Used to Maximize Holding Capacity at University of Arizona $100M Cancer Center

Phoenix, AZ

DESIGN & CONSTRUCTION TEAM

Owner: University of Arizona

Distributor: James Cook & Hobson (JCH), Phoenix, AZ

Design Engineer: Dibble Engineering, Phoenix, Ariz.

University of Arizona $100 million Cancer Center at Dignity Health St. Joseph’s Hospital and Medical Center clinic. As a National Cancer Institute – designated comprehensive cancer center, the six-story, 230,000 sf building provides chemotherapy, infusion, radiation oncology, and diagnostic imaging. St. Joseph’s Hospital and Dignity Health will operate the facility as well as leasing space in it.

THE CHALLENGE

Late placement of electrical utilities prevented the building from using a gravity drain. The shape of the basin was of particular interest because of the extra per foot storage volume. Also, there was very little room to fit the station.

The OneLift pump station was the contractor’s product of choice due to the speed in product delivery and installation, plus it was specified in the bid.

Oldcastle Infrastructure’s OneLift pump station is installed between the building and sidewalk on a very busy street in downtown Phoenix.

The OneLift submersible pump station with integral valve vault was pre-assembled as a complete package, prior to delivery, to ensure the proper fit for concrete and all components. Oldcastle Infrastructure incorporated and pre-installed all equipment in their factory, minimizing re-assembly time and potential problems in the field.

The installation took about 2-1/2 hours and every one was very pleased with the results of this new system. The contractor also mentioned that they saved time and money with the OneLift in lieu of building from scratch.

PRECAST STRUCTURE

OneLift Model RC509x1410-0-H20-4P1-0B pump station package with Integral valve vault, interior fillet and exterior anti-floatation collar: Overall exterior height: 15’-6”

OLDCASTLE INFRASTRUCTURE PRODUCTS USED

OneLift Model RC509x1410-0-H20-4P1-0B pump station package. Integral valve vault, interior fillet and exterior anti-floatation collar: Overall exterior height: 15’-6”. Cored opening and MH boot for 4” incoming air vent/emergency overflow. Oldcastle Infrastructure’s OneLift continues to provide customers with beneficial solutions, high quality construction, and rapid supply at an overall cost savings.

STANDARD EQUIPMENT INCLUDED

- Installation of (2) submersible sewage pump base elbows

- 4” Interior SCH80 PVC discharge piping, fittings and SS hardware for flange packs as required to common pump station discharge (ending plain-end approx. 12” outside of station).

- (2) Flanged check valves (L&W), epoxy coated

- (2) Flanged plug valves w/lever operator, epoxy coated

- (2) Galvanized foor pipe stands in valve vault

- (1) Valve vault drain w/trap & back water valves to pump station

- (1) Wall-mounted aluminum ladder in valve vault

- (1) Manhole boots as required for discharge piping Manhole boot(s) as required for inlet(s)

- (1) 30” x 36” aluminum valve vault access hatch

- (1) 1 ½” SCH 40 PVC hatch drain from valve vault hatch to pump station

- (1) 30” x 48” aluminum pump access hatch with safety grating,

- (2) Sets 304 Stainless steel pump removal guide rails, SCH40 (upper/intermediate guide brackets supplied with base elbows)

- 4-Gang electrical coupling access for incoming conduit from control panel

- (1) 4” glue-fitting access for PVC passive vent intake piping run underground to intake area. UG vent-run

INNOVATION

Single Structure design

The factory built OneLift pump station offers a monolithically cast valve vault, in what is typically an unused portion of the pump station. This results in a significantly smaller footprint – up to 50% smaller than conventional 2 structure pump stations – allowing it to fit tight sites. The innovative shape and structural design provides ample space for the interior valve vault, while increasing workable system volumes and decreasing the depth of the excavation. The single structure of the OneLift pump station eliminates any potential differential settlement issues, allows for a quick and easy installation by eliminating the typical two-tier excavation of conventional stations, and is proven to be a cost effective method of providing a high quality pump station solution with rapid and reliable delivery. With the OneLift pump station you get fast turnaround time on submittals; which include standard structural and mechanical components.

Find out more about the Oldcastle Infrastructure OneLift Pump Station.

Download Full Case Study

Precast Concrete “Z” Superstructures and Wall Panels Used to Construct

Seattle Washington Waterfront, Seattle, WA

DESIGN & CONSTRUCTION TEAM

General Contractor: J E Dunn Construction

Project Manager: Kyle Quigley

Owner: City of Seattle, Wash.

General Contractor: Joint Venture team of Mortenson-Manson, general contractor/construction manager (GC/CM).

The Elliott Bay Seawall project, part of Seattle’s Water-front Program, is a joint effort between the City of Seattle Department of Transportation {SDOT), and the U.S. Army Corps of Engineers {USACE) to replace the 100 year old seawall. Built between 1916 and 1936, the failing wall has suffered significant timber decay and deterioration of the structure from continued exposure to storm waves and tides, including damage from the magnitude 6.8 Nisqually Earthquake. Oldcastle Infrastructure, Auburn, WA was selected by the Joint Venture team of Mortenson-Manson, general contractor/ construction manager {GC/CM), to supply precast concrete Z-shaped superstructure segments and 20-foot tall seawall face panels for the reconstruction of the new $330 million Elliott Bay Seawall at the waterfront in downtown Seattle, Wash.

THE CHALLENGE

Acting as a barrier between Elliott Bay and the waterfront, the new seawall structure consists of a cast-in-place support slab with custom precast concrete face panels, precast concrete zee shaped superstructure segments, and precast sidewalk panels. The precast elements were designed to be connected to the support slab by closure walls and a shear block. Once the “Z” superstructure segments were in place, concrete was poured to form a closure wall and edge beam, which connects the zee panels to each other on the land side and the waterside, respectively. This innovative solution resulted in expedited construction and minimized the impact on adjacent piers, which are valuable sources of tourism for the city.

To successfully construct the new seawall, Oldcastle Infrastructure worked closely with Mortenson-Manson and Paron’s to complete the design and engineering of the fascia panels and specialty “Z” superstructure segments essential to the seawall’s stability. The “Z” superstructures were a critical step in building the seawall and acts as the concrete backbone of the new seawall’s cantilevered sidewalk. These large, zee-shaped concrete segments provide a counter-balance and support structure for the new overhanging sidewalk.

In all, 400 precast concrete “Z” superstructure segments, 8-foot wide by 9-foot tall, that extend 13-feet and 400 precast concrete fascia panels, with various architectural finishes, measuring 8-ft-wide by 20-ft-tall with a thickness of 15 inches were manufactured and shipped by Oldcastle Infrastructure.

OLDCASTLE INFRASTRUCTURE PRODUCTS USED

- (400) “Z” Superstructure Segments: 8-foot wide by 9-foot tall, and extend 13-feet over the waterfront.

- (400) Fascia Wall Panels, with various architectural finishes, measuring 8-foot wide by 20-foot tall with a thickness of 15 inches. There are three different wall face designs throughout the project area, including tide lines, cobblestone and marine life textures.

USE OF PRODUCTS

Construction of a Seawall

WHY SELECTED

Precast concrete products reduced environmental impact, provided rapid construction, improved constructability, increased quality, and lowered life-cycle costs. Constructing Elliott Bay’s Sea Wall in this manner provided the most efficient and durable solution for the City of Seattle.

INNOVATION

Seawalls protect homes and businesses by withstanding some of the most violent conditions any marine product must endure.

The design and engineering of the fascia panels and specialty “Z” superstructure segments were essential to the seawall’s stability. The “Z” superstructures were a critical step in building the seawall and act as the concrete backbone of the new seawall’s cantilevered sidewalk and provide a counterbalance and support structure for the new overhanging sidewalk.

Providing a high quality, durable precast concrete approach to an interesting construction challenge – limitations of working in constrained area, tight construction schedule, and production within exacting tolerances of large precast components for field assembly – shows an excellent use of how precast concrete construction can accelerate a construction schedule and easily overcome demanding challenges of a project that other methods could not have achieved.

The state-of-the-art precast concrete seawall system reduced environmental impact, minimized the impact on adjacent piers, provided rapid construction, improved constructability, increased quality, and lowered life-cycle costs.

Find out more about Oldcastle Infrastructure Precast Concrete Seawall Systems.

Download Full Case Study

Onelift RC509 Pump Station used to Maximize Holding Capacity

Manheim, PA

DESIGN & CONSTRUCTION TEAM

General Contractor: Ashlin Woods

Owner: Spooky Nook Sports Complex

Precast Manufacturing Plant: Oldcastle Infrastructure, Spokane, Wash.

Utilizing the vacant 14-acre Armstrong building in Manheim, PA, along with its 65 surrounding acres; Owner Sam Beiler has created a facility to host 20-plus sporting programs, including the Women’s USA Field Hockey Team. The sporting complex opened last year, and this year a complementary Hotel and Restaurant expansion is being completed at the East Hempfield Twp., Lancaster County, PA facility.

Beiler is adding a new 130-room Warehouse Hotel and 260-seat restaurant to support the sporting complex, with new construction scheduled to be completed in the spring of 2015. Spooky Nook Sports is currently the largest sports complex in the country, and claims that it is not aware of any larger indoor sporting venue in the world.

THE CHALLENGE

Oldcastle Infrastructure was contracted to supply an additional turnkey submersible wastewater pump station to handle the additional wastewater capacity required for Spooky Nook Sports’ new 130-room hotel and 260-seat restaurant in East Hempfield Twp., Lancaster County, PA.

Oldcastle Infrastructure provided their OneLift RC611 pump station, with a 25 foot depth and storage capacity of 468 gallons per vertical foot, to accommodate the hotel expansion requirements of needing to maximize holding capacity within a very small area of land located adjacent to the hotel portion of the complex. The small footprint provided by Oldcastle Infrastructure’s OneLift pump station and the capa- bility to provide the required working volume and emergency storage was just the solution in the small space available.

The OneLift Pump Station is designed with an integral valve vault built into the unused top portion of the wet well, yielding a single-structure product, solving the problems of differential settlement found with the conventional 2-structure systems. In addition; the single-structure design, pre-assembled and ready for installation, significantly reduces the product footprint for sites such as Spooky Nook Sports with tight area restrictions. The manufacturing schedule of the OneLift was also a benefit to Ashlin Woods, the general contractor. The standard design and stock castings allowed Oldcastle Infrastructure to deliver the pump station just 6-weeks after release for production.

As this was the second station provided to this project by Oldcastle Infrastructure in as many years, the owner felt comfortable with the product. The owner wanted consistency at the sports complex and liked the quality and benefits of the One- Lift pump station. The first was installed during the initial construction of the sports complex in 2013 to service the needs of sewage transfer for a portion of the indoor complex and the outside soccer and field hockey rest rooms.

OLDCASTLE INFRASTRUCTURE PRODUCTS USED

- Qty (1) – RC611 OneLift pump station

- 25-foot-10-inch deep

- 468 gallon per vertical foot

USE OF PRODUCT

Sewage pump station to serve hotel facility with 135 rooms, bar & restaurant.

WHY SELECTED

The owner already had a OneLift station on site servicing another part of the facility. They wanted to maintain consistency. Also, the limited space for the sewage pump station made it an ideal fit for a OneLift pump station.

DATE OF INSTALLATION

March 4, 2015

INNOVATION

Single Structure design

The factory built OneLift pump station offers a monolithically cast valve vault, in what is typically an unused portion of the pump station. This results in a significantly smaller footprint – up to 50% smaller than conventional 2 structure pump stations – allowing it to fit tight sites. The innovative shape and structural design provides ample space for the interior valve vault, while in- creasing workable system volumes and decreasing the depth of the excavation. The single structure of the OneLift pump station eliminates any potential differential settlement issues, allows for a quick and easy installation by eliminating the typical two-tier excavation of conventional stations, and is proven to be a cost effective method of providing a high quality pump station solution with rapid and reliable delivery. With the OneLift pump station you get fast turnaround time on submittals; which include standard structural and mechanical components.

Find out more about the Oldcastle Infrastructure OneLift Pumpstation.

Download Full Case Study

Deep Creek Canyon Weekend Bridge Replacement

Broadwater County, Montana

DESIGN & CONSTRUCTION TEAM

General Contractor: Dick Anderson Construction, Great Falls, Mont.

Owner: State of Montana

Precast Manufacturing Plant: Oldcastle Infrastructure, Spokane, Wash.

The Montana Department of Transportation’s $2.75 million, Deep Creek Canyon Weekend Bridge Replacement project required reconstruction of three of eight deteriorating timber bridges built in the 1930s. The new Deep Creek bridges are located in Deep Creek Canyon between Townsend and White Sulphur Springs, MT.

To replace the three bridges, MDT and Morrison-Maierle Engineers selected Accelerated Bridge Construction {ABC) techniques to significantly accelerate the bridge reconstruction process. ABC entails prefabricating as many bridge components as possible to minimize road closures and traffic disruptions, promote traffic and worker safety, and improve the overall quality and durability of the bridges.

Morrison-Maierle and its partners designed the bridge foundation and the superstructure system as a complete, modular concrete system. The ABC system, consisted of precast concrete bridge superstructure and substructure elements, ensuring the bridges could be built during the weekend closures.

Built over three weekends, the new single-span, 54-foot- long, 31-foot 8-in. wide modular bridges were constructed in less than 60 hours per bridge. As a result, the MDT bridge construction project came in under budget, opened ahead of schedule, and did not interrupt the public’s traffic patterns.

PRODUCTS SUPPLIED

- (15) 53-ft-6.5-in.-long by 2-ft-3-in.-deep by 6-ft-4-in.-wide prestressed concrete tri-deck beams with the curbs and end diaphragms cast on.

- (6) 40-ft-3-in.-long by 3-ft-wide by 4-ft-tall, precast concrete grade beam abutments

- (12) 4-ft-4-in.-long by 2-ft-7-in.-tall by 1-ft-8-in.-thick precast concrete wingwalls

USE OF PRODUCTS

Construction of three single-span, 54-ft-long, 31-ft 8-in.-wide, modular bridges. Oldcastle Infrastructure assembling precast concrete elements for one of the bridges, at the precasting plant, and checking for precise precast component fit, prior to shipment.

INNOVATION

Complete, modular precast concrete bridge system. Superstructure and substructure elements consisting of three stem units with integral deck {tri-deck), grade beam abutments, and wingwalls were chosen to overcome the site and time problems at the bridge locations.

The top flange of the tri-deck concrete beams were designed to be the riding surface of the bridge deck.

This selection provided a high quality, durable precast concrete approach to an interesting construction challenge — limitations of working on a congested site, tight construction schedule, and production within exacting tolerances of large precast components for field assembly– shows an excellent use of how precast concrete construction can accelerate a construction schedule and easily overcome demanding challenges of a project that other methods could not have achieved.

AWARDS

Regional award in the 2015 America’s Transportation Awards, “Best Use of Innovation, WASHTO Region; 2015 Project of the Year by the Rocky Mountain Chapter of the American Public Works Association; 2015 Engineering Excellence Award, Structural Systems Category, by the American Council of Engineering Companies of Montana.

Find out more about Oldcastle Infrastructure Precast Concrete Bridge Solutions.

Download Full Case Study

Value Engineering Redesign

Ontario, California

DESIGN & CONSTRUCTION TEAM

General Contractor: CC Myers Inc.

Owner: City of Ontario Design

Engineer: T. Y. Lin International El Cajon, CA

Oldcastle Infrastructure Precast Product(s): Precast Concrete Fascia Beams Prestressed Box Girders

Oldcastle Infrastructure: Perris, CA

2014 DESIGN AWARD WINNER: BEST NONHIGHWAY BRIDGE

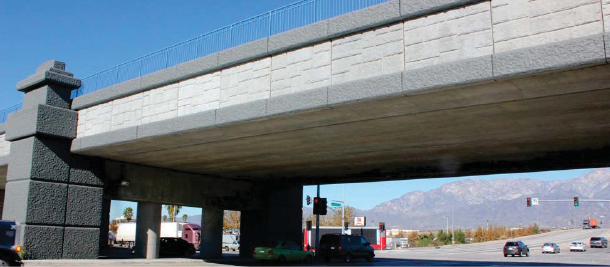

Located less than a quarter mile (400 m) south of a major freeway interchange, this busy railroad crossing is at the nexus of a significant freight and commercial truck corridor. Prior to construction, truck traffic exiting the freeway had to back up onto the freeway when a train blocked the grade crossing, causing major delays and a significant safety hazard.

Initially, the design featured a steel plate girder bridge with a steel plate forming the deck, says Jay Holombo of T Y. Lin International, the engineer of record of the redesigned underpass bridge. During the bidding phase an alternate superstructure design using precast prestressed concrete adjacent box girders was evaluated. The new underpass includes a two-span bridge measuring 171 ft long × 52 ft wide (52 × 16 m). A precast concrete T-wall based retaining wall system extends a half a mile (800 m) in either direction on both sides of the tracks to elevate the line while meeting right-of-way requirements.

THE SOLUTION

The redesigned two-span underpass bridge consists of 26 precast, prestressed box girders supporting ballast, waterproofing, and two mainline tracks. Ballast curbs were cast as an integral component of the exterior girders. Each span is transversely post tensioned at the quarter points within each span. Each 4-ft-wide box girder contains fifty-six 0.6-in.-diameter strands and relatively thick bottom and top flanges of 9 and 10 in., respectively, to meet the stringent American Railway Engineering and Maintenance-of-Way Association (AREMA) strength, service, and deflection requirements. A net upward permanent deflection of 3 in. at midspan was anticipated after placement of ballast. A buildup of rubberized asphalt was used to ensure sufficient transverse and longitudinal slope to maintain drainage off of the bridge.

Fascia beams are conventionally, used to support pedestrian walkways and communication conduit. To minimize the amount of formliner needed, the precast fabricator developed an innovative approach where the exterior was cast as 7.5-ft-long panel segments. These precast panel segments were then placed in the forms and cast with the rest of the fascia box girder, resulting in significant savings while meeting the aesthetic requirements of the project.

The benefit of using a precast concrete box-girder superstructure is that bridge maintenance painting operations are not required, as would be necessary for the as-designed steel girder system.

The value-engineering redesign of the North Milliken Avenue Railroad Underpass Bridge demonstrates that high-performance precast concrete is ideal for railroad bridge spans greater than 80 ft, and has better economy and faster production than equivalent steel spans. The City of Ontario and the surrounding community further benefited from an accelerated construction schedule and reduced future maintenance costs.

KEY PROJECT ATTRIBUTES

- Precast box beams demonstrated significant cost savings and reduced fabrication time while compared to steel plate girders

- Designers achieved faster delivery of the project with minimal effects on traffic

- Net savings to the project was approximately $900,000

PROJECT AND PRECAST SCOPE

- Project Cost: $5 million

- Bridge Length: 171 ft (52 m)

- 7 Feet deep (2.1 m) precast concrete fascia beams support maintenance walkways, railings, and communication conduit and precast, prestressed box girders

Find out more about Oldcastle Infrastructure Bridge Solutions.

New Fish Transport Barge Moorage Wharf at Lower Granite Lock and Dam on the Snake River

Whitman County, Wash.

DESIGN & CONSTRUCTION TEAM

Project: USACE Lower Granite Dam Fish Barge Wharf

General Contractor: The joint venture team of Garco Construction, of Spokane, Wash. and Total Site Services, of Richland, Wash., (TSS/GARCO)

Owner: Walla Walla District United States Army Corps of Engineers

Precast Manufacturing Plant: Oldcastle Infrastructure – Spokane, Wash.,

Selkirk, New York and Edgewood, Maryland, Colorado

This U.S. Army Corp of Engineers’ project involves construction of a new moorage facility and mooring dolphin at Lower Granite Dam in Whitman County, Washington.

This new fish transport barge moorage wharf adds to the existing moorage facility located along the shoreline of the Lower Granite Dam earthen fill section to accommodate operations, maintenance, and repairs of the existing barge feet. The old wharf no longer had the maintenance capacity for the additional and larger barges being put into service the past few years, and crane access was limited. Lower Granite is the first salmon collector dam on the Snake River, and thus the primary component of the fish transportation program. The juvenile fish are barged around this dam and the others of the Snake and Columbia Rivers for release below Bonneville Dam to reduce their mortality.

The new barge mooring wharf is fabricated using a combination of cast-in-place and precast concrete. The 300 foot long by 40 foot wide moorage wharf rests on two rows of pilings — 32 steel drilled shafts, 54 inch in diameter and 41 feet in length.

Large cap beams sit side-by-side, over the pilings in the water. The bumpers on the outside face of the large pile caps protect the structure. The small cap beams also sit side-by-side, opposite the large ones, and run along the toe of the earthen fill section of dam. Pre-stressed slabs span between the cap beams. The on-shore and in-water pile caps and slabs are connected together by a final 6 inch thick cast-in-place concrete slab and closure pour tying the cap beams into the drilled shafts.

THE PRECAST CHALLENGE

“This project required precision precast manufacturing. The precast cap beams and slabs elements, which are very large pieces, had to be manufactured within exacting tolerances, within fractions of an inch, in order to site assemble the precast components and achieve the requirements of the wharf specifications”, said Chuck Prussack, P.E., for Oldcastle Infrastructure Spokane. “We created a 3D virtual mock up based on as-built information to ensure that when the large precast concrete pieces arrived at the site they would fit with precision. In addition, there were special transportation requirements. The large cap beams required a truck and trailer measuring 138 feet long, and the road into the construction area was a narrow, winding two-lane country road with switch backs and a steep grade to the river.”

Oldcastle Infrastructure manufactured and shipped the eight-36 foot long by 7 foot wide by 13 foot high precast concrete large cap beams (140,000 pounds apiece), eight-36 foot long by 7 foot wide by 9 foot high small cap beams (104,000 pounds apiece), and thirtytwo- 27 foot long by 9 foot wide by 1 foot-6 inch thick pre-stressed concrete slabs (56,000 pounds apiece), for the barge moorage wharf project.

OLDCASTLE INFRASTRUCTURE PRODUCT USED

- (8) 36 foot long by 7 foot wide by 13 foot high precast concrete large cap beams (140,000 pounds apiece)

- (8) 36 foot long by 7 foot wide by 9 foot high small cap beams (104,000 pounds apiece)

- (32) 27 foot long by 9 foot wide by 1 foot-6 inch thick pre-stressed concrete slabs (56,000 pounds apiece)

USE OF PRODUCTS

Construct a new dam moorage wharf

WHY SELECTED

Precast concrete products reduced environmental impact, provided rapid construction, improved constructability, increased quality, and lowered life-cycle costs. Constructing the over water wharf in this manner provided the most efficient and durable solution for the USACE.

DATE OF INSTALLATION

Last Pieces October, 2014

INNOVATION

Providing a high quality, durable precast concrete approach to an interesting construction challenge — limitations of working in the river, tight construction schedule, and production within exacting tolerances of large precast components for field assembly– shows an excellent use of how precast concrete construction can accelerate a construction schedule and easily overcome demanding challenges of a project that other methods could not have achieved. The $6.9 million U.S. Army Corps of Engineers state- of-the-art precast/prestressed concrete wharf system reduced environmental impact, provided rapid construction, improved constructability, increased quality, and lowered life-cycle costs. Constructing the over water wharf in this manner provided the most efficient and durable solution for the USACE in addition to allowing service cranes to access any barge that is moored there.

Find out more about Oldcastle Precast Concrete Solutions.

Salem, MA

DESIGN & CONSTRUCTION TEAM

General Contractor: CRC Company Inc.

Owner: City of Salem

Total Project Value: $20,000,000

Oldcastle Infrastructure Value: $100,000

Precaster: Oldcastle Infrastructure

Manufacturing Facility: Oldcastle Infrastructure, Auburn, ME

The Salem Wharf Pier Project, a three-phase multi-purpose municipal port facility project, is expected to cost $20 million and will include a 390-foot pier with a 180-foot T-shaped portion. The City of Salem will continue its use as a ferry terminal and anticipates attracting other maritime enterprises including some of the smaller cruise ships as well as draw whale watching and fishing boats to the pier. Overall, the three-phase project is expected to cost $20 million.

CONSTRUCTION CHALLENGE

To construct a fixed “L” shaped pier designed to accommodate trucks with adequate maneuvering room, refueling and provisioning apron areas and space along the pier end to accommodate small coastal cruise ships (250 feet in length) and visiting ships.

PRECAST SOLUTION

Oldcastle Infrastructure designed and manufactured (68) Pre-Stressed Concrete Panels for the main pier leg which is 32 feet wide and 250+/- feet long and the 130 foot long pier “T” end that varies in width from 20 to 50 feet. The pier is designed to have a 10 ton mobile crane load capacity.

Find out more about Oldcastle Infrastructure Precast Concrete Solutions.

Download Full Case Study

The Pawtucket River Bridge

DESIGN & CONSTRUCTION TEAM

General Contractor: S & R Pihl JV

Owner: Rhode Island DOT

Total Project Value: $80,000,000

Precast Value: $1.9 M

Precaster: Oldcastle Infrastructure

Manufacturing Facility: Oldcastle Infrastructure, Rehoboth, MA

Due to aging Infrastructure and an increase in traffic the RI DOT needed to replace Pawtucket River Bridge. The new replacement bridge # 550 AKA the Pawtucket River Bridge carries I-95 over the Seekonk River between Exits 27 and 28.

The $80M Pawtucket Bridge replacement became a high priority in the fall of 2007 when deficiencies in the existing I-95 bridge forced RI DOT to lower the load rating on the existing structure and implement a major truck detour.

CONSTRUCTION CHALLENGE

RI DOT required the design team and contractor to reduce the construction time frame. In addition, closing Exit 27 was necessary to complete a phase of the project, RI DOT realized this closure needed to be as possible for the benefit of nearby businesses. and accelerate the reopening of this exit to help minimize the impact to downtown businesses.

PRECAST SOLUTION

RI DOT wanted precast and prefabricated sections that would reduce the construction time frame. Oldcastle Infrastructure supplied these components due to their structural strength, durability and fast-track construction ability.

Oldcastle Infrastructure Provided:

- Pre-stressed Deck Panles: (170+) 9’-8” W x 9” Thick x 16’-1”, 34’-0” and 40’ Long

- MSE Wall Panels

Find out more about Oldcastle Precast Bridge Components.

Download Full Case Study

US RT 2 Over B & M Railroad

Holyoke, MA

DESIGN & CONSTRUCTION TEAM

General Contractor: SPS New England

Owner: Mass DOT

Contract Value: $4,274,000

Precast Value: $700,000

Precaster: Oldcastle Infrastructure

Manufacturing Facility: Oldcastle Infrastructure, Rehoboth, MA

The project consisted of the replacement of the existing bridge carrying State Route 2 over B&M Railroad in North Adams. The existing concrete structure was constructed in 1930. The bridge is a three span plate girder with a total length of 121 feet. The structure was replaced in-kind with a new superstructure, founded on new precast concrete foundations consisting of piers and H-pile supported abutments. The bridge is approximately 52 feet wide and accommodates two travel lanes with shoulders and has a 5.5 foot sidewalk.

CONSTRUCTION CHALLENGE

Constructing the superstructure, which is the part of a bridge that spans the roadway, river, or railroad track that the bridge crosses. The bridge was constructed in two stages with one lane of U.S. Route 202 open to traffic. Conventional construction methods would have required long periods of lane closures for Route 2, resulting in long periods of congestion.

PRECAST SOLUTION

Precast concrete bridge components were selected for the construction method due to their structural strength, durability and fast-track construction ability.

Oldcastle Infrastructure Provided 70+ Precast Components:

- Footing

- Pier Caps

- Columns

- Crash Walls

- Approach Slabs

- Deck Panels

Find out more about Oldcastle Precast Concrete Bridge Components.

Download Full Case Study

for California Healthcare Facility Emergency Power

Stockton, CA

DESIGN & CONSTRUCTION TEAM

General Contractor: Bergelectric Corporation, Donlee Pump Co.

Owner: State of California

Precaster: Oldcastle Infrastructure

Manufacturing Facility: Oldcastle Infrastructure, Stockton, CA

Bergelectric Corporation, a nationally recognized electrical contractor, recently finished on-site construction of the “mission critical” electric power emergency/ backup generation system for the new $700-million California Health Care Facility in Stockton, CA.

Bergelectric, responsible for feeding power to the 144-acre site, supplied the core support facilities that serve as the backbone of operations. One of the most significant aspects of Berg’s role on CHCF-Stockton was the integration of normal and emergency power. Oldcastle Infrastructure supplied the specialized fuel storage system that feeds the 2 MegaWatt Caterpillar generators for emergency power.

CONSTRUCTION CHALLENGE

Oldcastle Infrastructure/ConVault sales team collaborated with customer/partner, Rich Hamilton, Special Projects Manager for Donlee Pump Co. and Berg’s Dan Winkels, project engineer for this project. The team designed and constructed a custom, sitespecific fuel supply system to feed six – 2 MegaWatt Caterpillar generators.

PRECAST SOLUTION

The fuel supply system includes one 2,000 gallon ConVault day-tank which was supplied by four large 10,000 gallon ConVault auxiliary storage tanks. The 5-tank array is fully monitored and auto-managed to provide re-circulation of fuel product and re-fueling of the day-tank “on demand”. Rounding out the comprehensive system design is a unique fuel filtration system, using a Velcon 60 GPM aircraft style filter module and differential pressure gauging/ compensating systems, to ensure fuel quality and purity.

EMERGENCY BACKUP POWER SYSTEM

SCOPE OF WORK

Oldcastle Infrastructure provided:

- 1 – 2,000 gallon ConVault Protected Fuel Storage Tanks (for genset day-tank)

- 4 – 10,000 gallon ConVault Protected Fuel Storage Tanks (main fuel storage)

All tanks systems are UL 2085 Listed per NFPA requirements, including fire, ballistic, vehicle impact and explosion protection.

Donlee Pump Co. provided and field installed all tanks, piping and equipment.

- ConVault meets uniform fire codes.

- Inspection for leaks is visual, which eliminates very expensive monitoring equipment needed to detect leaks underground.

- ConVault Vaulted Fuel Storage tanks are finished units – pumps and accessories are available – and can be set in place, ready for use.

- The ConVault tank can be customized to fit your needs. 250 – 500 – 1,000 – 2,000 – 4,000 – 5,200 – 6,000 – 8,000 – 10,000 – 12,000 gallons, split sizes also available.

Find out more about Oldcastle Vaulted Storage Tanks.

Download Full Case Study

Weigh Station Buildings Project

DESIGN & CONSTRUCTION TEAM

General Contractor: Telco Supply Co., Sulphur, OK

Owner: Oklahoma Dept. of Transportation

Precaster: Oldcastle Infrastructure

Manufacturing Facility: Oldcastle Infrastructure, Newnan, Georgia

Construction Services: Provided by Oldcastle Services

The Oklahoma DOT (ODOT) is constructing new state-of-the-art commercial truck weigh and inspection stations for heavy trucks entering Oklahoma. A total of nine POE weigh stations will be built along major highway entrances around the state’s border.

The $100 million dollar project consists of building eight permanent, manned stations at key ports of entry into Oklahoma, along with a ninth unmanned “virtual” station that will allow regulators to use special equipment to weigh and check trucks as they move along the highway.

CONSTRUCTION CHALLENGE

In collaboration with Telco Supply Company and the Oklahoma State DOT, Oldcastle Infrastructure provided a “turnkey” solution for the ODOT Port of Entry Precast Weight Station Buildings. Oldcastle Infrastructure’s turnkey scope of work consisted of the manufacturing, outfitting and installation of (2) two RCS 13830 Precast Concrete POE Buildings.

PRECAST SOLUTION

The ODOT, using metal office trailers in the past, knew it was essential, going forward, to provide a more secure and durable building to house the DOT employees that weigh and regulate the trucking industry on Oklahoma’s highways. They chose precast concrete construction as the solution.

The turnkey project involved the manufacturing and complete out-fitting of Oldcastle Infrastructure’s RCS 13830 Precast Concrete Buildings with all specified equipment. In addition, the fully out-fitted buildings were shipped, off loaded and installed at the POE sites near Oklahoma City. The RCS 13830 Precast Concrete Buildings were manufactured at our Newnan, GA facility.

SCOPE OF WORK

Precast Structure

A. STRUCTURE ENGINEERING

Detailed engineering and drawings

B. PRECAST CONCRETE SHELL

Size: (1) RCS 1430 Light Weight Precast Concrete POE Precast Office Building

Outside Dimension: 30’ Long x 13’ 8” Wide x 10.1’ High

Finished Inside Dimension: 29’ Long x 12’ 8” Wide x 9’ High

Weight: Approximate finished weight: ~82,700 pounds

Specifications:

Floor load: 200 PSF

Roof load: 60 PSF

Wind load: 150 MPH, Exp “C”, I=1.15

Bullet Resistance: UL752 Level 4 Equivalent (.30-06 at 15 Ft.)

Fire rating: Two Hour Equivalent

Seismic Zone: Up to 50% Gravity acceleration per IBC2006. Higher ratings are available to 300% Gravity acceleration

C. FINISHES

Exterior Walls: Solid Precast Concrete, 4” Thick with Textured Thorocoat finish

Interior Wall & Ceiling: Nudo White 1/2“ FRP board

Insulation: R-11 in walls and ceiling

Floor: Vinyl composition tile with rubber base molding

Roofing: White Elastomeric coating

Stud Partition Walls: Restroom & Closet walls

D. DOORS AND OPENINGS

Doors: (2) 3’-6” x 7’-0” 16 gauge steel door with 14 gauge steel frame

Locks: High Security Lockset with changeable core and Panic hardware

Other Door Hardware: (2) NRP Stainless steel hinges, anti-pick plate; kick plate, hydraulic door closer, weather strip, aluminum threshold, door sweep

Door Hood: (2) 54’w x 30” d door rain hoods, (2) Door drip cap

Interior Doors: (2) 3’ x 7’ Interior steel doors with hardware

Windows: (5) 5’ x 4’ Shatterproof Tinted Windows rated 150 MPH with 1- 5/16” tempered, tinted, hurricane resistant glass

E. POWER

Power Service: 200A 1Ø 120/240V

Disconnect Switch: (1) SQ D, D224NRB, 200A Exterior Disconnect Switch

Main Distribution Panel: (1) SQ D NQ series, MB panel, 200A 1Ø, 40 space

Surge Suppression: (1) Raycap/AC Data B82XXR-G at MDP

Convenience Receptacles: (6) 20A, 125V

Dedicated Receptacles: (~32) 120V, 15A Receptacles

Exterior GFI Receptacle: (2) 20A, 125V

F. ENVIRONMENTAL SYSTEM

HVAC: (1) 3 Ton, 240V, 1Ø wall mounted HVAC system

Controls: (1) Auto heat/cool thermostat controller

Restroom Exhaust fan: (1) Restroom exhaust fan

G. ALARMS

Alarms: (1) 25 pair split 66 block in storage room with intrusion smoke

H. LIGHTING

Interior:

(4) 4’ 2 tube Lithonia fluorescent light fixtures with acrylic lens covers

(2) 2’ x 2’ surface mtd fluorescent fixtures

Exterior: (2) 100W HPS Exterior light with photocell Lithonia TWA series

Emergency: (2) Emergency fixture with dual flood lights

Switches: (2) 20A light switches

I. GROUNDING

Grounds: Standard Commercial service grounding per NEC.

K. ADDITIONAL ITEMS

Telco, Computer, Radio: Install other conduits only as required

Counter: Plastic laminate counter with ledge

Storage shelves/Cabinet: Plastic laminate storage shelves in storeroom & storage cabinet in restroom

Restroom: Block outs for plumbing & floor drain provided by Oldcastle

IT equipment box/cabinet: IT equipment box/cabinet in storage room

Find out more about Oldcastle Precast Concrete Building Solutions

Download Full Case Study

Surge Tank Vault Installation Project

Rockville, Maryland

DESIGN & CONSTRUCTION TEAM

General Contractor: CPP Construction

Owner: The City of Rockville – Public Works

Contract Amount: $275,000

Precaster: Oldcastle Infrastructure

Manufacturing Facility: Oldcastle Infrastructure, Fredricksburg, VA

The project consists of the manufacture and installation of a precast concrete vault for the new hyrdo-pneumatic surge tank at the Glen Mill Pump Station. The surge tank is a critical piece of the surge suppression system that protects the City’s 24- inch water transmission main and the Glen Mill Pump Station. The Glen Mill Pump Station has a capacity of 10 MGD and pumps through a 6-mile-long, 24” transmission main that operates at pressures up to 190 psi.

The surge tanks work in concert with air release valves, which protect the City transmission main from damaging pressure surges that may occur during service disruptions such as power outages at the water treatment plant or the pump station.

The surge tank was installed in an underground precast concrete vault at the Glen Mill Pump Station to avoid visual impact on the adjacent residential community.

PRECAST SOLUTION

Oldcastle Infrastructure manufactured the 12’ wide x 25’ long x 11’4” deep precast concrete tank vault at their Fredricksburg, VA precast plant.

The 102 ton structure was designed in three pieces with a 3 way split slab and separate sump pit. The largest piece was the 37 ton base.

Oldcastle Infrastructure, Inc. and CPP Construction installed the liquid containment vault in one afternoon using a 300 ton hydraulic crane.

AWARD OF CONTRACT

February 6, 2012

SCOPE OF WORK

Precast Structure

A. STRUCTURAL ENGINEERING

Detailed engineering:

Drawings: Detailed drawings

B. PRECAST CONCRETE PRODUCT

Size: 12’ wide x 25’ x 11’4” deep tank vault

Concrete: 5,000 psi concrete

Weight: Approximate finished weight: 102 Tons

C. INSTALLATION

(3) Precast concrete components using a 300 ton hydraulic crane

Find out more about Oldcastle Infrastructure Liquid Containment Vaults

Download Full Case Study

Portsmouth, NH Project

DESIGN & CONSTRUCTION TEAM

Owner: Paul McInnis, Inc

PA DOT Contract Amount: Stoltze & Ehre LLC/Summit Engineering

Precaster: Oldcastle Infrastructure

Manufacturing Facility: Oldcastle Infrastructure, Auburn, ME & Rehoboth, MA

10 State Street Condominiums is a 10,000- SF, three-story, four unit condominium building built on a precast concrete pier constructed of precast pile caps, beams and pre-stressed panels located over water at pier II/10 State St. in Portsmouth, NH.

The four units range in size from 3,542SF to 4,791SF. There is also a deck lounge area and garden rooftop area that can be used by all of the homeowners. Each unit with also comes with two garage spaces and offers one-floor living with elevator access.

CONSTRUCTION CHALLENGE

Located over water, this project was challenged with fast moving currents, construction phasing to accommodate a small site, and coordination with concurrent abutting construction projects.

PRECAST SOLUTION

Precast concrete beams, pile caps, and pre-stressed slabs were selected for the construction method due to their structural strength and durability.

Oldcastle Infrastructure Provided:

- (61) Precast Beams with (53) Unique Types

- (44) Precast Pile Caps with (15) Unique Types

- (50) Pre-stressed slabs with (34) Unique Types

- The Project incorporated over 20 different beam to pile cap connection detailsDownload Full Case Study

Oldcastle Infrastructure has the expertise to set your shelter in some of the roughest terrain where conventional deliveries just cannot be done. What we can do for you: Bring in a crawler to site that can navigate up to a 30% grade; Navigate hairpin switchbacks; Unload shelter on foundation without the use of a crane.

Oldcastle Infrastructure is capable of leading and executing some of the most logistically challenging remote construction projects. Our professional team has successfully delivered projects in Oregon, Colorado and California.

Even the most logistically challenging projects and schedules are handled deftly thanks to the practical skill, technical insight and organizational prowess of the Oldcastle Infrastructure team.

Our team’s experience with managing operations to high environmental standards, and safety commitment has given us a solid reputation for safely completing logistically challenging projects, often in remote areas, with great quality, on time and within budget.

Oldcastle Infrastructure recently completed the challenging co-location site at Walker Mountain, Chemult, Oregon for American Tower Corporation.

Oldcastle Infrastructure provided turnkey deployment of a 20’ x 49’ co-location shelter.

Attention to quality and detail was central to completing a new substation communications site on top of Baker’s Peak, Slide Mountain, Yuma, Arizona for the U.S. Military and the Co-location Shelter on Iron Mountain, California for Motorola.

“I have no words for you guys but THANKS….Downy and Boise sites wouldn’t have been possible without your help and professionalism.”

Alex Mouledous

Network Deployment Engineer-Aircell LLC

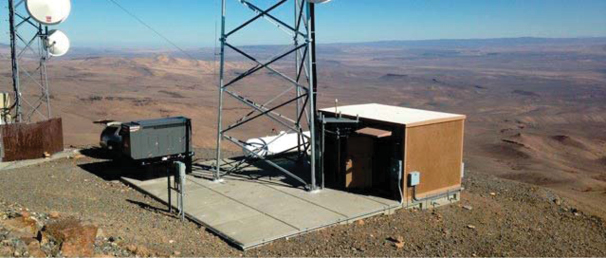

COMMUNICATIONS SUB-STATION – BAKERS PEAK COMPLEX

Slide Mountain, Yuma, Arizona

Oldcastle Infrastructure provided full turnkey services for the Marine Corps Air Station-Yuma, Arizona Bakers Peak Complex which included a 30 x 32 communications shelter and precast modular foundation blocks known as Cell Blocks.

Although Baker’s Peak was on a remote mountaintop with limited access Oldcastle Infrastructure demolished the old site and towers, prepared the new site, installed a precast cell block foundation, three communications towers and a precast 110 m2 Maxi-Mod Shelter. Each of the Maxi-mod sections brought up weighed 25 tones. The project was completed in eight working days and the clients were so pleased with the results that Oldcastle Infrastructure was awarded two further projects.

- Communications Shelter = (3) three piece ( 10’w x 32’L per section) precast concrete sectional building

- Shelter was fully outfitted with electrical, HVAC, alarms

- Three Towers: (2) two 50’ tower poles and (1) one 75’ tower pole

CO-LOCATION SHELTER AT WALKER MOUNTAIN

Chemult, Oregon

Oldcastle Infrastructure recently completed the challenging co-location site at Walker Mountain, Chemult, Oregon for American Tower Corporation. Oldcastle Infrastructure provided turnkey deployment of a 20’ x 49’ co-location shelter.

The 20×49 five piece co-location shelter was engineered and manufactured by Oldcastle Infrastructure for seismic zone: 150% G. The outside dimension is 50’-10” long x 20’-10” wide x 11’-2” high and the finished inside dimension– 50’-0” long x 20’-0”wide x 10’-6” high.

The turnkey project included total outfitting of the co-location shelter from installation of all electrical, environmental systems, alarms, lighting and on-site delivery and installation, in addition to on-site architectural enhancements.

IRON MOUNTAIN

Oldcastle Infrastructure completed the challenging turnkey deployment co-location site at Riverside County on Iron Mountain, CA for Motorola. In addition, Oldcastle Infrastructure erected a Motorola supplied 80’ Saber tower on site.

“My thanks for allowing me to watch them setting the maxi-mod at Black Mountain. It was very impressive and obvious that you guys can put a building anywhere.”

Olan J. Wade, CISSP

MUOS Site Planning Engineering IPT Lead – General Dynamics C4 Systems

SAMPLE OF ADDITIONAL PROJECTS

Download Full Case Study

Discharge / Re-route to Toketee Lake, Douglas County, Oregon

Components

96” ASTM C-76 Class III – 882 LF

96” ASTM C-76 Class III T-Lock – 1,709 LF

108” ASTM C-76 Class III – 288 LF

108” ASTM C-76 Class III T-Lock – 144 LF

48” Tee Manholes – 3 Each

Oldcastle Infrastructure Nampa, Idaho Supplies 3,000 foot pipeline for Lemolo No. 2

Hydroelectric Development Project

OCTOBER 2011 – Douglas County, Oregon:

Oldcastle Infrastructure supplied 3,000 feet of precast concrete pipe, elbow , transition pieces and manholes for the out-flow pipe and the in-flow pipe of PacifiCorp’s Lemolo No. 2 tailrace re-routing project in Douglas County, Oregon . PacifiCorp, a PacifiCorp Company, was required to reroute the Lemolo No. 2 powerhouse discharge to Toketee Reservoir in accordance with the North Umpqua Settlement Agreement Section 5.4. After a seven year design process, construction of PacifiCorp’s Lemolo No. 2 tailrace re-routing project is almost complete.

Oldcastle Infrastructure provided a 108” diameter concrete pipeline that transitioned into 96” diameter concrete pipe and then back into 108” concrete pipe. The pipe is t-lok lined pipe in portions to meet hydraulic design criteria. The precast concrete pipe was manufactured in 12 foot lay lengths with numerous custom castings. The pipeline makes multiple turns and grade changes. Inlet and outlet pieces were poured with a steel rings cast into the pipe for their connection to a cast in place head wall. In addition, Oldcastle supplied three T-Top manhole pipe sections with 48” manhole being cast into the pipe section for access to pipeline.

The Lemolo No. 2 tailrace re-routing project consists of in-water construction of the cofferdam for the inlet and an outlet structure. To stay on schedule, they were built from both ends. The 3000 feet of pipe was buried along the Toketee-Rigdon road and across the Toketee recreation area. The pipe will carry 700 cfs from the Lemolo 2 plant tailrace and eliminate ramping in the Lemolo 2 full flow reach of the North Umpqua River. Weekly Brothers, Inc. is the general contractor overseeing the construction and McMillen LLC is the project engineer. The project is scheduled for completion at the end of October, 2011.

PROJECT DESCRIPTION

Construction of a 108” diameter concrete pipeline transitioning into 96” diameter concrete pipe and then back into 108” concrete pipe, providing a new tailrace water discharge reroute from the Pacificorp Energy’s Lemolo #2 powerhouse to Toketee Lake. The pipe is t-lok lined pipe in portions to meet hydraulic design criteria. Pipes are being wet cast in standard 12’ lay lengths, with numerous custom castings required. The pipeline makes multiple turns and grade changes. Inlet and outlet pieces are poured with a steel rings cast into the pipe for their connection to a cast in place head wall.

DESCRIPTION OF WHAT OLDCASTLE DID FOR THE PROJECT

Oldcastle Infrastructure purchased 4 new 12’ long forms, 3-96” and 1-108” diameter pipe forms. Oldcastle produced 4 pieces of pipe a day utilizing an elliptical cage for reinforcing. Two single miter elbows for pipeline turns were made and two transition pieces going from 108” to 96” pipe were also made. Three T-Top manhole pipe sections were made with 48” manhole being cast into the pipe section for access to pipeline. 8 ton Meadow Burke lifting inserts were cast into the pipe to facilitate handling, both in the factory and at the jobsite. Hydrostatic joint tests Were required on the pipe so we had to build massive bulkheads and hydrostatic test the joints. It required over 11,000 gallons of water for 108” pipe test. We also had to D-load test the pipe, which had to be performed in our Utah facility with shorter 8’ lengths. Total D-load requirement was over 100,000 lbs of force put onto the pipe. The contractor is providing their own transportation, hauling one pipe per load. The contractor is required to successfully joint test, in the field, each piece of pipe prior to installing the next pipe.

Find out more about Oldcastle Precast Concrete Pipe Products.

Download Full Case Study

HIGHLIGHTS

Project Location: Contact, Nevada

Owner: Verizon Wireless

Construction Manager: Complete Wireless Consulting

Design Engineer: PJ Ford Engineers

Oldcastle Product(s):

- Precast Concrete Manufacturer

- Pleasanton, California

- Precast Concrete CELL BLOCKS® Foundation

- 25 CELL BLOCKS Foundation

Telecommunications Site

- 81 Foot tall self supporting tower with 15-feet face width.

- 125.3 Inch diameter microwave dish at 59-feet AGL with ice shield.

- 103.4 Inch diameter microwave dish at 29-feet AGL with ice shield.

- Three wireless sectors with three antennas each at 77’ AGL.

- 11’-6” X 16’-11” equipment shelter.

- 1000 Gallon propane tank.

- 60 KW standby propane generator.

Complete Wireless Consulting Inc. was tasked by a major telecom carrier to secure a lease and entitlements for the installation of a wireless cell tower on Ellen D. Mountain near Contact, Nevada. At an elevation of 8614 AMSL, the site was located in the northeast corner of Nevada on land overseen by the Bureau of Land Management (BLM). The proposed lease area for the major telecom carrier was 35’ x 35’. All parties desired a dependable solution that required a minimal amount of equipment and labor resources.

The BLM would only permit a foundation that minimized disruption to the existing ground and allowed for future site removal with less impact on the land. The precast concrete, post tensioned, Cell Blocks patented foundation system met this criteria and was selected for this site to support the telcom equipment conditions and, in turn, minimized the safety concerns about unknown underground hazards at the auto repair garage. The business interruption was minimal.

Cell Blocks are an engineered foundation system made from individual precast concrete blocks that are assembled in various configurations and post-tensioned providing a foundation for a monopole and equipment.

THE DESIGN

Designed by engineering firm PJ Ford Engineers, 25 Oldcastle Infrastructure CELL BLOCKS were manufactured to create the 35-foot by 35-foot foundation for the major telecom carrier’s wireless cell tower, microwave dishes, antennas, equipment shelter and generator.

THE SOLUTION

Structural drawings and calculations were first provided to the carrier’s construction manager, Complete Wireless Consulting, and the precast foundation blocks were then fabricated at the precast manufacturing facility near Pleasanton, CA. Anchor bolts and templates were provided to the precast facility by the self-supporting tower fabricator. The post tension GR 150 galvanized steel bars, hex nuts and plates were ordered from DSI America, Inc.

Special equipment (straight truck with 4 drive axles) was used to expedite delivery of the blocks to the mountain top.

With the precast blocks fabricated, the post tension steel ready, the shelter set to ship and the tower fabrication completed, the installation date was set.

On that day, a crane was set up and the crew placed twenty-five Cell Blocks, within 6 hours, atop the prepared granular base material. The minimum allowable soil bearing requirement was 1500 psf. The post tension bars, hex nuts and plates were immediately inserted to begin the hydraulic post tensioning process which took two hours. Oldcastle Infrastructure provided a certified hydraulic pump and 100 ton jack to post tension the steel bars to the specified tension force.

The shelter, generator, tank and tower were set immediately after the blocks were post tensioned.

The advantage of the Cell Block foundation was that, once post tensioned, the foundation was instantly full strength. Oldcastle Infrastructure provided an experienced representative, on-site, for the duration of the block installation and post tensioning process. The representative was able to ensure proper construction and assure the quality of the completed foundation.

One crane set the blocks, shelter, generator, tank and the tower on a foundation that was immediately full strength.

COMPLETION

Complete Wireless Consulting was then provided with a final certification package that included: certification of all materials, structural design permit drawings, calculations and jacking forces. The foundation was designed to support loads per ANSI/TIA 222- Rev G, Structure Class II, Exposure Category C, Topographic Category 3 and wind velocity of 120 MPH.

Using post tensioned precast concrete CELL BLOCKS for this wireless facility helped to ensure the installation was extremely predictable and required a minimal amount of resources. A one-day foundation installation process meant the entire site could be built in less than one week.

OldcastleInfrastructure.com

Download Full Case Study