSense™ is the only AI-powered water asset management solution to combine predictive risk assessment with targeted real-time leak detection, and the city’s water utility opted to deploy the real-time leak detection capability on a focused, high-priority area of the network.

They selected a 20-mile section of the water distribution network covering around 100 blocks in the heart of city. The area under investigation was a business district containing elements of critical city infrastructure, which would result in significant economic and civic disruption in the event of a major line break.

CivilSense™ field experts deployed 202 acoustic sensors across the targeted section of the network, and created a total of 650 investigation sessions. These investigation sessions gathered acoustic data that was fed into the CivilSense™ AI for analysis.

The AI, powered by FIDO Tech, performed comparative analysis using its curated library of more than 2.3 million acoustic signatures to generate Waypoints that indicate potential leaks in the system.

What is a Waypoint?

Field teams used the results of this analysis to redeploy sensors upstream and downstream of each of the leaks, using cloud computing to validate and pinpoint the location of each leak via a technique known as correlation. The leaks were then marked up to direct water line repair activities.

The outcome: water line repairs to save up to $239K

The CivilSense™ team created 650 investigation sessions, from which the AI generated 52 Waypoints. Of these Waypoints, CivilSense™ correctly determined that 19 were previously undetected leaks in the targeted section of network, and pinpointed their locations for repair.

The leaks were discovered across a range of network infrastructure assets, including distribution mains, meter valves and vaults, curb stops and hydrants. The largest leak detected was on a main line valve, and was assessed to be losing around 10 gallons per minute.

In total, applying AWWA nominal volumetric values, the leaks were assessed to be losing a combined volume of 93.7 gallons per minute, which equates to around 49.2M gallons of water every year.

With local residential and commercial water rates ranging from $2.00 to $4.86 per thousand gallons, this represents lost revenue of between $98K and $239K every year. Add in variable production costs, and the real losses are far higher.

By revealing this loss and directing repair teams to conduct targeted water line repairs to address the leaks, CivilSense™ is helping the city to address aging infrastructure issues, develop water supply resiliency, and improve its finances.

Learn more

Background

Located just 20 miles from downtown Phoenix, the city of Chandler, Arizona, has experienced massive growth over the past four decades. In 1980, the city had a population of less than 30,000. Today, it exceeds 250,000, driven by the rapid expansion of technology and major employers like Intel®, which employs nearly 12,000 people in the region. This population boom placed significant strain on the city’s wastewater infrastructure.

The Chandler Airport Water Reclamation Facility (WRF) was built in 1998 and is one of three WRFs in the area. Given the scarcity of water in south-central Arizona, Chandler reclaims and reuses 100% of its wastewater. The effluent meets Class A+ water standards, allowing direct use in lakes, golf courses, aquifer recharge, and landscape irrigation. In 2009, the plant underwent a major expansion to treat 15 MGD (57 MLD). At the time, the $76 million project was the largest capital improvement in the city’s history. Over two decades, the facility expanded four times to reach its current capacity of 27 MGD (102 MLD). Despite these upgrades, one critical issue remained unresolved: grit removal.

The Problem

From the start, the plant operated without a grit removal system. As flows increased, grit accumulation caused severe operational challenges, including frequent maintenance across multiple processes, reduced operating capacity, shortened equipment life, and increased energy costs due to grit-laden aeration basins. To manage the problem, the plant hired contractors every two to three years to remove accumulated grit—a costly and labor-intensive process that consumed hundreds of thousands of dollars.

Determined to eliminate this recurring expense, Chandler engaged Wilson Engineers to evaluate grit removal technologies. Independent testing revealed that 79% of influent grit was larger than 300 microns, but a system designed for 300-micron removal would only remove 27% of grit when settling velocity was considered. A design targeting 106-micron Sand Equivalent Size would capture 99% of influent grit. The influent grit testing confirmed that the HeadCell® system with a 106-micron design would provide the solution the Airport WRF needed.

Located adjacent to a busy municipal airport, the plant had limited space for a new headworks grit removal system. Given decades of experience struggling with unchecked grit, the Airport WRF wanted a low-maintenance separation system with minimal moving parts and a proven track record of fine-grit removal performance.

The Solution

Wilson Engineers evaluated aerated grit basins, mechanically induced vortex systems, and stacked tray grit separation. They determined that the HeadCell®, a stacked tray grit removal system engineered by Hydro International, was the best solution. The HeadCell® has no moving parts, and its stacked tray design provides increased surface area in a very small footprint. With nearly 1,000 installed units worldwide, HeadCell® offers decades of independently verified performance.

In the summer of 2018, Mortensen Construction installed an Advanced Grit Management® system consisting of HeadCell®, TeaCup®, and Grit Snail® units. This configuration provides total plant protection for peak flows up to 45 MGD (170 MLD), with 95% removal of grit 106 microns and larger at peak flows and 95% removal of grit 75 microns and larger at average flows. After start-up, the new system’s performance was independently measured on-site, and the results exceeded expectations.

The Outcome

The new grit removal system transformed operations at Chandler Airport WRF. It eliminated costly grit cleanouts, protected downstream equipment, reduced energy consumption, and extended equipment life and reliability. By investing in a proven solution, Chandler resolved a decades-long challenge and secured sustainable, efficient wastewater treatment for a rapidly growing community.

Learn more

- See the latest generation of the TeaCup®, the OpTeaCup®

The Situation

The Philadelphia Zoo is home to some of the most iconic wildlife in the region, and when plans for a new flamingo habitat began, the project required reliable infrastructure.

Oldcastle Infrastructure’s Telford plant was selected to deliver a custom drainage solution that would support the habitat while meeting strict environmental and operational requirements. What started as a straightforward precast slab installation quickly evolved into a specialized drainage system designed to manage runoff and protect the health of the flamingos.

The Challenge

The initial scope of the project involved installing large precast slabs; however, during construction, the contractor identified a critical need for drainage and filtration components to ensure proper water management.

This presented two challenges:

- The design required smaller, highly customized components outside Oldcastle Infrastructure’s typical large-scale product range.

- The zoo remained open to visitors throughout the project, demanding precise scheduling and unconventional delivery routes through pedestrian pathways.

- The solution had to fit within the habitat footprint, maintain water quality, and be installed without disrupting zoo operations.

The Solution

Oldcastle Infrastructure responded by engineering a tailored system of trench drains and catch basins equipped with specialized filter media. Each drain featured a durable grate for debris protection and easy maintenance access, while the underlying filter media captured impurities before stormwater exited the habitat. Components varied in size—from compact units to taller structures—but all were designed for durability and performance.

Production and installation were completed in phases between September 2024 and January 2025. Materials were transported via flatbed trucks and escorted through zoo pathways during early morning hours to avoid visitor traffic. Once onsite, the team installed trench drains and catch basins, followed by filter media placement.

Despite logistical complexity, Oldcastle Infrastructure’s adaptability and engineering expertise ensured the project was completed within six to eight weeks.

The Outcome

The custom drainage system plays a vital role in maintaining a clean, sustainable environment for the zoo’s flamingo habitat. By effectively managing runoff and filtering impurities, Oldcastle Infrastructure supported the Philadelphia Zoo in achieving its environmental goals while enhancing the visitor experience.

For the Telford team, the project was more than just another job—it was an opportunity to contribute to a space that the community can enjoy for years to come.

Next

Leak detection technology reveals 22 previously undetected leaks

The City of Hailey, Idaho, deployed a new AI-driven leak detection technology on 62 miles of its water distribution network and found 22 previously undetected leaks that were losing a total of 59 million gallons of clean water every year.

The challenge:

The City of Hailey is a small city situated in Idaho’s Wood River Valley, with a population of a little over 9,900 people. Though both the Big Wood and Little Wood rivers run through the region, Hailey’s water distribution network was in need of attention.

Between 2019 and 2023 the city estimated that some 29% of the water that it was producing was not reaching consumers. This unaccounted-for water, or non-revenue water (NRW), reached 50% during the winter months.

The city identified three possible causes of this NRW:

- Leaks in distribution system pipes

- Faulty or inaccurate water meters

- Unmetered connections

The problem with leaking water pipes, however, is that they are invisible, and therefore difficult to locate—or even detect—with any degree of confidence using traditional detection methods.

To address this, city leaders solicited assistance from specialized leak detection companies.

The solution: CivilSense™ real-time leak detection technology

Solution selection

City leaders asked Eric Landsberg, PE of Clear Solutions Engineering to evaluate leak detection technologies and services from three different providers: Echologics, Asterra, and Oldcastle Infrastructure.

Echologics offered leak detection technology that the city’s workers would install and operate. Relying on existing city resources to undertake both deployment and analysis was considered unviable as the city’s workforce was already stretched thin.

Asterra offered analysis of satellite imagery, using data over a range of wavelengths to identify areas where soils were saturated, suggested the possible presence of a leak. However, local geography is characterized by rocky terrain that does not retain water, meaning that this technique would be unsuited to the requirement.

Mr Landsberg instead recommended that the city use Oldcastle Infrastructure’s CivilSense™ solution, an AI-driven risk analysis and real-time leak detection technology that uses acoustic sensors and an AI trained on over 2.3 million acoustic signatures to detect, locate and size leaks in the water distribution network.

Landsberg recommended the CivilSense™ approach because of its “turnkey” nature, in which the CivilSense™ team would deploy sensors and the AI would conduct the analysis, as it avoided adding to the resource burden on the city’s workforce. He also noted the fact that its >93% accuracy meant that it delivered superior leak detection than either competitor.

The project

Oldcastle Infrastructure deployed CivilSense™ on a 62-mile section of the water distribution network, including mains, service lines and related infrastructure.

CivilSense™ field experts deployed acoustic sensors across the targeted section of the network, and created a total of 807 investigation sessions. These investigation sessions gathered acoustic data that was fed into the CivilSense™ AI for analysis.

The AI, powered by FIDO Tech, performed comparative analysis using its curated library of more than 2.3 million acoustic signatures to generate 220 Waypoints that indicate potential leaks in the system.

What is a Waypoint?

A Waypoint is an acoustic signature that the AI has assessed to be consistent with a leak based on comparison against a comprehensive library of previously detected and validated acoustic signatures. Waypoints are validated and pinpointed using sensors and a technique called correlation, which confirms and then precisely determines the location of the leak.

The field teams used the results of this analysis to redeploy sensors upstream and downstream of each of the Waypoints, and—using cloud computing and a technique known as correlation—this additional acoustic data enabled the AI to eliminate Waypoints that were not leaks, and to validate, locate and size the Waypoints that were leaks. The leaks were then marked up in situ to direct the resulting repair activity.

The outcome

The CivilSense™ team created 880 investigation sessions, from which the AI generated 220 Waypoints. Of these Waypoints, CivilSense™ analysis identified 22 previously undetected leaks in the targeted section of network, and pinpointed their locations for repair crews.

The leaks were discovered across a range of network infrastructure assets, including main lines, service lines and fire hydrants. Of these, seven were assessed as large leaks, six as medium and four as small. In addition, CivilSense™ was able to pinpoint the location and assess the sizes of five leaks that were known about but which could not be located.

In total, applying AWWA nominal volumetric values, the leaks were assessed to be losing a combined volume of around 59.2M gallons of water every year.

By revealing this loss and enabling the City of Hailey to conduct targeted repairs to address the leaks, CivilSense™ leak detection technology is helping the city address its leaks, improve system efficiency and make budgetary savings that can be reinvested into the community.

Learn more

The Situation

A leading energy provider that services customers in Maryland and the District of Columbia approached Oldcastle Infrastructure for a solution to repair a set of critical substations. Federal agencies require utilities to identify key substations essential to the performance of the power grid. There are approximately 55,000 substations nationwide, many in extreme disrepair. In this case, the concrete trenches housing multiple cable platforms in the substations were breaking down and cracking. If this critical substation were to power down, it could have disastrous implications for the electrical grid.

The Challenge

Trenches physically protect communication cables that control the devices that automate the grid. Replacing these trench systems in the substations safely and without taking an outage presented significant obstacles. Especially when considering that the critical power surrounding Washington DC is 500 kV.

To repair these trenches, the contractor would typically remove the trench and in the process disturb the cables. Additionally, rebuilding the trenches without disturbing the cables was simply not feasible.

Any disturbance or break of the existing cables could cause an outage in the substation. Also, during the problem-solving stage of the project, we were presented with another unique situation: the site’s physical position restricted the ability to use mechanical means inside the substation.

The repair work also had to be accomplished with the substation operating hot. If an outage were to occur, all cabling would have to be exposed, dug up and rerouted, which would take up to a year or more to remedy. This would again mean the loss of power to critical areas.

The Solution

The first two traditional solutions presented, namely cast-in-place and precast cement, were rejected, with cast-in-place immediately judged as being unviable due to the site limitations on heavy mechanical equipment.

The Oldcastle Infrastructure team approached the drawing board on this highly challenging project with a collaborative, problem-solving framework. Through customer-centric ideation and an innovative mindset, we arrived at an out-of-the-box solution.

We found a solution to reconfigure a STAKKAbox Ultima Connect product. Normally used to make highly effective manhole vaults, individual pieces of the modular STAKKAbox Ultima Connect system were repurposed to make a trench that was high strength while also being lightweight and flexible.

The team demonstrated the STAKKAbox Ultima Connect and installed a pilot section to determine if the product would work. Although skeptical at first, the construction team realized the value of the Ultima Connect system and the speed of installation. More importantly, the key requirement of not touching or moving communications cables would be met.

Additional enhancements included:

- Supplying orange Plastibeton custom covers to give a clear visible signal of pedestrian rating.

- Redesigning support beams to reduce weight and allow for greater interior room.

- Designing supports to ease installation and increase lateral support on the structure.

The Outcome

Safer substation

As safety hazards were eliminated, crews can now walk safely around the substation. All cable is encapsulated and extremely well protected by the STAKKAbox Ultima Connect system. Safety orange Plastibeton custom covers are now much easier to notice to prevent vehicular traffic.

Better protected grid

Our protective Plastibeton custom covers are built to last. They will not decay or break down over time.

Zero maintenance

Yes, zero maintenance requirements for years to come. The customer really appreciates that.

Trusted partnership

The customer asked, “Can you fix my problem?” In close consultation with customer and contractor, the team found the best solution for this challenging scenario.

Customized solution

The flexibility of STAKKAbox Ultima Connect system allowed for the development of this clearly lighter, non-conductive product that can be assembled quickly, lifted safely by hand and fits perfectly into tight, complex configurations.

Blueprint for success

There are some two-dozen more substations in the region waiting for this customized fix, some with up to 10,000 feet of trench in substations measuring two miles long.

Robust connections

The ability to reach out across the network of CRH companies and innovate together is key to Oldcastle Infrastructure’s operational success. It’s all about finding the right solution for the customers’ needs.

Ultimately, the team created an innovative system to replace the existing trench, while allowing for future expansion. The customer was convinced the solution worked once the concept was proven on site.

Download this Case Study

The Situation

Located in Northeastern Pennsylvania’s Lackawanna County, Elmhurst Township is a small community intersected by State Route 435, a key connector to I-84 and the nearby towns of Scranton and Moscow.

Along its path, SR 435 crosses the heavily used Delaware Lackawanna Railroad and a tributary of Roaring Brook before passing over Roaring Brook itself – designated as a Class A Wild Trout Water feeding into the Lackawanna River.

The existing structures—a monolithic concrete and plate girder railroad bridge and a reinforced concrete arch—were assessed by the Pennsylvania Department of Transportation (PennDOT) as structurally deficient due to signs of significant deterioration. As a result, replacement was necessary to maintain the safety and reliability of the infrastructure for the traveling public.

The Challenge

As part of the SR 435 bridge replacements, additional improvements were required along Front Street and within the existing railroad drainage system to safely relocate traffic to a temporary roadway during construction.

Relocating traffic created new demands on this section of roadway, requiring upgrades to handle increased traffic volume. This included replacing the worn concrete pipes under Front Street and two aging box culverts beneath the railroad.

This reconstruction effort presented several challenges, including working adjacent to an active railroad, protecting a sensitive local river tributary, and operating within tight site constraints and difficult terrain.

The Solution

As part of the design strategy, PennDOT specified the use of precast concrete box culverts to preserve the natural flow of the tributary feeding into Roaring Brook, while minimizing environmental disruption. Precast culverts were selected for their proven durability, structural integrity, and efficiency in installation—qualities that support design lifespans exceeding 100 years.

To further align with environmental objectives, the culverts were designed with integrated baffles, allowing for the placement of natural streambed material within the structure. This feature helps maintain aquatic habitat continuity and supports the ecological health of the waterway.

PennDOT engaged Susquehanna Valley Construction Corporation (SVCC) to execute the construction phase of the project. SVCC selected Oldcastle Infrastructure as the preferred precast supplier, with all components manufactured at Oldcastle’s Telford, Pennsylvania facility, located just north of Philadelphia.

“As the contractor, it was critical that the culvert sections and hardware were delivered on time, in the requested sequence, and that all sections fit together seamlessly. Oldcastle Infrastructure’s shop drawings were precise and accounted for the tight field conditions between the staged box culvert installation and the railroad relocation.

Oldcastle Infrastructure not only delivered a high-quality product that met the project’s needs but also provided an experienced technician to properly install the post-tensioning elements on the day of assembly.

Oldcastle Infrastructure’s quality products and knowledgeable support enabled SVCC to successfully complete all contractual requirements for Front Street and the staged railroad box culverts.”

– Atlee Eshleman, Engineer, Susquehanna Valley Construction Corporation

The Outcome:

The project required two precast concrete box culverts to complete this initial phase of improvements:

- Culvert 1: 7’ x 14’ opening, 38’ long and was used to replace the aging concrete pipes beneath Front Street.

- Culvert 2: 7’ x 14’ opening – with a slightly thicker roof to accommodate railroad loading – 90’ long and was used to replace the deteriorated culverts under the railroad.

Installation of the second culvert was completed in two stages, coordinated closely with the railroad relocation to ensure uninterrupted rail operations.

This streamlined precast box culvert solution highlights the strength, durability, and precision of Oldcastle Infrastructure’s modern concrete systems.

Beyond improving the structural integrity—and therefore the safety—of the local transportation network, these new culverts also provided environmental benefits by maintaining and protecting the local aquatic ecosystem.

“The first priority for any project should always be safety, but projects like this remind us that if we select the right solution, we can deliver a range of benefits. Our box culverts not only provide a safe, solid base to upgrade local transport infrastructure but also serve to protect and maintain part of the local ecosystem.”

– Emily Schneider, VP of EHS & Sustainability, Oldcastle Infrastructure

Learn more

Retrofitting a HeadCell®, SlurryCup™ and Grit Snail® grit removal, washing and dewatering system provided a significant performance improvement over Fox Lake’s aerated grit basin.

The Problem

The existing aerated grit basin (AGB) grit removal system at Fox Lake Wastewater Reclamation Facility in Illinois was at the end of its useful life and needed to be replaced.

Plant operators had two requirements for the replacement: they wanted to retrofit the new equipment in the existing area and to eliminate grit deposition in the grit basin, which was very difficult, time-consuming and costly to remove.

Fox Lake’s Plant Supervisor Steve Vella saw the HeadCell® at WEFTEC in Chicago. He liked the stacked tray concept developed by Hydro International’s grit management experts and thought it would be the ideal solution to their plant’s grit problem.

The stacked tray design would allow them to significantly increase their treatment surface area, which would increase their grit system performance while staying within the existing area used by the AGB.

The Solution

To get the performance required to prevent grit from depositing within the plant, plant operators needed to double the surface area for settling grit. The stacked tray design of the HeadCell® allowed them to significantly increase their surface area while staying within their existing footprint.

An isolation wall was poured to section off a portion of the old aeration basin, making a dry pit for the grit pumps. The rest of the basin was used to house the HeadCell®. A SlurryCup™ and Grit Snail® replaced the old cyclone / screw washing and dewatering system to provide a complete Advanced Grit Management® system.

Testing

Prior to taking the AGB out of service, a grit study was performed on it. At the design peak flow, the aerated grit basin should have been removing 225-micron grit. At lower flows, the AGB should have performed even better; unfortunately, it did not.

Testing was performed during low flow conditions of only 824 gpm (52 L/s) when the aerated grit basin should have been removing all sand particles 75 micron and larger.

The data revealed that the separator was only capturing 58% of the incoming grit. To make matters worse, the cyclone / screw washing and dewatering system was retaining just 17% of the material delivered to it. This further reduced the overall system efficiency to only capturing 10% of influent grit.

The Outcome

Testing on a day with flows of 10 Mgal/d (38 MLD) proved the HeadCell® system to be 88% efficient overall.

The HeadCell® grit collection chamber alone reached 95% efficiency, while the SlurryCup™ and Grit Snail® washing and dewatering system successfully retained 93% of the grit it received. This represents a substantial performance improvement over the previous AGB system.

The new grit system significantly reduced the volume of grit that was passing through the old AGB and entering downstream treatment processes. The HeadCell ®-based Advanced Grit Management® setup minimized clogging issues, addressing the long-standing challenge of difficult grit removal.

As a result, the frequency of cleanouts was reduced, leading to lower maintenance costs, decreased labor demands, and improved operational reliability.

Upgrading for the future

Five years after installing the new grit removal system, Fox Lake installed a second HeadCell®, SlurryCup™, and Grit Snail® system to treat peak flows that exceeded the 25 Mgal/d (95 MLD) capacity of the original system.

The second system treats up to 12.5 Mgal/d (47 MLD) and is used in conjunction with the original HeadCell® system to treat the peak wet weather flows.

Together, the systems ensure Fox Lake’s wastewater reclamation plant remains resilient and efficient, even during peak wet weather events, demonstrating a long-term commitment to operational excellence, sustainability, and environmental stewardship.

Learn more

Precast concrete box culvert bridge replacement

Precast concrete box culverts replaced an aging bridge in Putnam, CT, preventing erosion and preserving fish passage in the brook that flows beneath.

The situation: aging infrastructure

Danco Road is a small road on the outskirts of Putnam, Connecticut that connects Park Road—and by extension I-395—with several local small businesses.

The road crosses Perry Brook, and the bridge over this small tributary of the Quinebaug River was determined to be in dire need of repair. The bridge culvert, originally made with corrugated metal pipe, had corroded away, and the bed of the brook was suffering from erosion.

Putnam Mayor Barney Seney told local radio station WINY that the town’s bridge inspection program had identified the bridge on Danco Road as being in poor condition:

“So, in the last eight years we’ve had a program to address this issue, and the Danco Road bridge was one of the bridges that, when it was inspected, it was determined that it was ready to fail.”

The town decided that the bridge needed to be replaced.

The challenge: disruption, erosion and fish passage

While the bridge is small—under 20 ft long—its replacement nonetheless presented challenges.

In the first instance, the roadway could not be closed down completely as it was the only route leading to and from the businesses and local residents.

In addition, the bridge needed to enable Perry Brook to flow freely beneath it, preventing erosion beneath the road and allowing fish to continue to pass.

The solution: precast concrete box culverts

The town made $1.6M available for the bridge replacement project—half funded from Putnam’s capital improvement funds, and half funded by grants from the State of Connecticut—and specified that the bridge be replaced by a series of four-sided precast concrete box culverts.

The town engaged general contractor NJR Construction of Thomaston, CT to carry out the work, and NJR Construction identified Oldcastle Infrastructure’s precast concrete box culverts as the preferred solution.

Supplied by the nearby Avon, CT plant, the box culverts are strong, versatile and extremely durable, providing corrosion resistance and design lifetimes of over 100 years.

“The placement of the new precast concrete box culvert bridge was the critical component of the project and needed to be fabricated and ready to be delivered to the project to meet our very aggressive schedule,” said Nicholas Mancini Jr, President of NJR Construction. “Tony Letizio of Oldcastle Infrastructure was instrumental in making sure the precast was properly fabricated and ready for delivery as our schedule required. Mr. Letizio maintained contact with our office and field personal throughout the entire process, allowing us to perform the work required for stage 1 of the project ahead of schedule.”

The outcome: safe infrastructure and environmental preservation

Although the project was delayed several times due to flooding caused by intense summer storms, the bridge replacement was carried out successfully and the new bridge is now in place.

The bases of the precast concrete box culverts were lined with small stones to prevent erosion and to provide a naturalistic riverbed to support the aquatic environment of Perry Brook, and the Connecticut Department of Energy & Environmental Protection (DEEP) has expressed satisfaction with its implementation.

Aging infrastructure is an acute issue across the US, and the Danco Road bridge is a perfect example of how even the smallest structures are in need of attention. With the 100+ year lifetime of precast concrete, however, this small bridge replacement project will have a lasting impact on the environment that surrounds it.

“Precast concrete is not often thought of as an environmental solution, but it all comes down to how it’s used,” said Emily Schneider, VP of Sustainability at Oldcastle Infrastructure. “By providing a stable, durable base on which a natural substrate can take hold, the box culvert preserves the character of Perry Brook and enables fish passage as though it were a natural environment, and its corrosion resistance and reliably long lifetime mean that this brook will remain in good condition for many decades to come.”

Learn more

How Collaborative Field Monitoring in North Carolina is Shaping the Future of Stormwater Technology

As towns and municipalities across the country become more developed, forests and meadows are being replaced by pavement and buildings. When it rains, stormwater runs off roofs and parking lots into the street, picking up everything from fertilizer, pesticides, bacteria and other pollutants. The untreated run-off then makes its way through storm drains and ditches to our rivers, lakes and oceans.

There’s no getting around it: polluted runoff is one of the greatest threats to clean water in the US. And without clean water, our world would be unrecognizable.

Fortunately, there are studies in the field that are helping to do something about it. Download the white paper to find out more.

Cutting the cost of water loss

Bartow County Water officials turned to AI-driven leak detection to identify, pinpoint and fix leaks in their water distribution network—helping them cut their annual water costs by $130,000.

The challenge: out of sight, not out of mind

Bartow County Water supplies around 7.5 million gallons of water every day to its 108,000 residents in northwest Georgia, and as the utility acquires over 95% of its water from five external water systems it is strategically imperative that the water is used efficiently and cost-effectively.

The city’s drinking water distribution network is large and complex, with around 24,000 connections spread across 900 miles of pipes of varying materials and diameters, and like many networks in the US, it suffers from water loss due to leakage.

Officials knew that the network was losing water to leaks, but as water pipes are buried underground it was unable to detect and locate the leaks that were causing this non-revenue water loss. Resources were being used to fix large leaks and main breaks instead of driving efficiency by proactively preventing them. City leaders decided that they needed to take action.

“We were mostly fixing leaks instead of finding them, and that was a costly way to address an ongoing problem. We were at the point where our leaks were so bad we just had to fix them without proactively trying to predict and find potential leaks. It was past time to see what we were actually dealing with here.”

Lamont Kiser, Director of Bartow County Water

The solution: CivilSense™ AI-driven leak detection

City officials identified CivilSense™ real-time leak detection as the solution that could make their invisible network visible, and they partnered with Oldcastle Infrastructure to address a high-priority area of the network.

Bartow County Water identified an 80-mile section of the water distribution network that they considered to be at elevated risk of leaks, and the Oldcastle team designed a leak detection project that would provide detailed, specific insight into leak conditions.

Oldcastle experts strategically deployed highly sensitive acoustic sensors at almost 800 different points across the network, gathering detailed acoustic data that was fed into a proprietary AI.

The AI, powered by FIDO Tech, analyzed the data and used comparative analysis against its curated library of more than 2.3 million acoustic signatures to detect, locate and assess the size of each leak.

Using this analysis, field teams then redeployed sensors upstream and downstream of each of the identified leak locations and used cloud computing to pinpoint the location of each leak via a technique known as correlation.

The outcome: reduced water cost

CivilSense™ detected nine previously unknown leaks in the section of network, including four large leaks that were discharging up to 20 gallons per minute and which represented a high risk of becoming a costly and disruptive main break.

The leaks were discovered across a range of network infrastructure assets, including service lines, mains and hydrants.

In total, CivilSense™ discovered leaks that were losing a combined volume of 83 gallons per minute, which equates to around 43M gallons of water every year.

By addressing these leaks, Bartow County Water achieved a 17% reduction in non-revenue water that translates to a saving of $130,000 in variable production cost every year. Given the city’s reliance on external water sources, this reduced water cost and increased water distribution efficiency improves not only its sustainability and water resilience, but also its finances.

The city has subsequently agreed a three-year follow-on partnership for CivilSense™ to analyze additional sections of the network to drive further water cost efficiencies.

Learn more